Microporous molecular sieve loaded bimetallic material for removing nitrogen oxide in diesel vehicle tail gas at low temperature, preparation method and application thereof

A technology for nitrogen oxides and diesel vehicles, applied in the direction of separation methods, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of no Chinese names, achieve the effects of inhibiting agglomeration, improving adsorption efficiency, and improving high temperature and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) NH 4 - Preparation of SSZ-13 catalyst

[0036] (1-1) Weigh 5~20g of commercial H-SSZ-13, place it in a tube furnace, and calcinate it in dry air at 520°C for 12 h for later use; add 20 g of ammonium sulfate to an appropriate amount of water (the solution concentration is 8 mol / L, solution volume 250mL), stirred for several minutes under ultrasonic conditions until ammonium nitrate was completely dissolved; weighed 40g of H-SSZ-13 molecular sieve calcined at high temperature and added to the above ammonium sulfate solution, then moved the mixed solution to magnetic stirring Stirring on the mixer at room temperature for 2.5 h (800 r / min), the stirred mixture was filtered to obtain a white solid, which was washed several times with deionized water. After repeating the above process 3 times, the obtained white solid was placed in an oven and dried at 160 °C for 20 h to obtain NH 4 -SSZ-13.

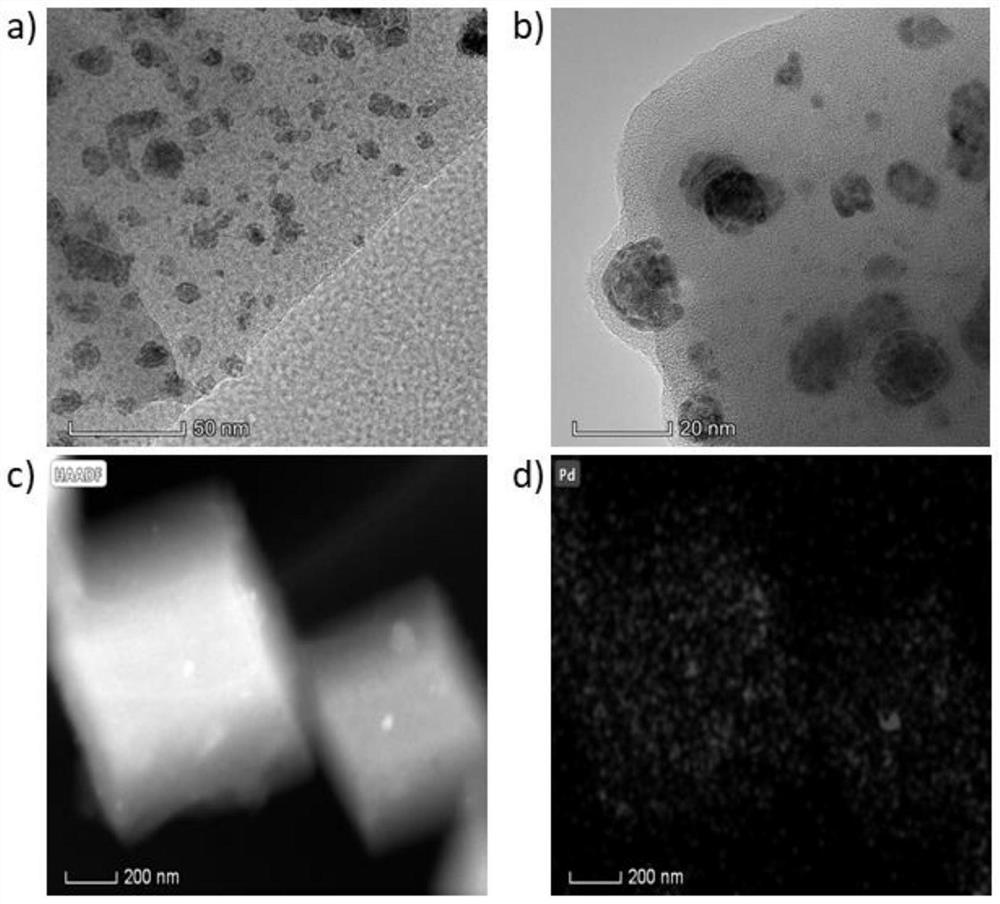

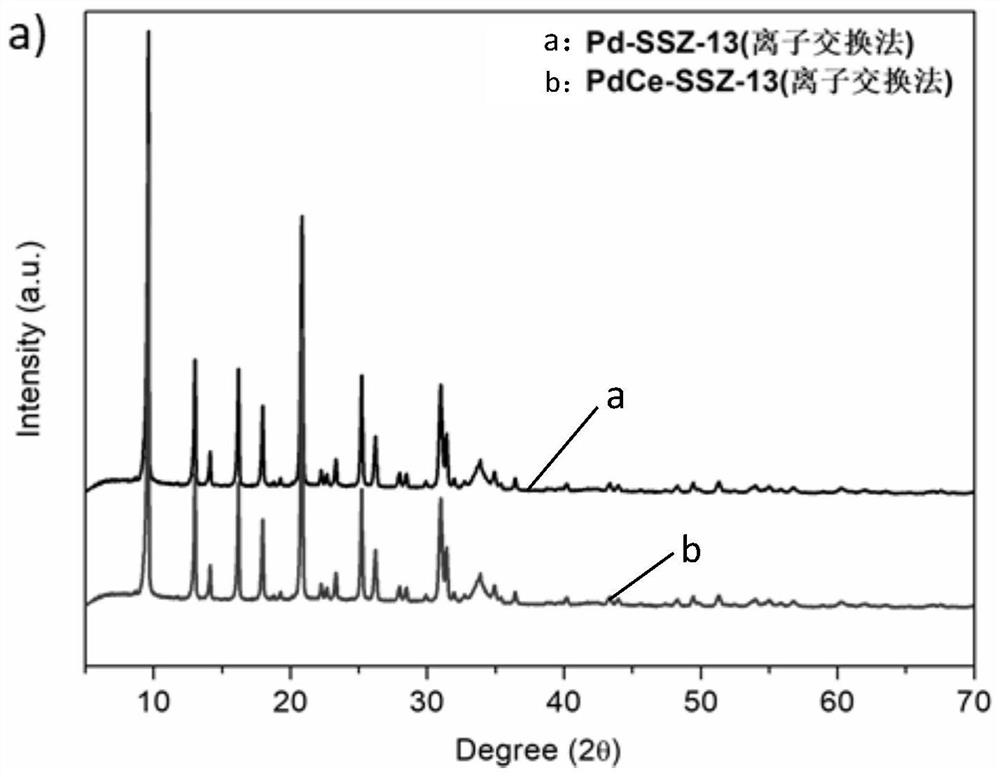

[0037] (1-2) The preparation method of Pd-SSZ-13 (ion exchange method) is o...

Embodiment 2

[0044] (1) NH 4 - Preparation of SSZ-13 catalyst

[0045] (1-1) Weigh 5~20g of commercial H-SSZ-13 and place it in a tube furnace, and calcinate it for 12 h under dry air conditions at 520 °C for later use; add 20 g of ammonium sulfate to an appropriate amount of water (the solution concentration is 8 mol / L, solution volume 250mL), stirred for several minutes under ultrasonic conditions until ammonium nitrate was completely dissolved; weighed 40g of H-SSZ-13 molecular sieve calcined at high temperature and added to the above ammonium sulfate solution, then moved the mixed solution to magnetic stirring Stirring on the mixer at room temperature for 2.5 h (800 r / min), the stirred mixture was filtered to obtain a white solid, which was washed several times with deionized water. After repeating the above process 3 times, the obtained white solid was placed in an oven and dried at 160 °C for 20 h to obtain NH 4 -SSZ-13.

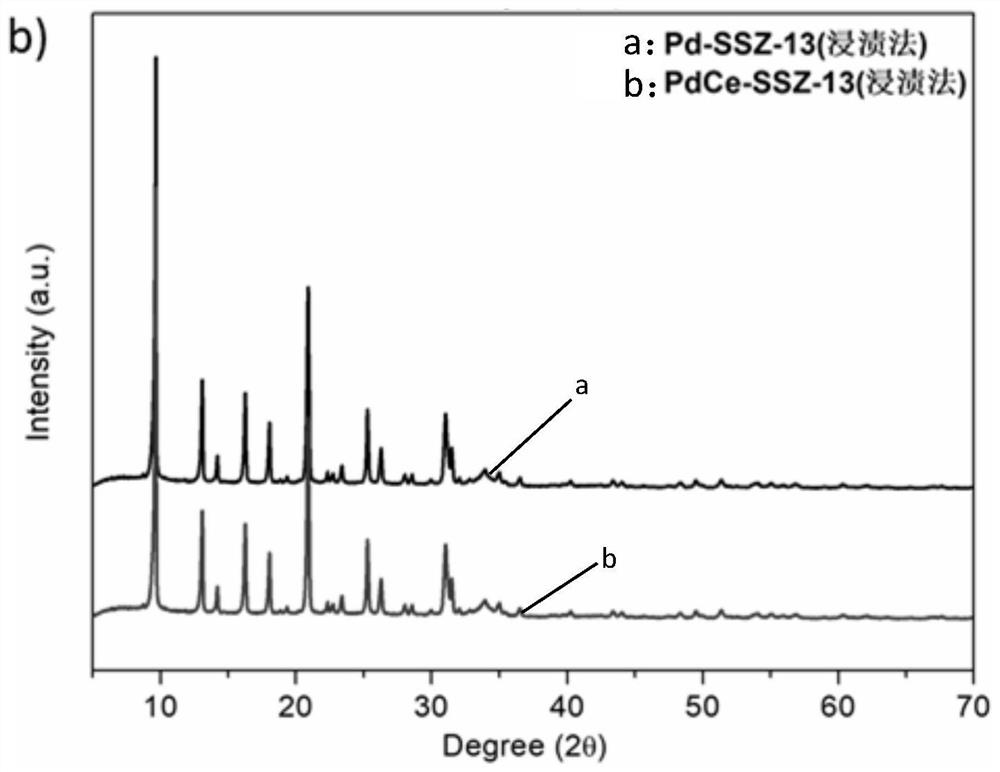

[0046] (1-2) The preparation method of Pd-SSZ-13 (dipping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com