Spray coating for cement kiln preheater

A preheater and paint spraying technology, applied in the field of spray paint for cement kiln preheater, can solve the problems of material consumption equipment weight, high thermal conductivity of spray paint, limited application range, etc., achieve good anti-skin performance, reduce thermal conductivity coefficient, effect of low bulk density and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

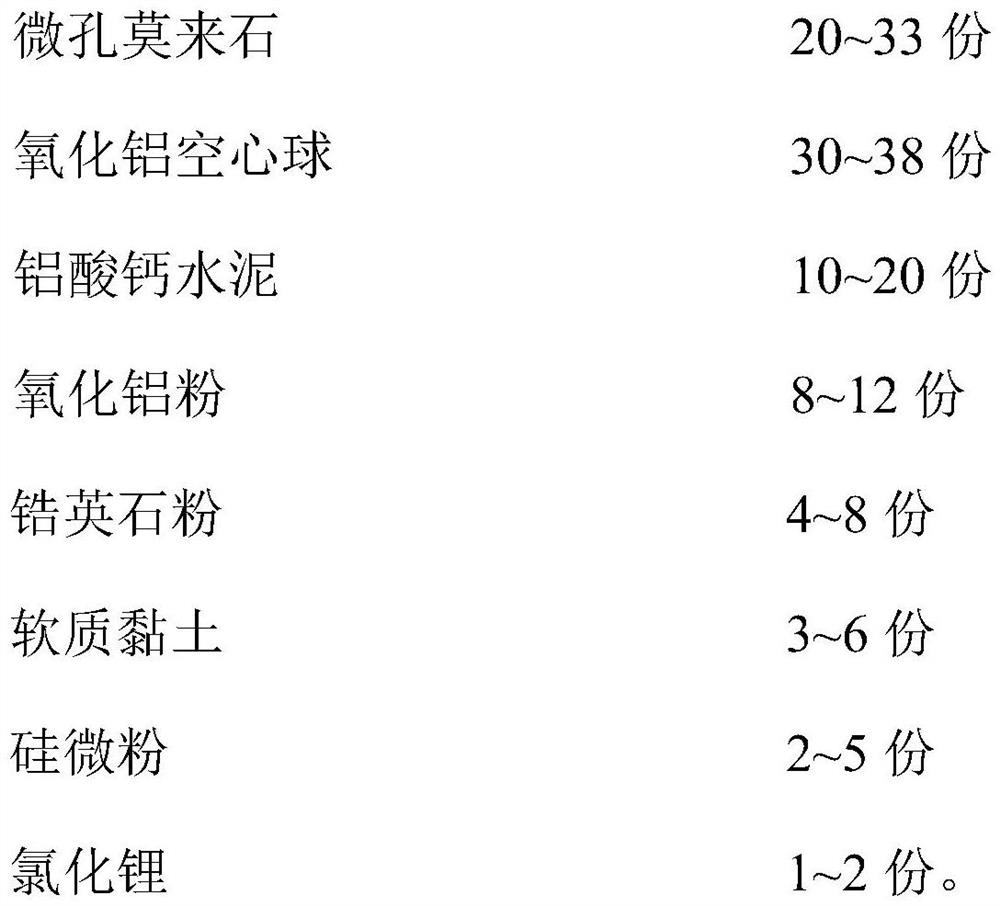

[0019] A spray paint for a cement kiln preheater, comprising the following components and parts by weight:

[0020]

[0021]

[0022] Wherein, Al in the microporous mullite 2 o 3 The mass percentage content is not less than 60%; the Al in the alumina hollow sphere 2 o 3 The mass percentage content is not less than 99%; Al in the calcium aluminate cement 2 o 3 The mass percentage content is not less than 50%; ZrO in the zircon powder 2 The mass percentage content of not less than 32%; SiO in the silicon micropowder 2 The mass percentage content is not less than 94%.

