Supported catalyst filter fiber for catalytically degrading pollutants in water and preparation method and application of supported catalyst filter fiber

A technology for supporting catalyst and filtering fiber, which is applied in the application field of catalyst filtering fiber and its preparation and degradation of organic pollutants, can solve problems such as difficult organic matter, and achieve the effects of low cost, no peculiar smell and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

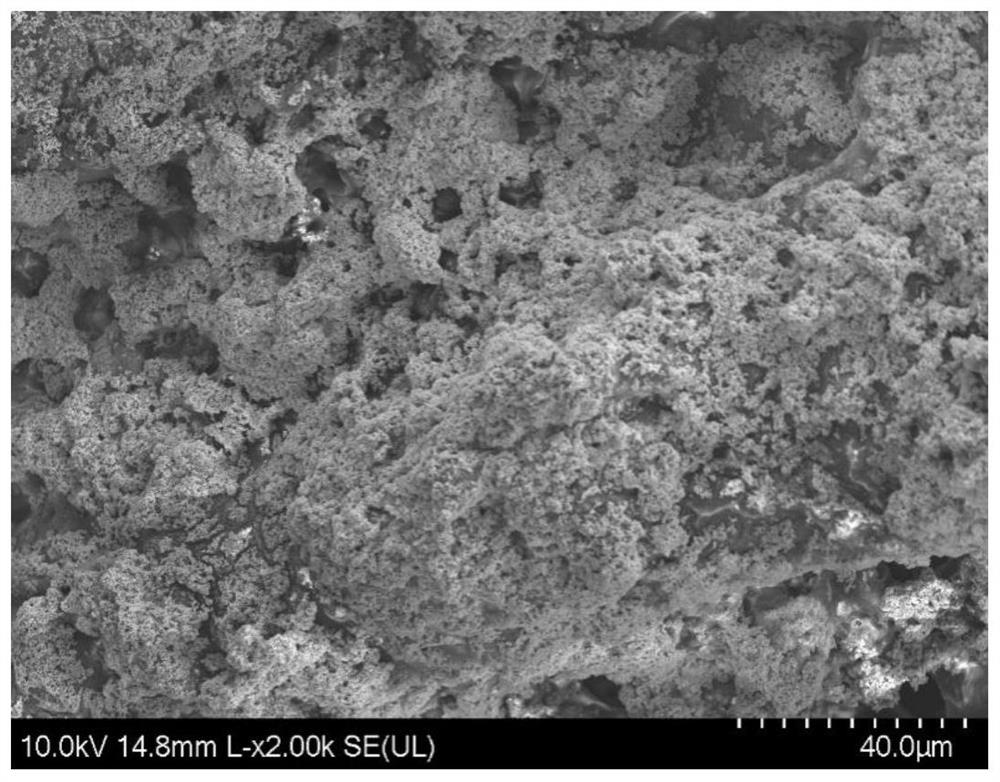

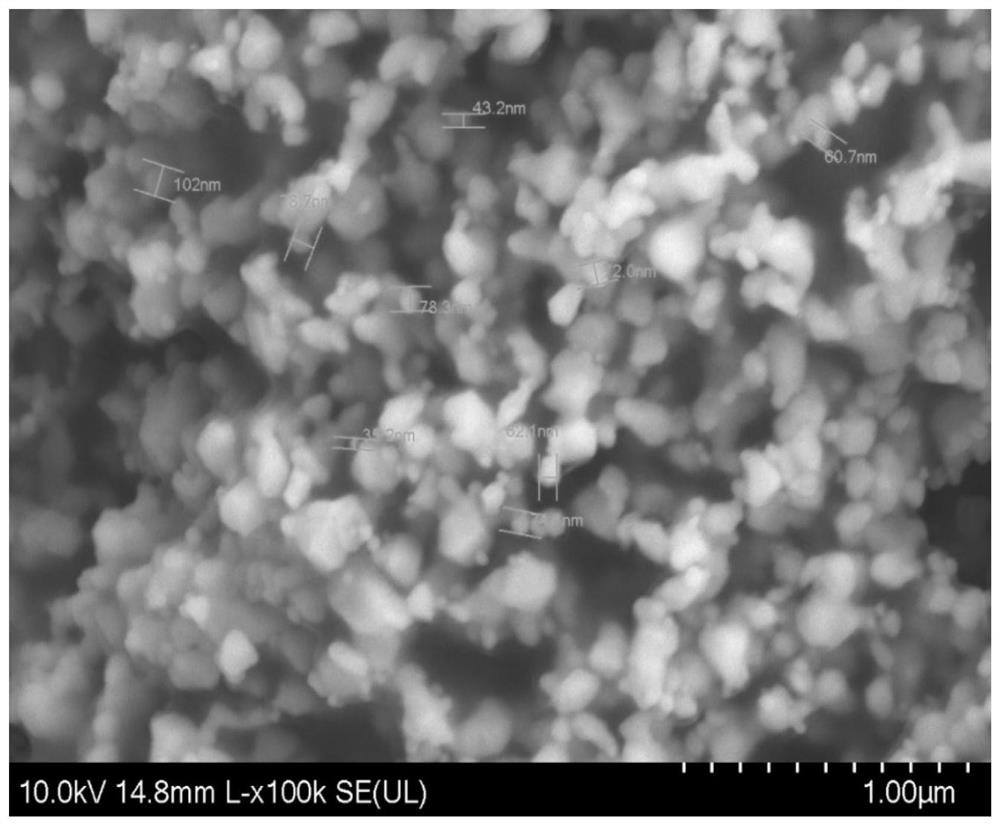

[0043] (1) Weigh 5.0kg of potassium permanganate, 4.0kg of potassium ferrate, 4.0kg of sodium oxalate, and 2kg of cobalt chloride in a reaction kettle, add 100L of distilled water, stir and mix evenly; then react hydrothermally at 120°C 7h, after the reaction, cool down to room temperature naturally, soak in distilled water and stir for 10-30min, after the material slowly settles, pour off the water in the upper layer, repeat the operation 3-5 times, until the water after cleaning has no color, clean it The material was dried at 110°C for 3 hours to obtain a catalyst;

