Moderately-thick aluminium alloy plate laser welding device and method

A laser welding, aluminum alloy technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of reducing the effect of removing pores and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

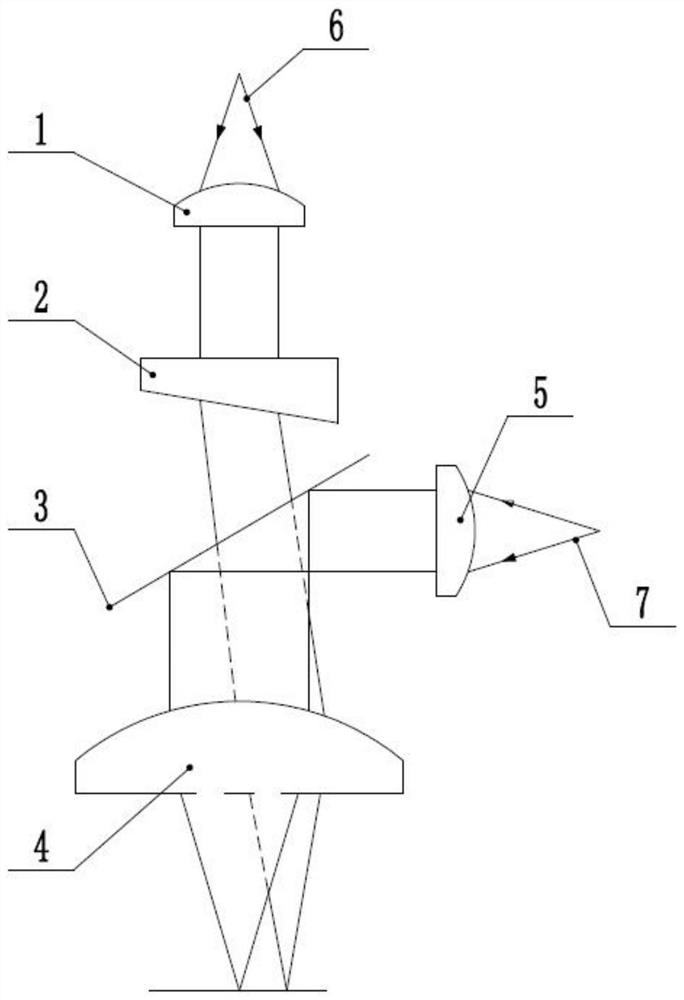

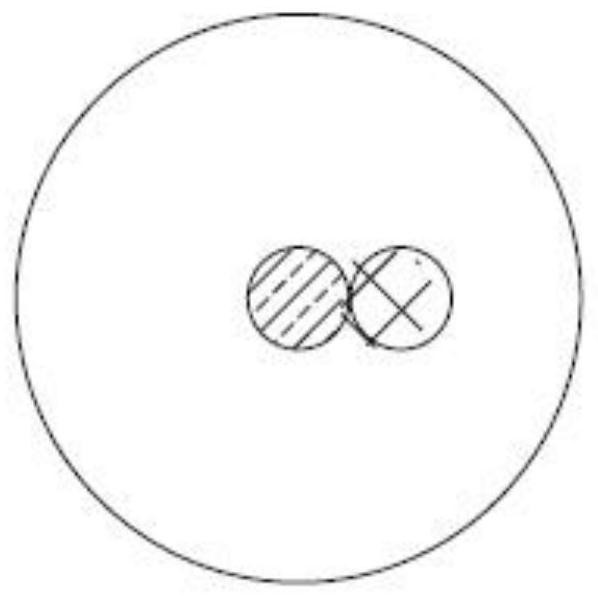

[0038] This embodiment provides a laser welding device for aluminum alloy medium and thick plates, such as Figure 1-Figure 8 As shown, including a first laser, a second laser, a first collimating mirror 1, a refracting mirror 2, a rotating platform, a reflecting mirror 3, a focusing mirror 4 and a second collimating mirror 5, both the first laser and the second laser can Move, the first laser can emit the first beam 6, the second laser can emit the second beam 7, the wavelength of the first beam 6 and the second beam 7 are different, the first collimating mirror 1 is facing the outgoing direction of the first beam 6 Set, the diameter of the first collimating mirror 1 is larger than the cross-sectional diameter of the first beam 6 cut off by the first collimating mirror 1, the first collimating mirror 1 can adjust the first beam 6 to a parallel beam, and the refracting mirror 2 is facing The first collimating mirror 1 is set, there is a gap between the refracting mirror 2 and ...

Embodiment 2

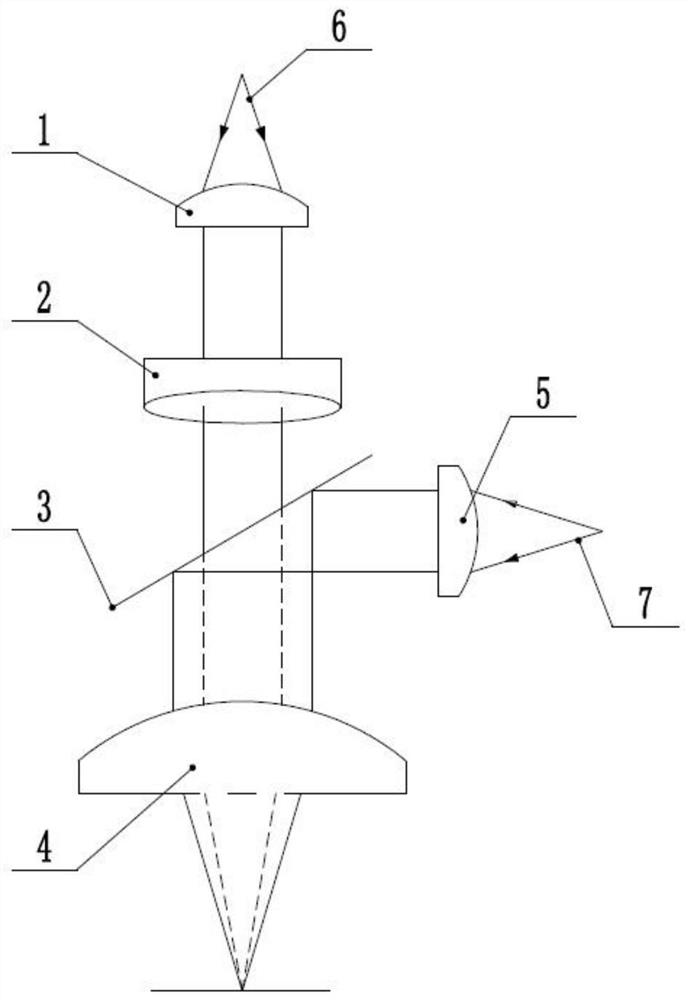

[0049] This embodiment is a further improvement made on the basis of Embodiment 1, as Figure 9 As shown, the present embodiment removes the refracting mirror on the basis of Embodiment 1; the center point of the reflecting mirror 3 is located on the axis of the focusing mirror 4, and the center line of the first collimating mirror 1 and the axis of the focusing mirror 4 have an eccentricity d, the eccentricity d ranges from 0 to 5 mm; the first collimating mirror 1 is connected with a rotating platform, and the rotating platform can drive the first collimating mirror 1 to rotate around the axis of the focusing mirror 4 with an eccentricity d.

[0050] Therefore, in the laser welding method for aluminum alloy medium and thick plates provided in this embodiment, the second beam 7 moves along the weld seam direction of the workpiece to be welded, and the focused second beam 7 moves along the weld seam direction of the workpiece to be welded At the same time, the rotating platfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com