Pphotovoltaic junction box simulation waterproof and dustproof grade testing device

A waterproof, dust-proof, and volt junction box technology, which is used in measuring devices, fluid tightness testing, and machine/structural component testing. It can solve problems such as inconvenient installation of photovoltaic junction boxes, complicated detection methods, and low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

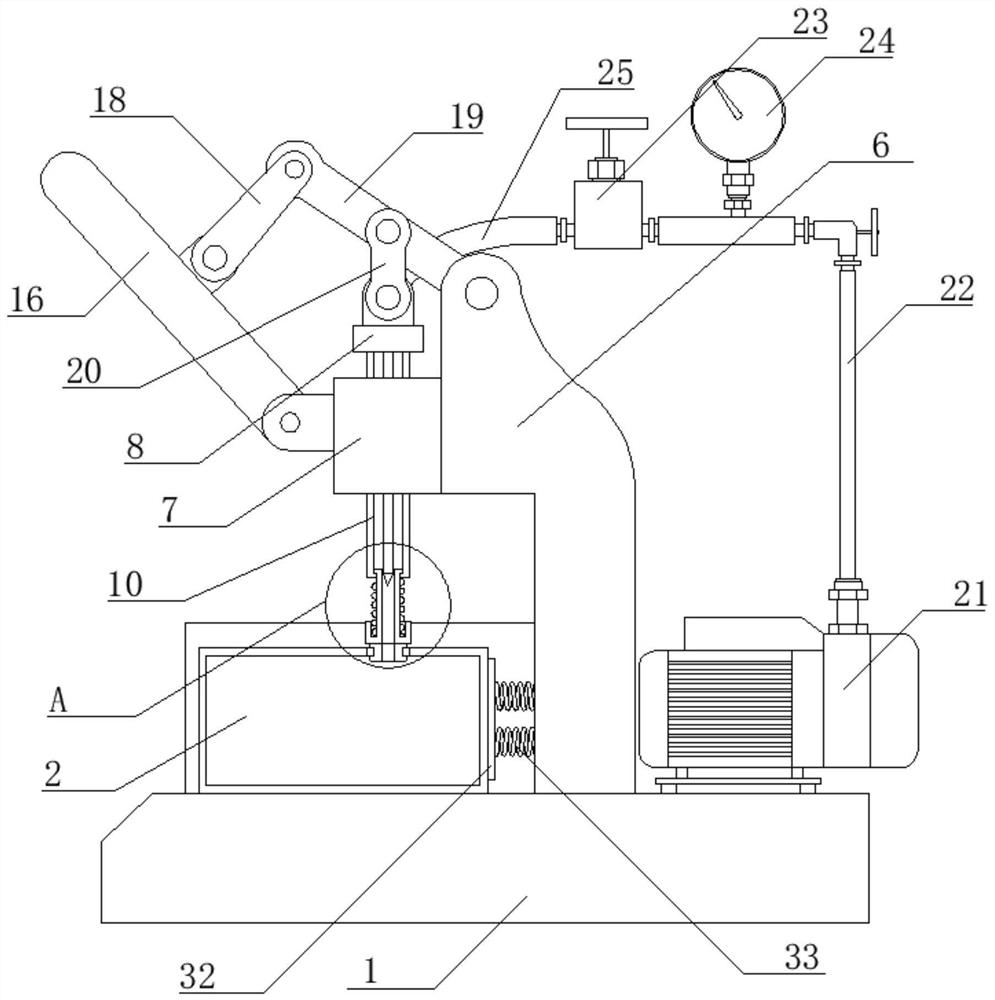

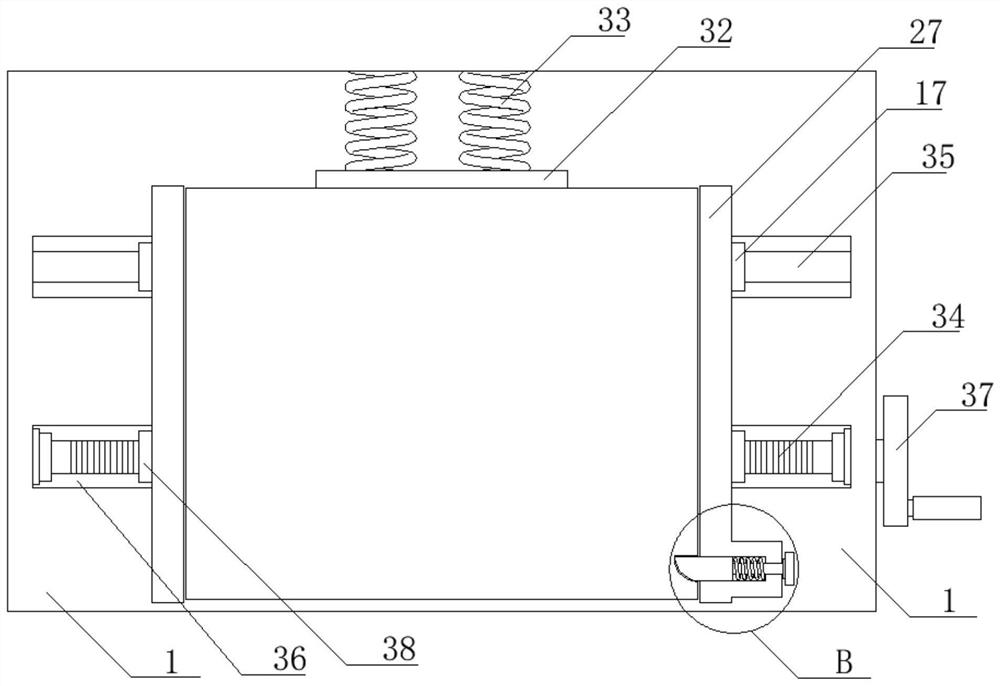

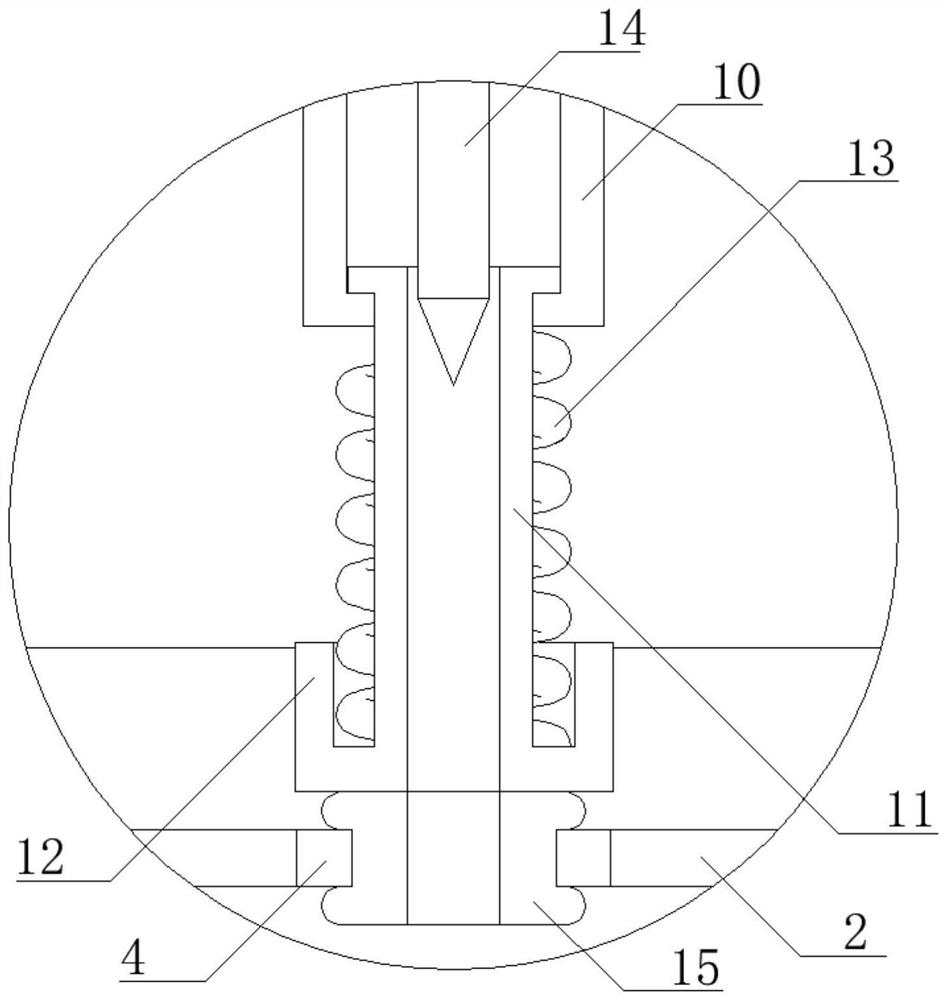

[0036] A photovoltaic junction box simulation waterproof and dustproof level test device, including a base 1 and a junction box 2, the top of the junction box 2 is provided with an air hole 3, the inside of the air hole 3 is fixedly connected with an elastic sealing ring 4, and the bottom end of the elastic sealing ring 4 The sealing layer 5 is fixedly connected, the upper end of the base 1 is fixedly connected with a bracket 6, the upper end of the bracket 6 is fixedly connected with a fixed sliding tube 7, and a telescopic connecting tube is slidingly connected in the fixed sliding tube 7, and the top end of the telescopic connecting tube passes through the connecting seat 8 A down-pressing mechanism is connected, and the down-pressing mechanism is connected with the bracket 6 and the fixed sliding cylinder 7. The upper end of the telescopic connecting cylinder is also connected with a vacuum assembly. The surface of the base 1 is provided with a screw adjustment assembly, whi...

Embodiment 2

[0042] A photovoltaic junction box simulates a waterproof and dustproof level test device, including the following operating methods:

[0043] Step 1, during the production process, process the air hole 3 and the fixing groove 9 on the junction box 2, and fix the elastic sealing ring 4 and the sealing layer 5 in the air hole 3;

[0044] Step 2, turn the rocker 37, the rocker 37 drives the two-way screw mandrel 34 to rotate, and the two-way screw mandrel 34 drives the two fixed plates 27 to close together through the two nut pairs 38, so that the distance between the two fixed plates 27 is the same as that of the junction box 2 Specifications match;

[0045] Step 3, when testing, push the junction box 2 between the two fixing plates 27 on the upper end of the base 1, when the fixing groove 9 enters the position of the fixing block 29, the compression spring 2 31 drives the fixing block 29 into the fixing groove 9 to connect the wires The box 2 is fixed, and the air hole 3 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com