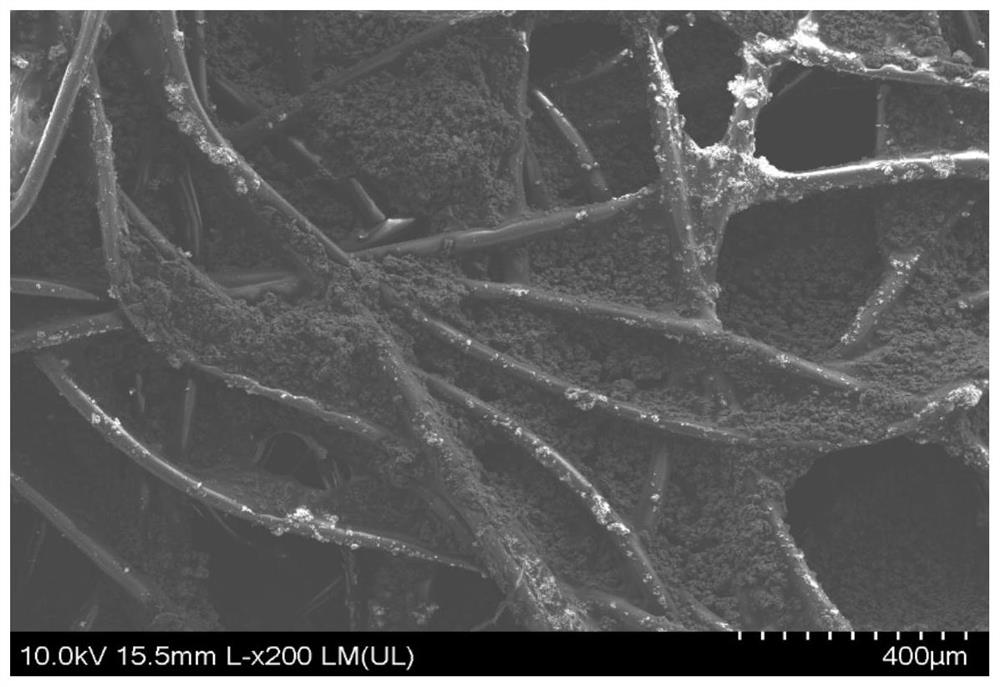

[0044](2) According to the mass ratio of catalyst: water: glue (polyurethane glue, model PU800, produced by Guangzhou Degong Mingxin Environmental Protection Technology Co., Ltd.) is 2:1:1.5, add the catalyst to the water, and ultrasonic for 15 minutes until the catalytic material is in the aqueous solution Form a uniform colloidal solution, then add glue to the solution, stir for 10 minutes, and obtain the glu...

Embodiment 2

[0049] (1) Weigh 5.0kg of potassium permanganate, 4.0kg of potassium ferrate, 4.0kg of sodium oxalate, and 2kg of cobalt chloride in a reaction kettle, add 100L of distilled water, stir and mix evenly, and then react hydrothermally at 120°C 7h, after the reaction, cool down to room temperature naturally, soak in distilled water and stir for 10-30min, after the material slowly settles, pour off the water in the upper layer, repeat the operation 3-5 times, until the water after cleaning has no color, clean it The material was dried at 110°C for 3 hours to obtain a catalyst;

[0050] (2) Catalyst: water: glue (polyurethane glue, model PU800, produced by Guangzhou Degong Mingxin Environmental Protection Technology Co., Ltd.) with a mass ratio of 2:1:1.5. Add the catalyst to pure water and ultrasonicate for 15 minutes until the catalytic material is in the aqueous solution. Form a uniform colloidal solution in the solution, then add glue to the solution, stir for 10 minutes, and ob...

Embodiment 3

[0055] (1) Weigh 5.0kg of potassium permanganate, 4.0kg of potassium ferrate, 4.0kg of sodium oxalate, and 2kg of cobalt chloride in a reaction kettle, add 100L of distilled water, stir and mix evenly, and then react hydrothermally at 120°C 7h, after the reaction, cool down to room temperature naturally, soak in distilled water and stir for 10-30min, after the material slowly settles, pour off the water in the upper layer, repeat the operation 3-5 times, until the water after cleaning has no color, clean it The material was dried at 110°C for 3h, and then dried at 110°C for 3h to obtain a catalyst;

[0056] (2) Catalyst: water: glue (polyurethane glue, model PU800, produced by Guangzhou Degong Mingxin Environmental Protection Technology Co., Ltd.) with a mass ratio of 2:1:1.5. Add the catalyst to pure water and ultrasonically until the catalytic material is in the aqueous solution Form a uniform colloidal solution, then add the glue solution to the solution, stir for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com