Hand-feeling optically-variable UV-curable coating as well as preparation method and application thereof

A technology for curing coatings and light-curing resins. It is used in polyester coatings, rosin coatings, polyurea/polyurethane coatings, etc. It can solve the problems of graininess and uneven surface of the coating film, achieve smooth surface, protect the environment, and reduce VOC. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] On the other hand, the embodiment of the present application provides a method for preparing the hand-sensitive optically variable UV curable coating, comprising the following steps:

[0090] S01, prepare raw materials according to the components and contents contained in the hand-sensitive light-changing UV curable coating described in the above embodiments;

[0091] S02, mixing the amorphous polyester resin, the inorganic black pigment and the first organic co-solvent to configure the PU component;

[0092] S03, mix the second organic co-solvent and photoinitiator until the photoinitiator is dissolved, then add self-extinction photocurable resin, acrylic modified rosin resin, UV monofunctional monomer, UV multifunctional monomer, inorganic light-changing powder Mix with additives to configure UV components;

[0093] S04, respectively packing the PU component and the UV component to obtain a hand-sensitive light-changing UV curable coating.

[0094] Specifically, in ...

Embodiment 1

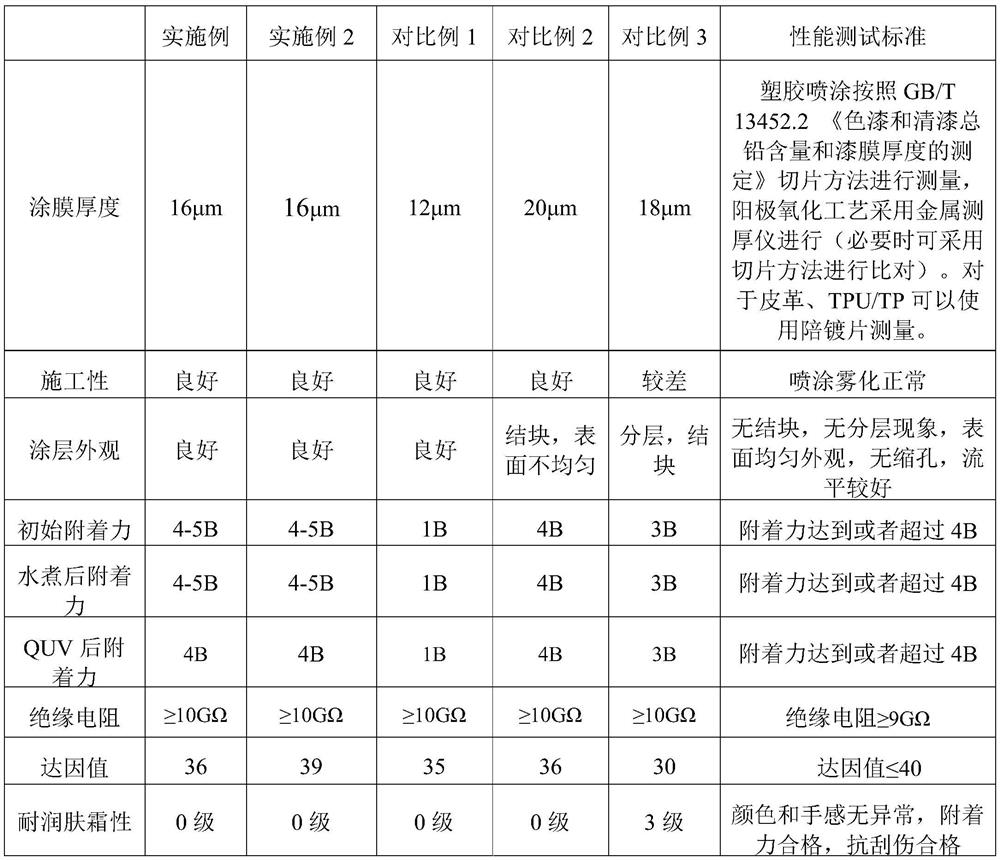

[0105] In above-mentioned embodiment 1, embodiment 2, comparative example:

[0106] The preparation method of described PU component:

[0107] After mixing butanone and cyclohexanone evenly, heat at 80°C for 20 minutes, then add amorphous polyester resin, and disperse for 10 minutes at a speed of 1500-2000 r / min.

[0108] The preparation method of the UV component:

[0109] The rotation speed of the above UV formula is 500-1000 rpm. After mixing the butanediisobutyl ketone and propylene glycol methyl ether evenly, add TPO to completely dissolve the TPO, and add the rest of the UV components. Disperse at rotational speed for 10 minutes.

[0110] Filter the PU component and UV component prepared in the above-mentioned Example 1, Example 2, and Comparative Example with a 300-mesh screen, spray the PU component onto the surface of the substrate, and bake it at 80°C for 30 minutes to control the film thickness. At 10~12μm; then spray UV components, bake at 65°C for 10min, and th...

Embodiment 2

[0124] Example 2 Compared with Example 1, Example 2 added melamine to the PU component, and the moisturizing cream resistance performance of Example 1 and Example 2 was 0 grade, and the moisturizing cream resistance performance was excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com