Automatic turnover type plate surface spraying device

An automatic flipping and surface spraying technology, which is applied in spraying devices, liquid spraying devices, etc., can solve the problems that the plate cannot be turned over automatically and the degree of spraying automation is low, so as to achieve the effect of improving the automation function and improving the uniformity of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

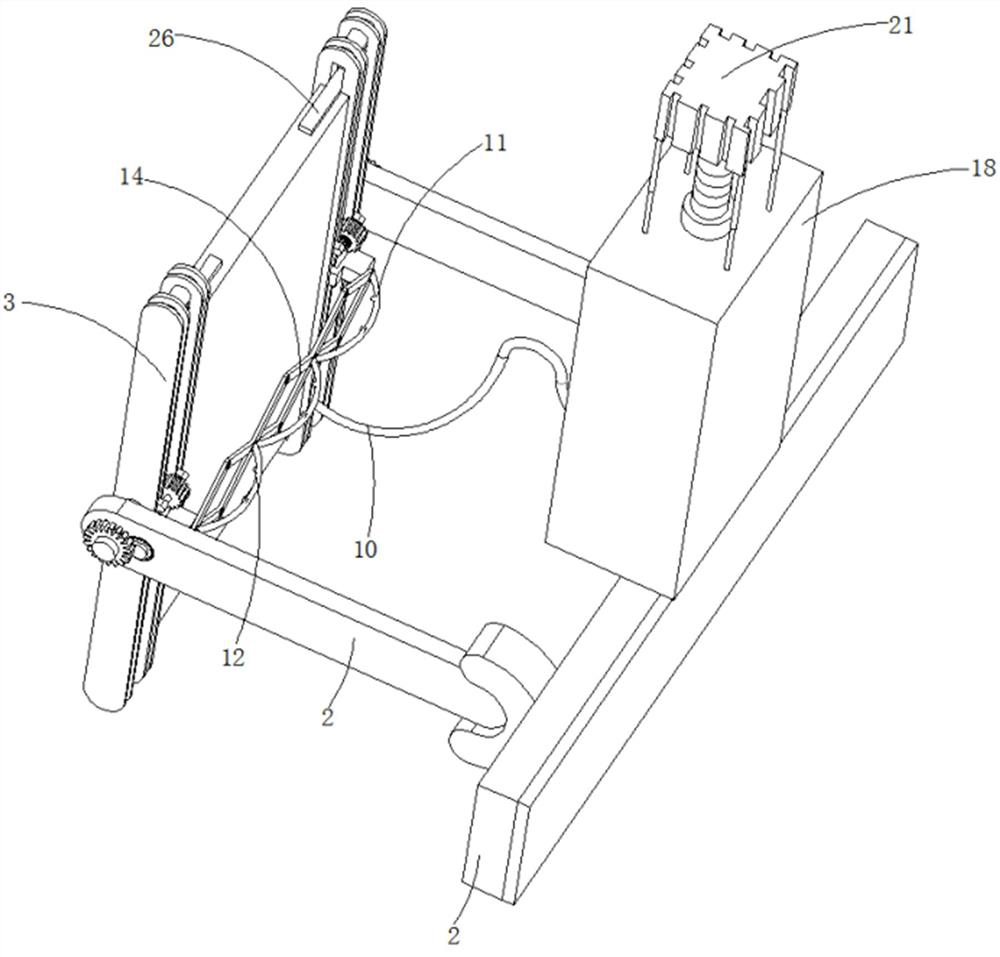

[0036] refer to Figure 1-8 , an automatic flip-type plate surface spraying device, including a mounting base 1, a symmetrically distributed support plate 2 is connected to the mounting base 1, a spraying assembly is arranged on the outside of the mounting base 1, and a liquid outlet pipe 10 is connected to the spraying end of the spraying assembly. , the opposite side of the support plate 2 is connected with the installation plate 3 through the rotation of the shaft, and one end of the shaft passing through the support plate 2 is connected with an intermittent rotation mechanism fixed on the support plate 2, and the installation plate 3 is provided with a The two tooth plates 4 are evenly and symmetrically distributed in the length direction, and the two tooth plates 4 have an arc transition. The mounting plate 3 is also provided with a chute 5 parallel to the tooth plate 4, and the chute 5 is slidably connected with an active slide. The block 6 and the driven slider 7, and t...

Embodiment 2

[0044] refer to Figure 1-8 , an automatic flip-type plate surface spraying device, including a mounting base 1, a symmetrically distributed support plate 2 is connected to the mounting base 1, a spraying assembly is arranged on the outside of the mounting base 1, and a liquid outlet pipe 10 is connected to the spraying end of the spraying assembly. , the opposite side of the support plate 2 is connected with the installation plate 3 through the rotation of the shaft, and one end of the shaft passing through the support plate 2 is connected with an intermittent rotation mechanism fixed on the support plate 2, and the installation plate 3 is provided with a The two tooth plates 4 are evenly and symmetrically distributed in the length direction, and the two tooth plates 4 have an arc transition. The mounting plate 3 is also provided with a chute 5 parallel to the tooth plate 4, and the chute 5 is slidably connected with an active slide. The block 6 and the driven slider 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com