Assembling and welding mould for thin-wall rectangular beam and using method thereof

A technology of rectangular beams and moulds, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve fast welding, save welding positioning, and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

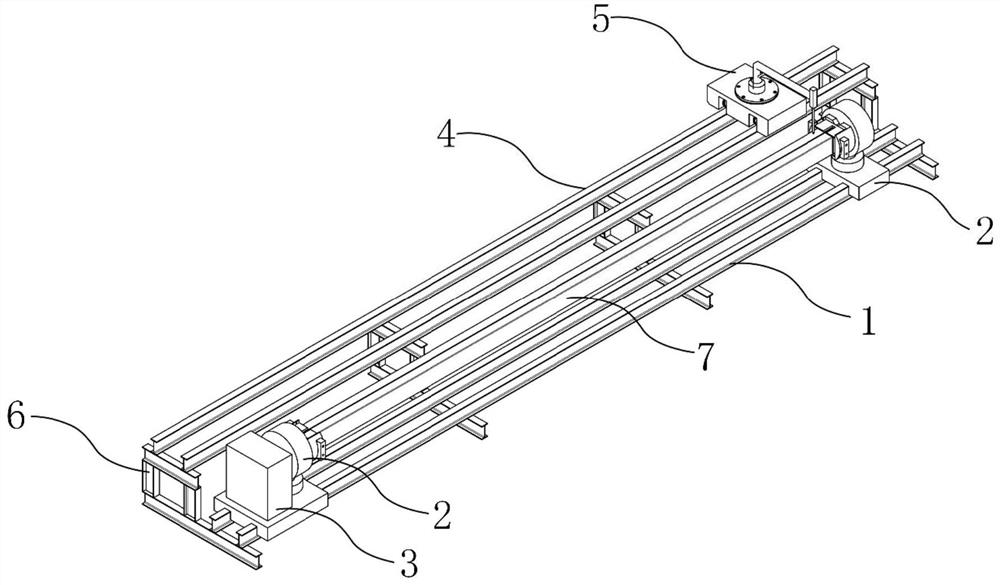

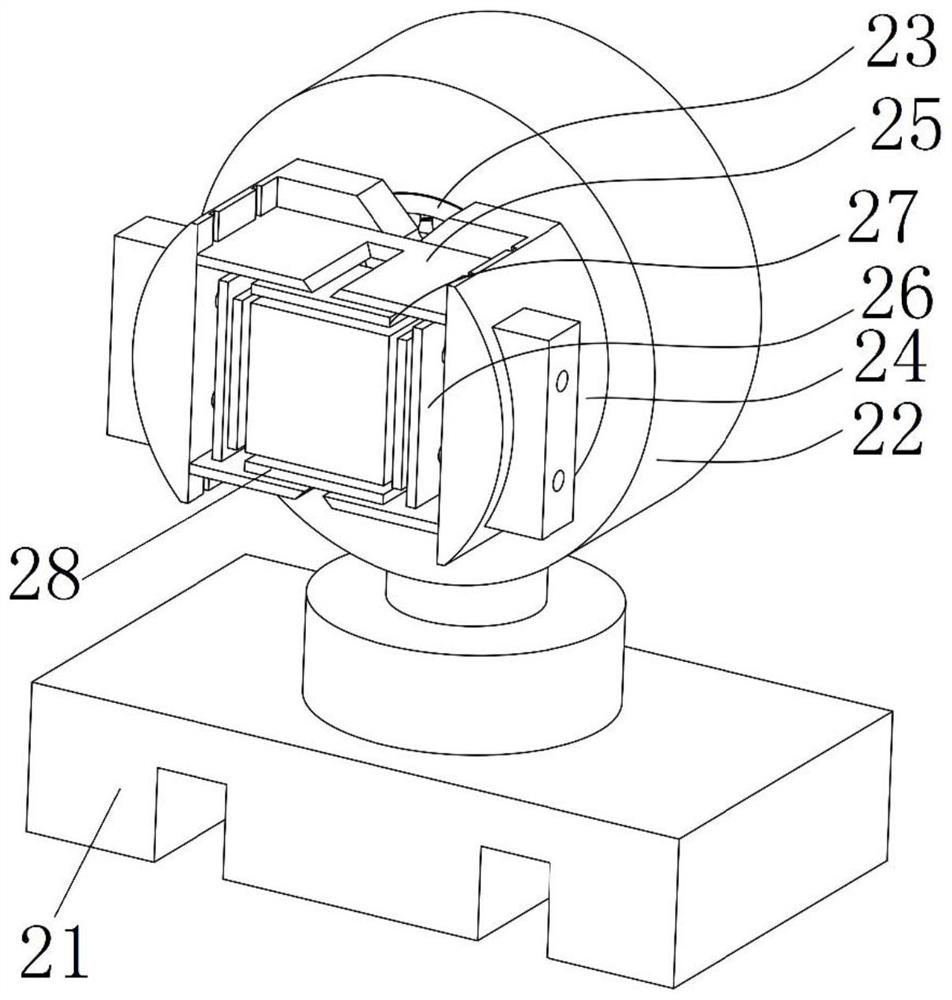

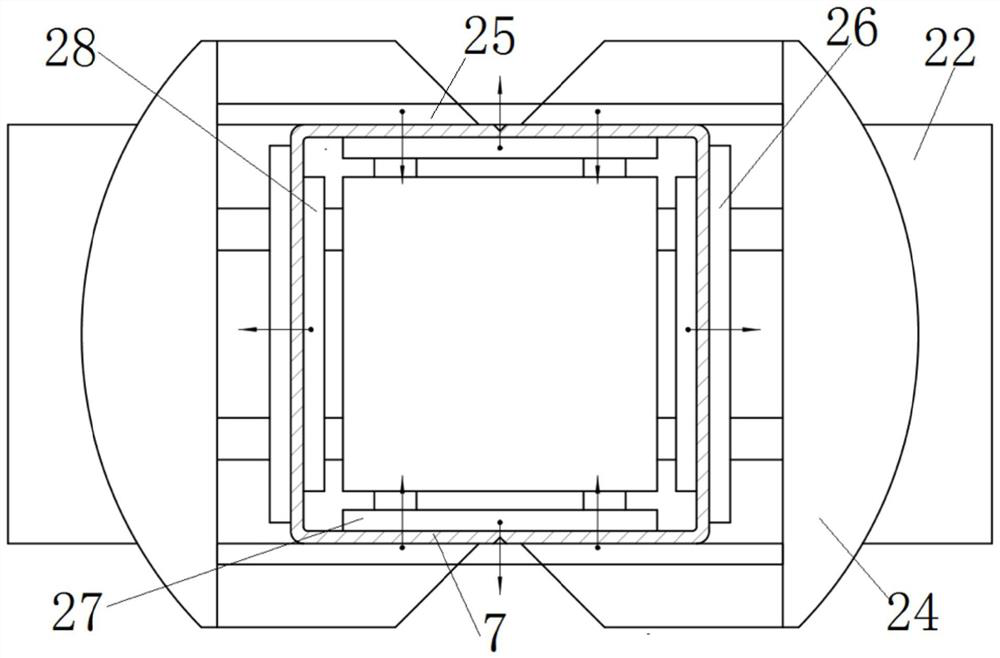

[0052] Embodiment 1 provides a thin-walled rectangular beam assembly welding mold, including automatic welding machine, welding machine guide rail, frame, chuck, chuck guide rail and power mechanism;

[0053] Install the welding machine guide rail and chuck guide rail horizontally on the frame, the automatic welding machine is installed on the welding machine guide rail, and the automatic welding machine can move horizontally along the welding machine guide rail; the chuck is installed on the chuck guide rail, and the workpiece to be welded It is clamped by the chuck; the power mechanism is set on one of the chucks, and the drive motor in the power mechanism is connected to the rotating bearing in the chuck through the transmission shaft. When the drive motor outputs power through the transmission shaft to rotate the bearing, the drive splint The rotation of the bracket, and then the workpiece to be welded rotates around its own axis, so as to realize the smooth turning of the ...

Embodiment 2

[0066] The difference from the above-mentioned embodiment 1 is that the power mechanism can also be removed, and the motor is installed on the chuck bracket to drive the workpiece to rotate around its own axis; the motor adopts a stepping motor or a synchronous motor.

Embodiment 3

[0068] The difference from the above-mentioned embodiment 1 is that when the workpiece to be welded has other shapes, the chuck can be replaced to change the shape of the inner splint and the outer splint to adapt to the shape of the workpiece to be welded at this time.

[0069] The assembled welding mold for thin-walled rectangular beams and the method of use thereof according to the present invention use the chuck to perform lateral positioning of the workpiece to be welded, so as to achieve rapid positioning; the inner splint and outer splint in the chuck realize the The workpiece to be welded is clamped, so that the welding parts of the workpiece to be welded can be quickly aligned, which is convenient for fast welding; by setting a power mechanism on the chuck bracket, the power mechanism drives the splint bracket to rotate, thereby realizing the smooth turning of the entire workpiece, avoiding the traditional When the welding method manually moves the workpiece, it will c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com