Electrode material based on polyimide mesocarbon microbead structure and preparation method thereof

A mesophase carbon microsphere and polyimide technology, which is applied in the preparation/purification of carbon, negative electrodes, battery electrodes, etc., can solve the problem of unstable structure of negative electrode materials, unfavorable high-rate charge and discharge, and influence on commercialization process, etc. problems, to achieve the effect of interlayer lithium intercalation and microporous lithium storage, excellent structural stability, and conducive to industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

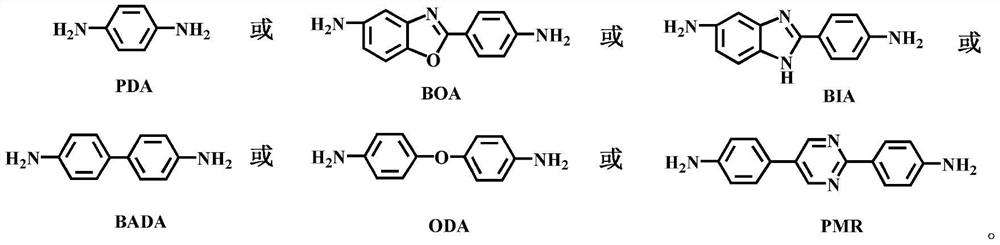

[0034] (1) Under the protection of nitrogen, add 100ml of NMP solvent to a 250ml three-necked flask, add 2.1628g of diamine monomer PDA and stir for 30min, after the diamine monomer is completely dissolved in the solvent, place the reaction system in an ice water bath Under the conditions, 6.4446g of dianhydride monomer BTDA was added and reacted with high-speed stirring for 8h to obtain a yellow-brown PAA solution.

[0035] (2) Place 100ml of the PAA solution obtained in step (1) in a 200ml autoclave, drop 1ml of isoquinolinone, and heat to 120°C for 1.5h, 170°C for 8h, then cool naturally To normal temperature, a heterogeneous PI-NMP suspension was obtained; the suspension was added to 100ml of NMP, sonicated for 15min, filtered with a sand core funnel, washed with ethanol, and dried under vacuum at 100℃ for 8h to obtain a yellow-brown polyimide powder ( PI).

[0036] (3) In a nitrogen atmosphere, heat up to 100°C at a heating rate of 3°C / min for 0.5~1h, 200°C for 1h, 300°C for ...

Embodiment 2

[0040] (1) Under the protection of nitrogen, add 120ml of DMF solvent into a 250ml three-necked flask, add 4.4822g of diamine monomer BIA and stir for 30min, after the diamine monomer is completely dissolved in the solvent, place the reaction system in an ice-water bath. Then, 6.2002g of dianhydride monomer ODPA was added, and the reaction was stirred at high speed for 8 hours to obtain a yellow-brown PAA solution.

[0041] (2) Place 80ml of the PAA solution obtained in step (1) into a 250ml autoclave, drop 1.5ml of isoquinolinone, heat up to 120℃ for 2h, 160℃ for 12h, then cool naturally To normal temperature, a heterogeneous PI-DMF suspension was obtained; the suspension was added to 120ml DMF, sonicated for 15 minutes, filtered with a sand core funnel, washed with ethanol, and dried in vacuum at 100°C for 8 hours to obtain a yellow-brown polyimide powder ( PI).

[0042] (3) In a nitrogen atmosphere, heat up to 100°C for 0.5h at a heating rate of 3°C / min, sinter at 200°C for 0.5...

Embodiment 3

[0046] (1) Under the protection of nitrogen, add 90ml of DMAc solvent to a 250ml three-necked flask, add 5.2424g of diamine monomer PMR and stir for 30min. After the diamine monomer is completely dissolved in the solvent, place the reaction system in an ice water bath Under conditions, 5.8844 g of dianhydride monomer BPDA was added, and the reaction was stirred at high speed for 12 hours to obtain a yellow-brown PAA solution.

[0047] (2) Place 90ml of the PAA solution obtained in step (1) into a 250ml autoclave, drop 1ml of isoquinolinone, heat up to 120°C for 2h, 160°C for 12h, and then cool to At room temperature, a heterogeneous PI-DMAc suspension was obtained; the suspension was added to 120ml DMAc, ultrasonicated for 20 minutes, filtered with a sand core funnel, washed with ethanol, and dried in vacuum at 100°C for 8 hours to obtain a yellow-brown polyimide powder (PI ).

[0048] (3) In a nitrogen atmosphere, heat up to 100°C at a heating rate of 3°C / min and sinter for 1 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com