X-ray diffraction back-pressurizing penetration sample board capable of reducing preferred orientation

A technology of preferred orientation and sample plate, applied in material analysis using radiation diffraction, material analysis using wave/particle radiation, measuring devices, etc., can solve problems such as cumbersome back pressure method, sample sinking, sample preparation failure, etc. Achieve accurate X-ray diffraction patterns and test results, simple and convenient sample preparation, and reduce errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

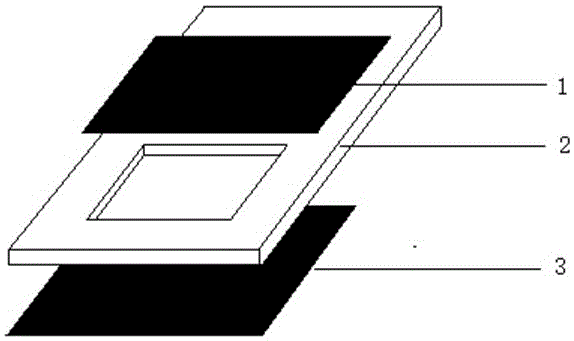

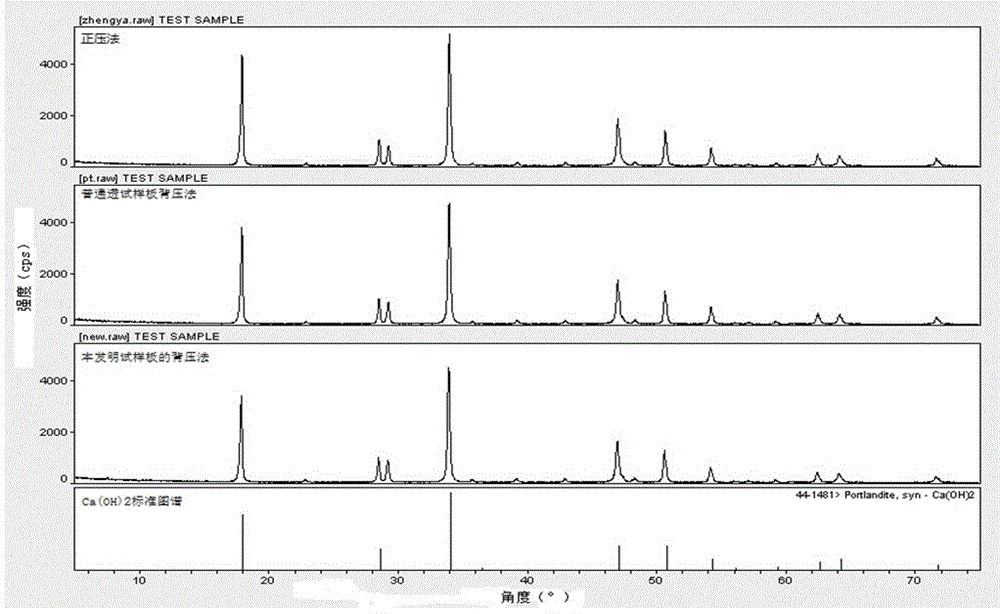

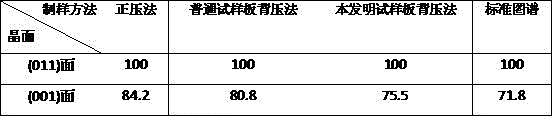

[0012] Embodiment 1: As shown in Figure 1, the device is composed of a permeable sample plate 2 and two object slides. The sample plate 2 has a sample hole, and its two sides are covered with magnetic substances, which can hold iron non-stick The two slides are firmly sucked on the sample plate 2; the first slide 1 and the second slide 3 are made of iron, and the surface is coated with anti-sticking substances after polishing to prevent the powder sample from sticking to the slide. When preparing the sample, suck the first slide 1 on the front of the sample plate 2, turn over the sample plate 2, put the powder sample in the sample hole, suck the second slide 3 on the back, and place the sample The sample plate 2 is righted up, and the first slide 1 sucked on the front of the sample plate 2 is removed, and the test can be carried out. When adopting the sample preparation through the sample plate proposed by the present invention, auxiliary articles such as clips and adhesive ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com