Electrode material with RuO2-IrO2 intermediate layer and for acidic wastewater treatment, and preparation method thereof

An acid wastewater, intermediate layer technology, applied in water/sewage treatment, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problem of low ammonia nitrogen degradation efficiency, poor stability, easy electrode Erosion and other problems occur, to achieve the effect of increasing active sites, improving corrosion resistance, and improving electrolytic oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

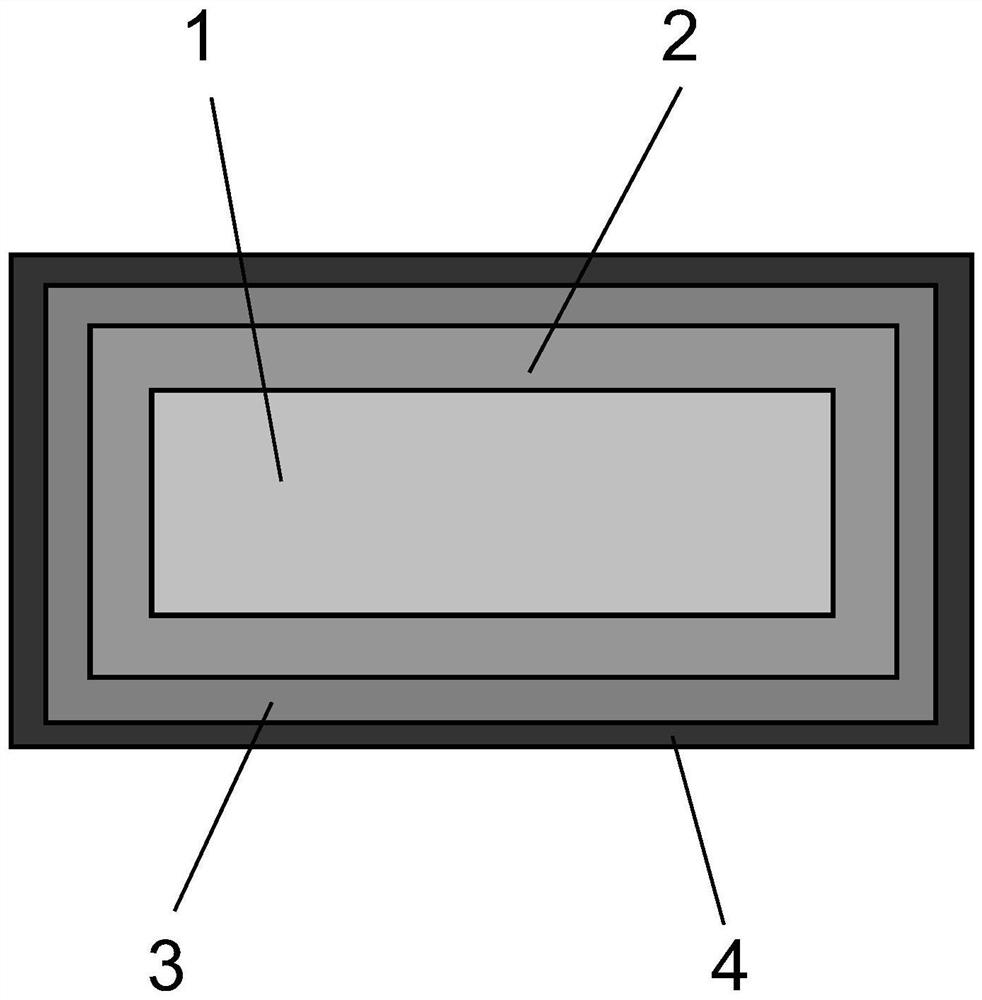

[0048] A kind of (Ti / RuO 2 -IrO 2 / PbO 2 ) / TiN composite electrode material and preparation method, including the following processes:

[0049] 1) Ti mesh substrate pretreatment:

[0050] The titanium mesh was placed in an acetone solution for ultrasonic treatment for 20 minutes, dried and placed in a 10% oxalic acid solution, etched in a slightly boiling water bath for 3 hours, washed, and vacuum-dried to form a Ti substrate. The Ti substrate was sealed in ethanol solution for standby; it was activated in 10mol / L NaOH solution for 5min before use.

[0051] 2) Preparation of Ti / RuO by pyrolysis 2 -IrO 2 :

[0052] (a) Precursor sol preparation

[0053] RuCl 3 ·xH 2 O and H 2 IrCl 6H 2 O Weigh the sample according to the molar ratio of 1:0.5, and disperse it in isopropanol to form a mixed solution, then heat the mixed solution in a water bath at 80°C, and slowly add 0.1mol / L HCl solution dropwise, A homogeneous sol was formed after 2 h.

[0054] (b) After immersing...

Embodiment 2

[0064] A kind of (Ti / RuO 2 -IrO 2 / PbO 2 ) / TiN composite electrode material and preparation method thereof, comprising the following process steps:

[0065] 1) Ti mesh substrate pretreatment:

[0066] Put the titanium mesh in acetone solution for 20 minutes, blow it dry, put it in 10% oxalic acid solution, etch it in a slightly boiling water bath for 3 hours, wash it, dry it in vacuum, and seal it in ethanol solution for later use; before use, put it in 10mol / L Activation in NaOH solution for 5min.

[0067] 2) Preparation of Ti / RuO by pyrolysis 2 -IrO 2 :

[0068] (a) Precursor sol preparation

[0069] RuCl 3 ·xH 2 O and H 2 IrCl 6H 2 O Weigh the sample according to the molar ratio of 1:0.3, and disperse it in isopropanol to form a mixed solution, then heat the mixed solution in a water bath at 80°C, and slowly add 0.1mol / L HCl solution dropwise, A homogeneous sol was formed after 2 h.

[0070] (b) After immersing the Ti substrate in the above sol for 15s, dry it, s...

Embodiment 3

[0078] A kind of (Ti / RuO 2 -IrO 2 / PbO 2 ) / TiN composite electrode material and preparation method thereof, comprising the following process steps:

[0079] 1) Ti mesh substrate pretreatment:

[0080] Put the titanium mesh in acetone solution for 20 minutes, blow it dry, put it in 10% oxalic acid solution, etch it in a slightly boiling water bath for 3 hours, wash it, dry it in vacuum, and seal it in ethanol solution for later use; before use, put it in 10mol / L Activation in NaOH solution for 5min.

[0081] 2) Ti / RuO prepared by thermal cracking method 2 -IrO 2 :

[0082] (a) Precursor sol preparation

[0083] RuCl 3 ·xH 2 O and H 2 IrCl 6H 2 O Weigh the sample according to the molar ratio of 1:0.25, and disperse it in isopropanol to form a mixed solution, then heat the mixed solution in a water bath at 80°C, and slowly add 0.1mol / L HCl solution dropwise, A homogeneous sol was formed after 2 h.

[0084] (b) After immersing the Ti substrate in the above sol for 15s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com