Pointer type instrument automatic reading method based on radial gray scale

A technology for automatic reading and instrumentation, which is applied in the direction of instruments, biological neural network models, character and pattern recognition, etc., and can solve problems such as poor instrument reading results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

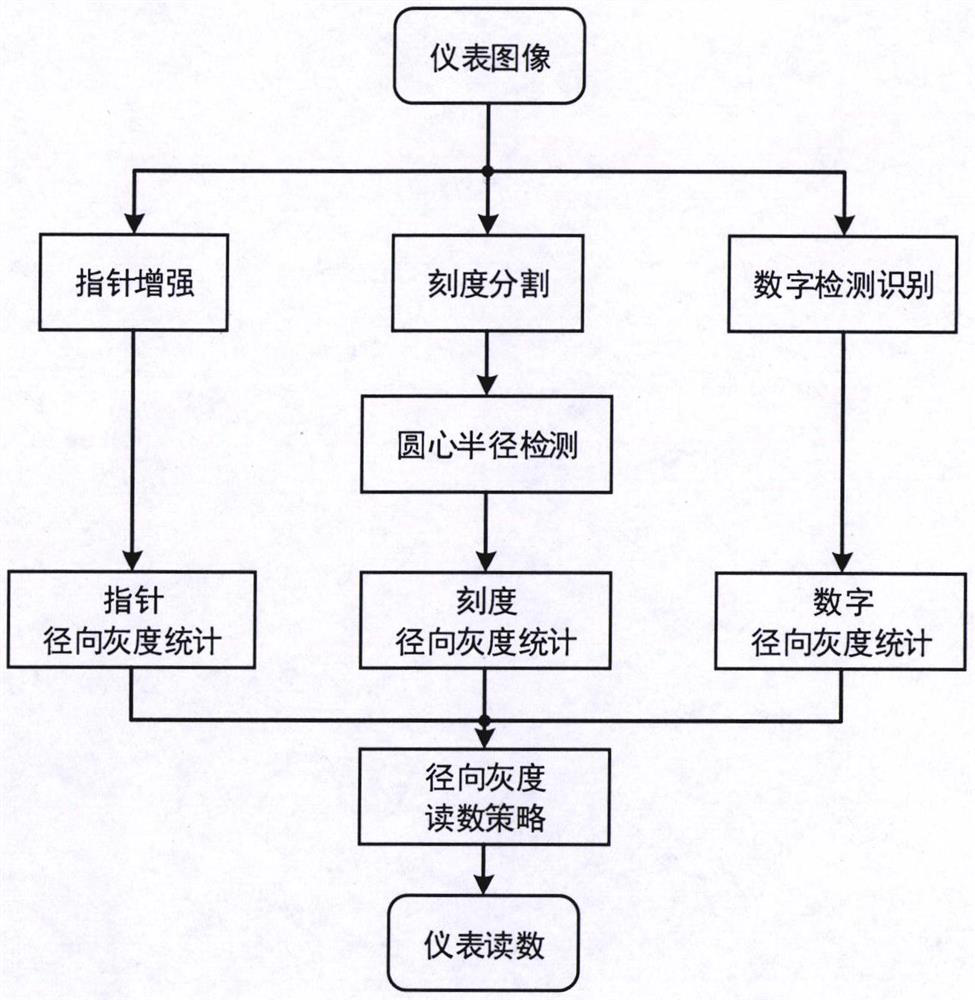

[0077] The following embodiment is an automatic reading method for radial grayscale statistics of a single-pointer instrument, and the complete flow chart of the method is as follows: figure 1 shown.

[0078] Step A, build an improved Unet dial scale line segmentation deep neural network, collect instrument images to make a data set and train the network, input the trained instrument image into the network to obtain the scale line segmentation results;

[0079] Step B, calculating the center coordinates of the dial and the distance from the scale to the center of the circle according to the scale segmentation results;

[0080] Step C, use yolov3 to detect the dial scale number category and position, and then determine the scale number by the mean-shift clustering method;

[0081] Step D, performing radial grayscale statistics on the instrument scale image, digital detection result image, and pointer thresholded image respectively, to obtain respective radial grayscale statist...

Embodiment 2

[0084] In this embodiment, on the basis of Embodiment 1, the specific process of the step A is as follows:

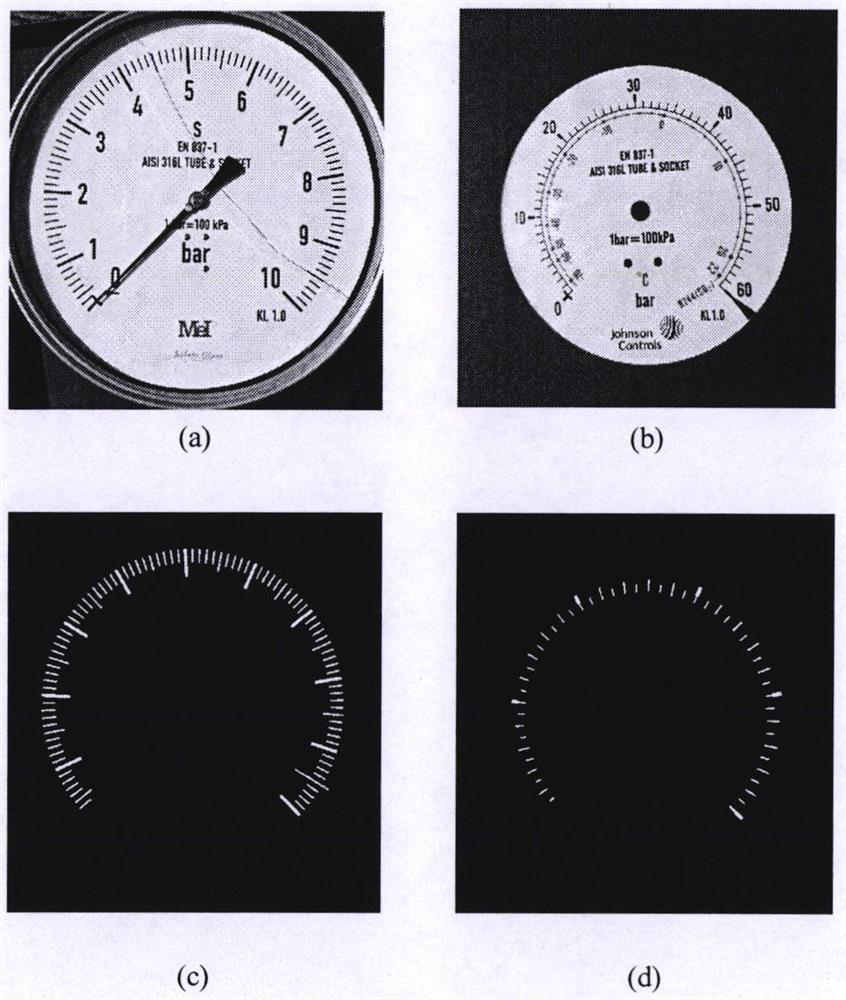

[0085] Step A1. Obtain the front single-channel image of the meter, normalize the resolution to 560*580, mark the meter scale pixels as 255, and mark the non-meter scale pixels as 0, a total of 25 images, including the instrument training image with the shell Such as figure 2 As shown in (a), the scale labeling results are as follows figure 2 As shown in (c); only the instrument training image of the dial is shown as figure 2 As shown in (b), the scale labeling results are as follows figure 2 as shown in (d);

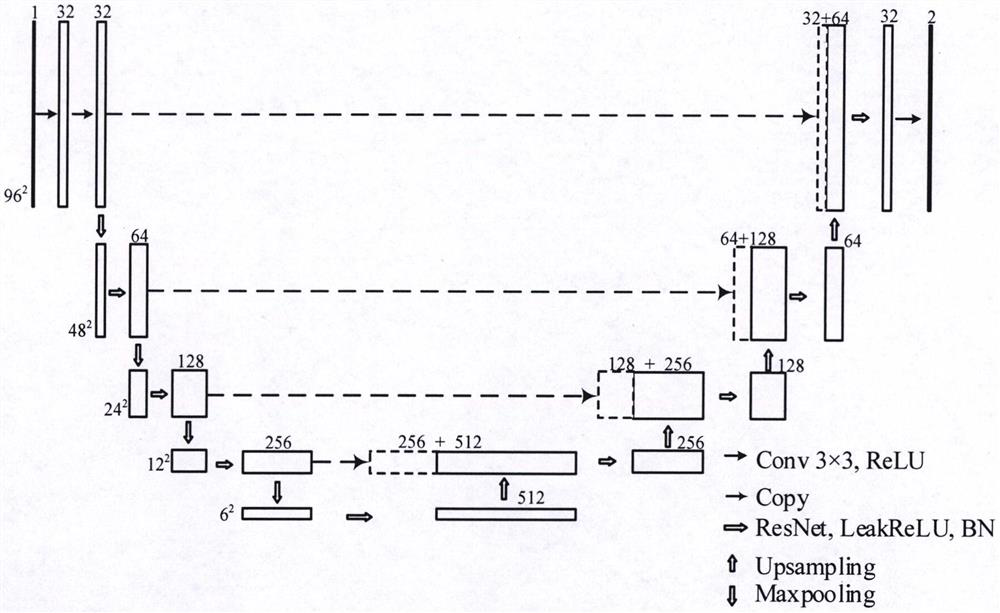

[0086] Step A2, such as image 3As shown, a scale segmentation network with cross-layer connections is constructed, with a total of 9 layers. The first layer consists of two ordinary convolution layers and a pooling layer. The 2-4 layers use the residual module whose activation function is LeakyReLU as convolution. Unit, in which the slope of the negativ...

Embodiment 3

[0089] In this embodiment, on the basis of Embodiment 1, the specific process of the step B is as follows:

[0090] Step B1. Set a threshold of 0.5 in the scale segmentation probability map. Pixels higher than the threshold are reserved as scale pixels. After thresholding, a scale binary image is obtained, and all connected domains C in the scale binary image are marked in turn. i ,, remove the noise connected domain whose connected domain area is less than 5;

[0091] Step B2, fitting all the pixel points in each connected domain to a straight line l i , find any two fitting straight lines l i and l j Intersecting intersection point coordinates D ij (x ij ,y ij ), respectively calculate the mean value μ of the horizontal and vertical coordinates of the intersection point x , μ y with variance σ x , σ y ;

[0092] Step B3. Transform the abscissa and ordinate samples of the intersection point into a standard normal distribution, and keep the abscissa X' at the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com