Method for manufacturing high-purity niobium pipe through repeated stretching forming for radio frequency superconductor cavity

A technology of multiple forming and multiple stretching, applied in electrical components, accelerators, etc., can solve the problems of waste of niobium material, high production cost, large tolerance of weld roundness, etc., and achieve the effect of ensuring the RRR value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, preparation high-purity RRR niobium tube

[0029] In this example, φ125×4.2mm high-purity niobium plate with RRR value of 340 is used as raw material, and a high-purity niobium tube with a specification of φ46×3×58mm is developed by the manufacturing method of multiple stretching.

[0030] Step 1, sanding and grinding the surface of the above-mentioned high-purity niobium plate to eliminate surface defects of the metal plate, and cleaning the surface of the plate to remove residual metal debris and processing oil on the surface;

[0031] Step 2, cut into circles according to the size of the high-purity niobium pipe material, and remove the burrs after cutting into circles;

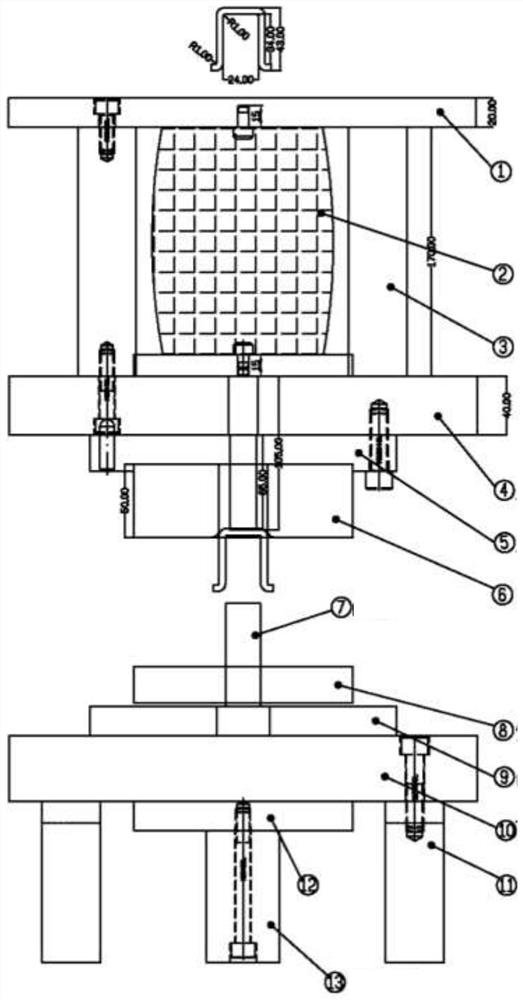

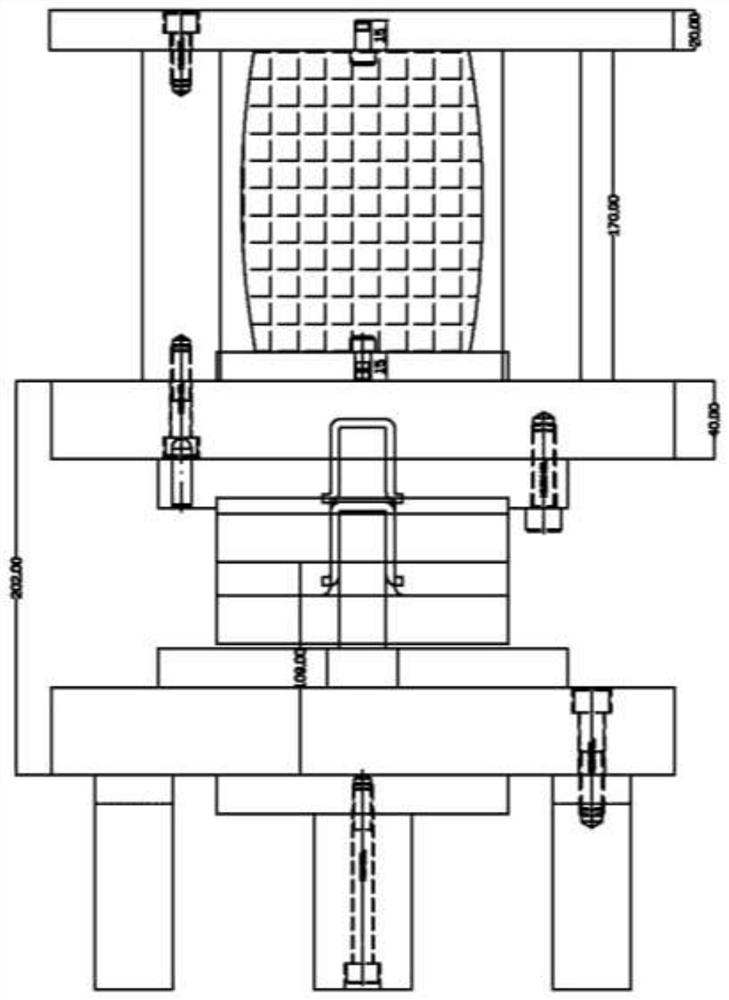

[0032] Step 3, install the multi-forming mold developed by Northwest Nonferrous Metals Research Institute on the press, and this mold has the functions of forming and returning materials. Apply stretching oil to the working part of the mold, put the round cut high-purity niobium plate...

Embodiment 2

[0040] Embodiment 2, preparation high-purity RRR niobium tube

[0041] In this example, φ360×4.8mm high-purity niobium plate with RRR value of 342 is used as raw material, and a high-purity niobium tube with a specification of φ110×3×152.4mm is developed by the manufacturing method of multiple stretching.

[0042] Step 1, sanding and grinding the surface of the above-mentioned high-purity niobium plate to eliminate surface defects of the metal plate, and cleaning the surface of the plate to remove residual metal debris and processing oil on the surface;

[0043] Step 2, cut into circles according to the size of the high-purity niobium pipe material, and remove the burrs after cutting into circles;

[0044] Step 3, install the multi-forming mold developed by Northwest Nonferrous Metals Research Institute on the press, and this mold has the functions of forming and returning materials. Apply stretching oil to the working part of the mold, put the round cut high-purity niobium p...

Embodiment 3

[0051] Embodiment 3, preparation high-purity RRR niobium tube

[0052] In this example, a φ200×5.2mm high-purity niobium plate with an RRR value of 338 is used as a raw material, and a high-purity niobium tube with a specification of φ42×3×88mm is developed by a manufacturing method of multiple stretching.

[0053] Step 1, sanding and grinding the surface of the above-mentioned high-purity niobium plate to eliminate surface defects of the metal plate, and cleaning the surface of the plate to remove residual metal debris and processing oil on the surface;

[0054] Step 2, cut into circles according to the size of the high-purity niobium pipe material, and remove the burrs after cutting into circles;

[0055] Step 3, install the multi-forming mold developed by Northwest Nonferrous Metals Research Institute on the press, and this mold has the functions of forming and returning materials. Apply stretching oil to the working part of the mold, put the round cut high-purity niobium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com