Sample sealing tube for protecting air sensitive sample as well as preparation method and application thereof

A technology for sealing sample tubes and samples, which is applied in the field of sample sealing tubes for protecting air-sensitive samples and its preparation. It can solve the problems that capillary tubes are not easy to prepare, cannot be used well, and the wall thickness is difficult to control, so as to achieve low overall price and easy sample preparation. Easy operation and easy sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

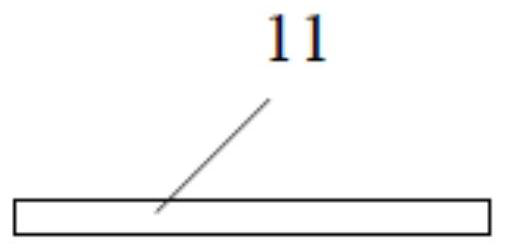

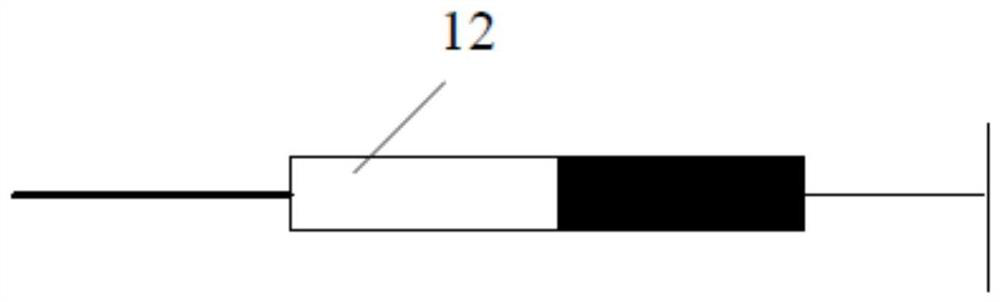

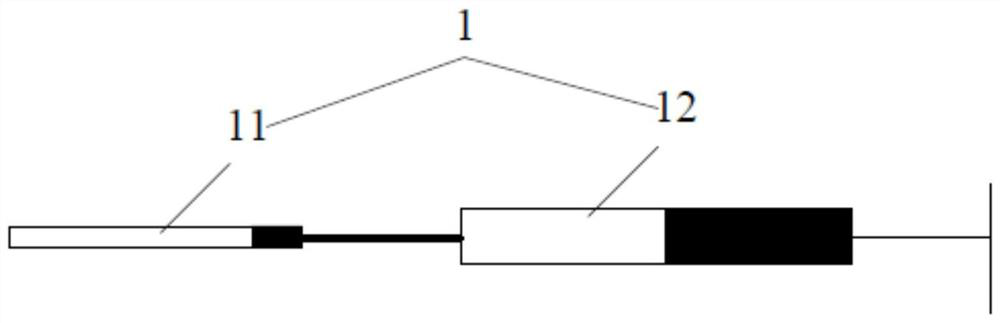

[0034] Such as Figure 1~3 As shown, a sample sealing tube for protecting air-sensitive samples includes a sample loading tube 11 and an auxiliary device 12 matched with the sample loading tube 11; one end of the sample loading tube 11 is connected with the auxiliary device 12, and the The other end is used to hold the sample; the wall thickness of the sample loading tube 11 is 5-50 μm.

[0035] Further, the wall thickness of the sample loading tube 11 is 5-50 μm. Preferably, the wall thickness of the sample loading tube 11 is 10-30 μm. More preferably, the wall thickness of the sample loading tube 11 is 20 μm. Through a large number of product experiments, the present inventor found that the sample loading tube 11 can be used to prepare the sample sealing tube 1, and the use of the sample loading tube 11 for sample loading will not affect the diffraction experimental data, especially for single crystal diffraction testing. Experiment; at the same time, the sample loading t...

Embodiment 2

[0042] A preparation method for a sample sealing tube for protecting air-sensitive samples, comprising the following steps:

[0043] S1. Prepare a sample loading tube 11 with a tube wall thickness of 5-50 μm and an auxiliary device 12 matching the sample loading tube 11;

[0044] S2, connecting one end of the sample loading tube 11 to the auxiliary device 12, specifically, inserting one end of the sample loading tube 11 into a microsyringe, and then performing single crystal sample loading after the stable connection;

[0045] S3, after the single crystal sample loading is completed, the sample loading tube 11 is firstly removed from the auxiliary device 12, and the two ends of the sample loading tube 11 are sealed;

[0046] The preparation method is simple and easy to operate. Although the diameter and wall of the tube used are smaller and thinner, compared with the capillary tube purchased regularly, the sample sealing tube 1 of the present invention is more suitable for the...

Embodiment 3

[0048] An application of a sample sealing tube for protecting air-sensitive samples in an X-ray diffraction test experiment, the sample sealing tube 1 is the sample sealing tube 1 described in Example 1. Among them, the most effective one is used in the X-ray single crystal diffraction test experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com