Rapid vacuumizing system and control method and device thereof

A technology of a vacuum pumping system and control method, which is applied in pump control, pump device, liquid variable capacity machinery, etc., can solve the problems of complicated disassembly and transportation, affecting production, time-consuming and laborious, etc. The effect of vacuuming efficiency and easy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that if there is a directional indication (such as above, lower, left, right, post, after, after, after, after, after ...), the directional indication is only used to interpret a particular attitude (such as the figures. Sign) The relative positional relationship between the components, the movement condition, etc., if the specific posture changes, the directional indication is also correspondingly changed.

[0038]Further, in the embodiment of the present invention relates to a "first", "second", the description, "first", "second", and the like are used only for the purpose of description, and cannot be understood as an indication or implied Its relative importance or implicit indicates the number of technical features indicated.

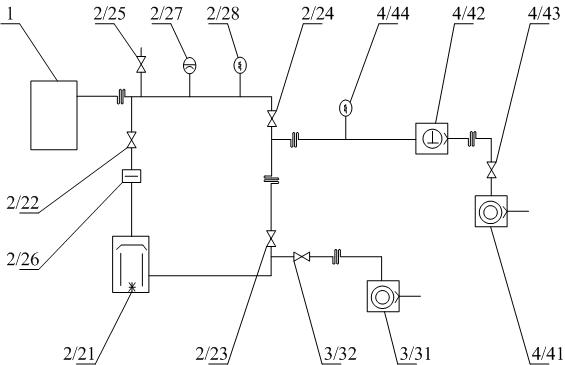

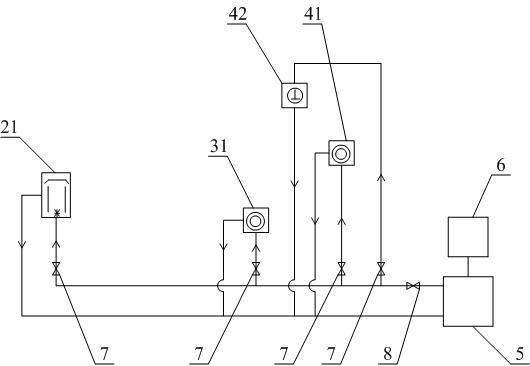

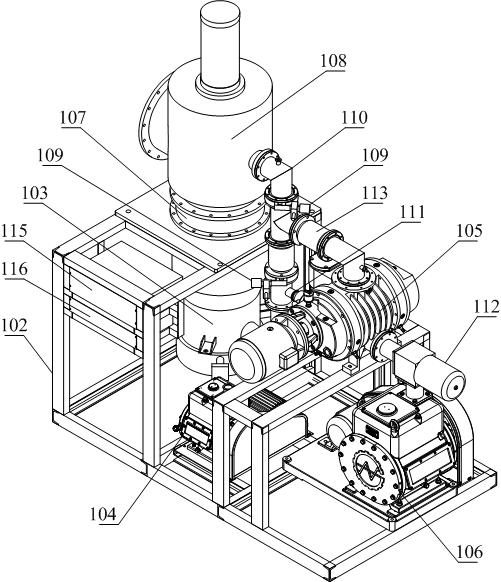

[0039] The present invention proposes a rapid vacuum system, figure 1 and figure 2 An example of a rapid vacuum system proposed by the present invention.

[0040] See figure 1 The rapid vacuum system includes a vacuum pumping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com