Embodiment 2

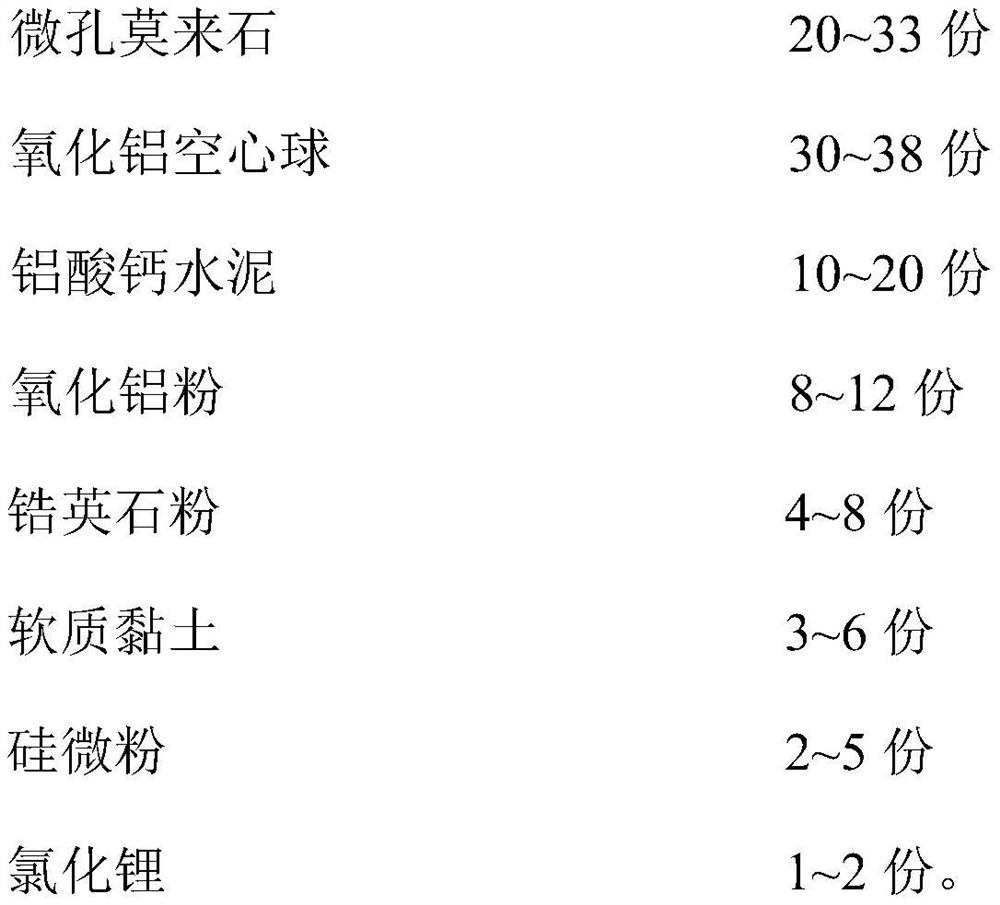

[0024] A spray paint for a cement kiln preheater, comprising the following components and parts by weight:

[0025]

[0026] Wherein, Al in the microporous mullite 2 o 3 The mass percentage content is not less than 60%; the Al in the alumina hollow sphere 2 o 3 The mass percentage content is not less than 99%; Al in the calcium aluminate cement 2 o 3 The mass percentage content is not less than 50%; ZrO in the zircon powder 2 The mass percentage content of not less than 32%; SiO in the silicon micropowder 2 The mass percentage content is not less than 94%.

Embodiment 3

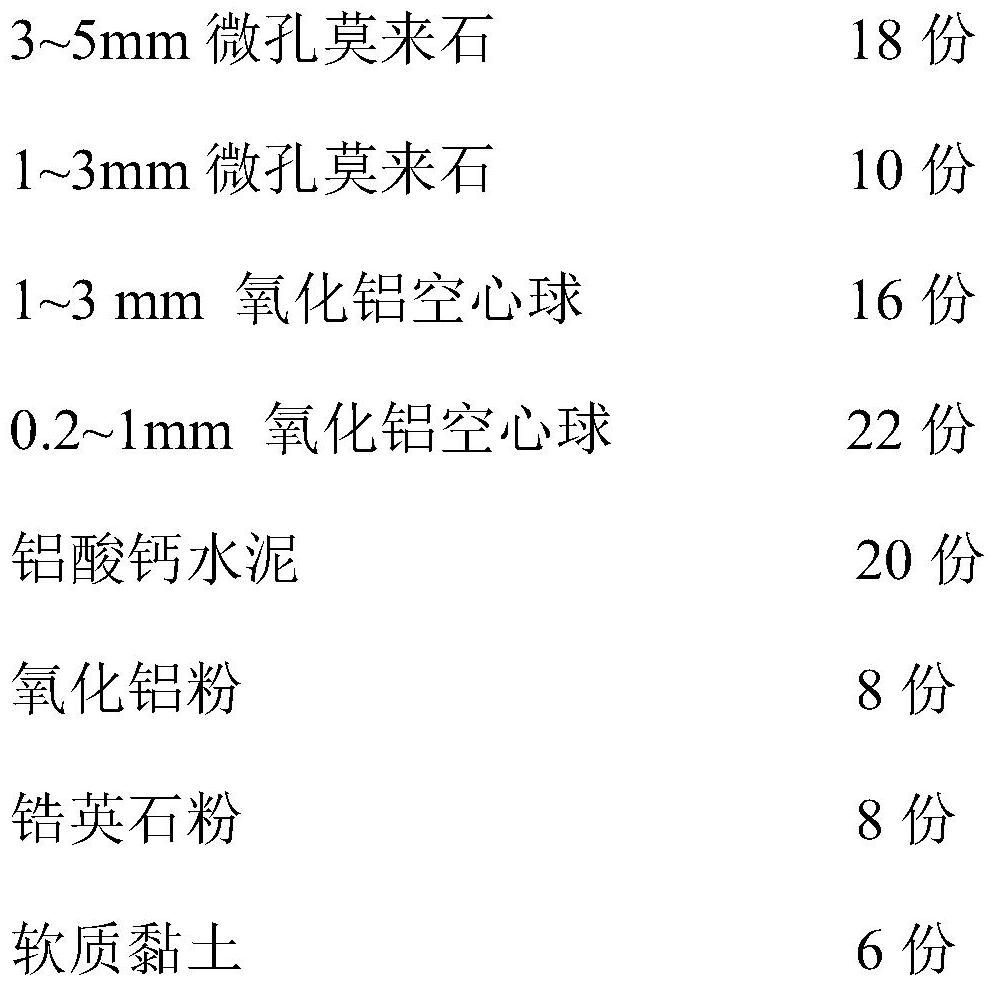

[0028] A spray paint for a cement kiln preheater, comprising the following components and parts by weight:

[0029]

[0030] Wherein, Al in the microporous mullite 2 o 3 The mass percentage content is not less than 60%; the Al in the alumina hollow sphere 2 o 3 The mass percentage content is not less than 99%; Al in the calcium aluminate cement 2 o 3 The mass percentage content is not less than 50%; ZrO in the zircon powder 2 The mass percentage content of not less than 32%; SiO in the silicon micropowder 2 The mass percentage content is not less than 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com