A crop straw processing device

A technology of crop straw and processing device, applied in the field of crop processing, can solve the problems of low degree of automation, many power source parts, inconvenient operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

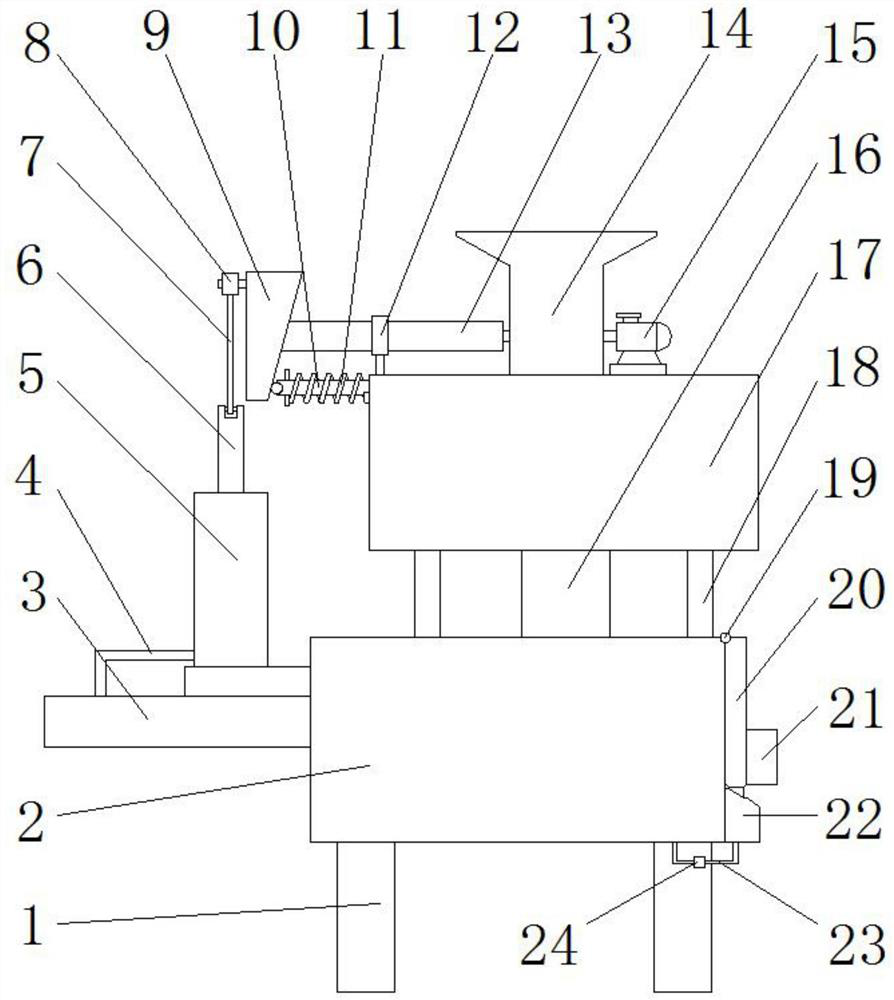

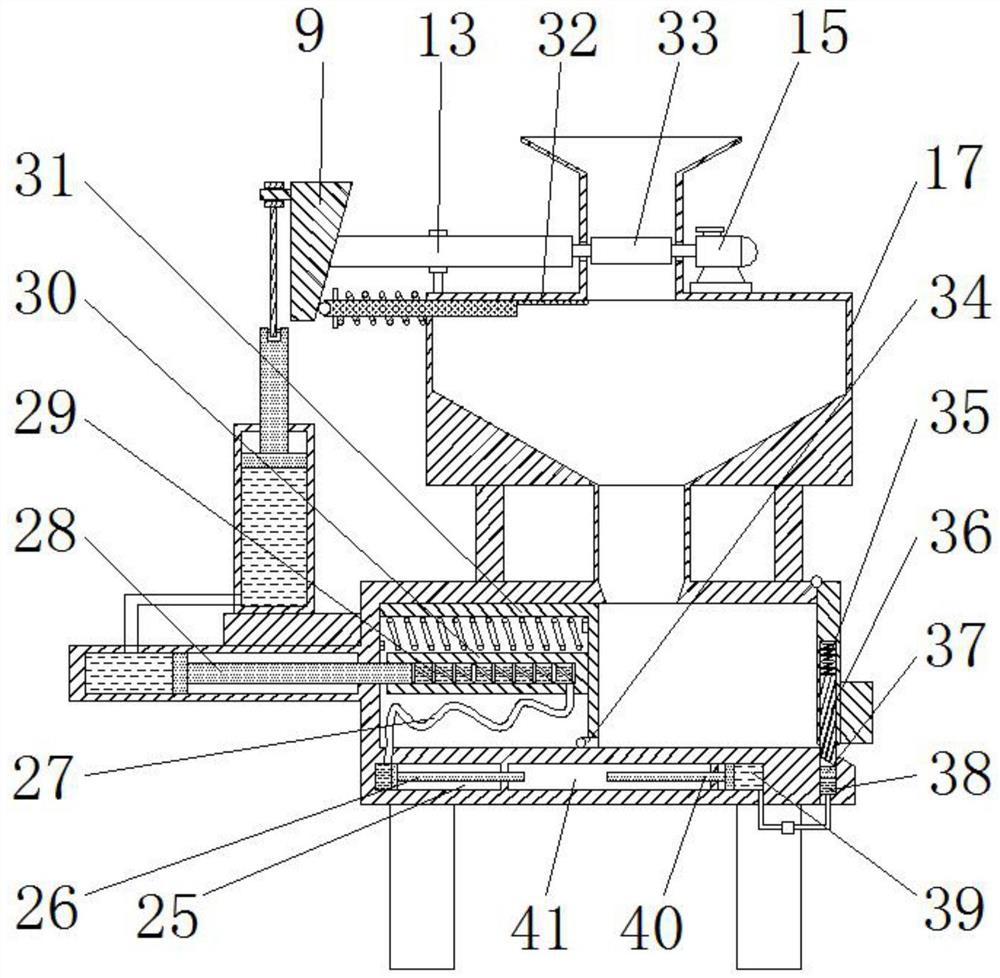

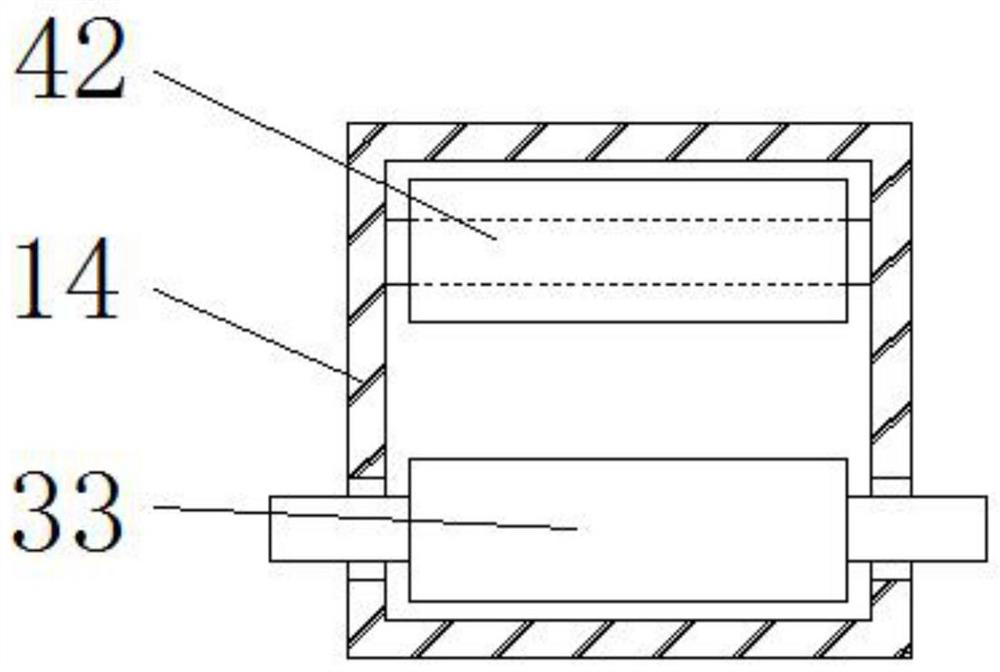

[0028] Such as figure 1 The shown crop stalk processing device includes a lower box 2 supported on the ground by a support leg 1 and an upper box 17 connected above the lower box 2 by a support rod 18, and the top of the upper box 17 is A feed pipe 14 is communicated on the surface, and a connecting pipe 16 arranged vertically is communicated between the bottom surface of the upper box 17 and the lower box 2, such as figure 2 As shown, one side at the position where the top surface of the upper box body 17 is connected to the feed pipe 14 is horizontally slidably connected with a telescopic rod 10, and the telescopic rod 10 is fixed with a horizontally arranged cutter 32; The body 2 is provided with an "L"-shaped extruded plate 31, and the lateral part of the extruded plate 31 is attached to the inner top surface of the lower box body 2, and the lower end of the longitudinal part of the extruded plate 31 is attached to the lower box body 2. The inner bottom surface of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com