A kind of heat-conducting two-component potting glue and preparation method thereof

A potting, two-component technology, used in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of insufficient weather resistance and poor compatibility of potting adhesives. To achieve the effect of convenient observation, low viscosity and good leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

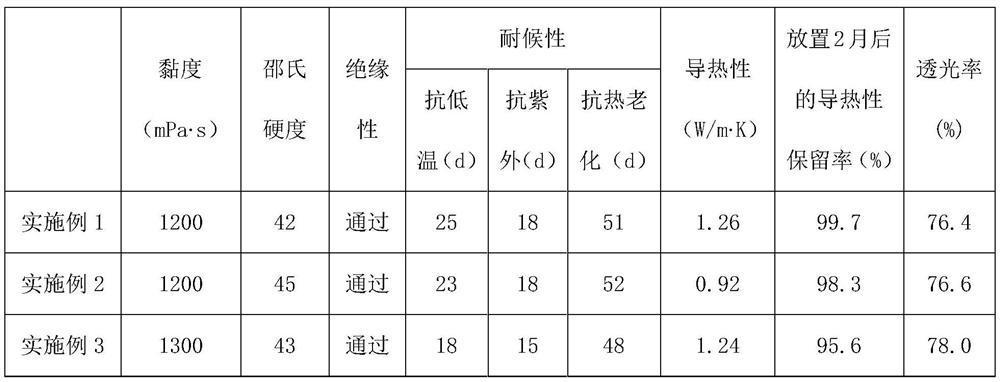

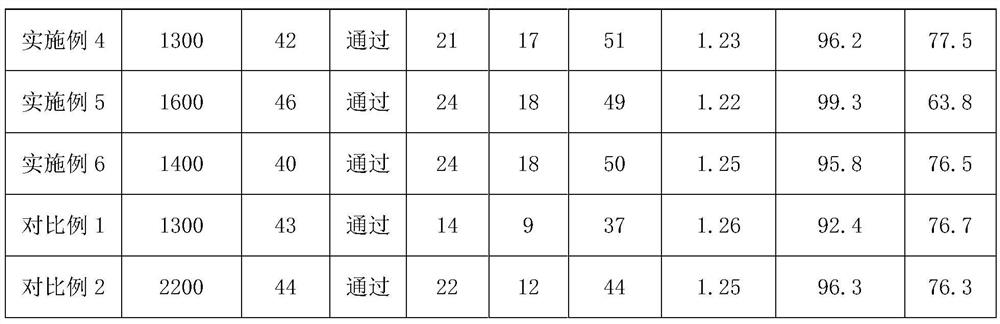

Examples

preparation example 1

[0037] Methacrylic acid, allyl polyoxyethylene ether and vinyl trimethoxysilane are fed in a molar ratio of 8:3:1, and toluene 2.3 times the total mass of the monomer is added as a solvent, and heated to 80°C under a nitrogen atmosphere to reflux. Add 0.5wt% BPO of the total mass of the monomers dropwise, complete the dropwise addition in half an hour, continue to reflux for 4h, cool, filter, and vacuum dry to obtain a macromolecular coupling agent, which is prepared by adding toluene to a 30wt% solution.

[0038] Take 10 parts of aluminum nitride, add 77 parts of the above 30wt% toluene solution of macromolecular coupling agent after drying, ultrasonically disperse for half an hour, heat at 80°C for 3 hours, cool, put into methanol, and wash the resulting precipitate with methanol Several times, after drying, grind in a ball mill until the D50 is 1.5 μm to obtain modified aluminum nitride.

preparation example 2

[0040] Other conditions and steps are the same as in Preparation Example 1, except that monomer allyl polyoxyethylene ether is not added.

preparation example 3

[0042] Other conditions and steps are the same as in Preparation Example 1, except that the monomer vinyltrimethoxysilane is not added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com