Connecting structure for control panel, motor control panel, stator assembly and motor

A technology of connecting structure and stator assembly, applied in the direction of connecting with control/drive circuit, etc., can solve the problems of harmfulness to human body and low production efficiency, and achieve the effect of reducing harmful gas, improving production efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

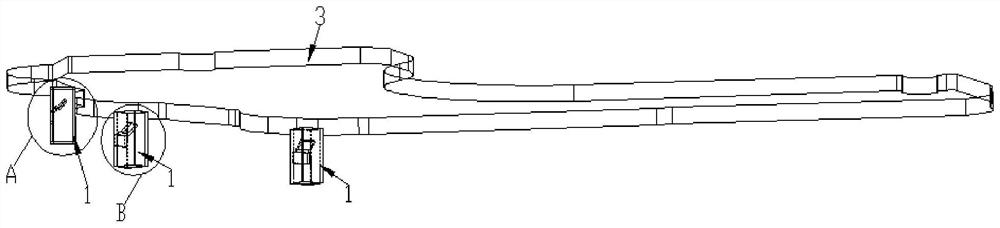

[0041] The connection structure for the control board provided by the present invention includes a matching foot 1 and an insertion foot 2, both of which are made of metal materials; the matching foot 1 and the insertion foot 2 are respectively welded on the motor control board 3 and the stator On the assembly: the number of mating feet 1 and insertion feet 2 is the same and the number of insertion feet 2 is three, and the lead wires of the stator assembly are respectively connected to the corresponding insertion feet 2;

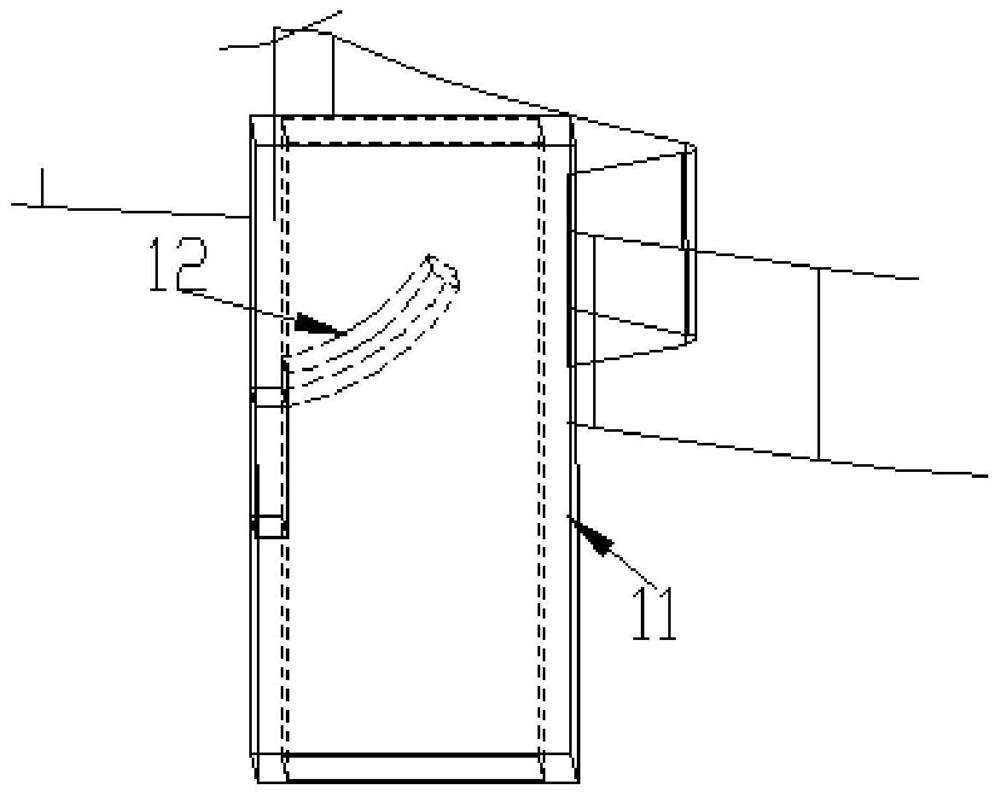

[0042] The mating foot 1 includes a cylindrical part 11 and an elastic part 12. The elastic part 12 is located in the cylindrical part 11; It is connected to the inner surface of the cylindrical part 11, and the other free end is bent toward the direction extending into the cylindrical part 11;

[0043] The insertion pin 2 includes a main body 21 and a snap-in portion 22, the snap-in portion 22 is connected to the main body 21 and there is an angle between t...

Embodiment 2

[0046] A motor control board, the motor control board 3 is connected to the stator assembly through the control board connection structure described in the first embodiment, and the motor control board 3 is provided with a mating foot 1 .

Embodiment 3

[0048] A stator assembly, the stator assembly is connected to the motor control board 3 through the connection structure for the control board described in Embodiment 1, and the stator assembly is provided with insertion pins 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com