Sensor measuring point optimization method for reducing strain field reconstruction error

A technology for reconstructing errors and optimization methods, applied in design optimization/simulation, special data processing applications, etc., can solve problems such as low accuracy of recognition results, and failure of interpolation methods to effectively use structural mechanical properties, etc., to achieve efficient solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

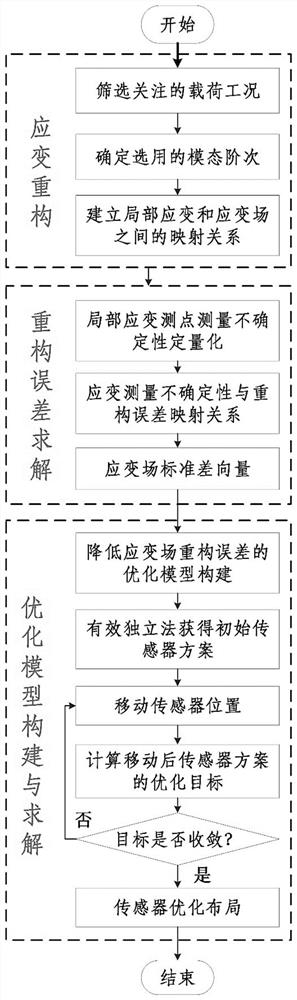

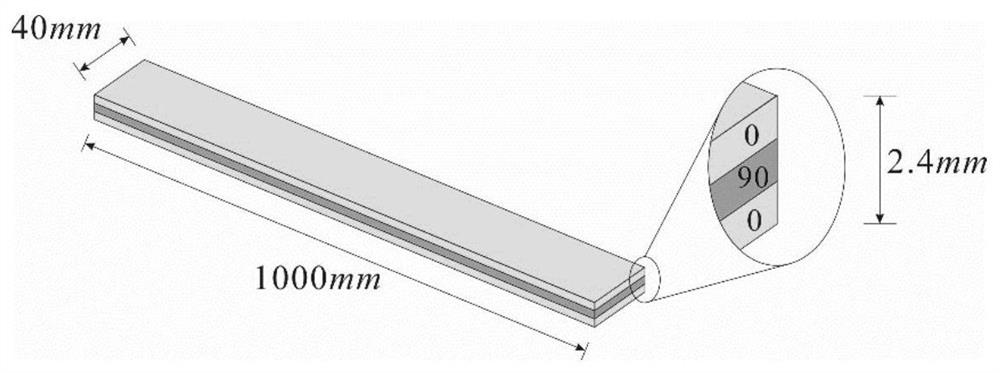

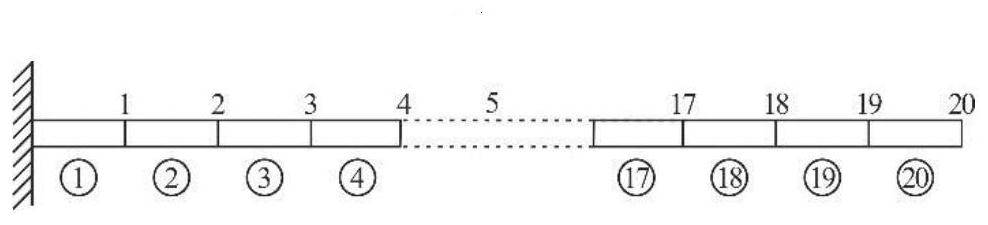

[0092] In order to fully understand the characteristics of the invention and its applicability to engineering practice, the invention optimizes the sensor arrangement for the strain field reconstruction of the composite cantilever beam structure. The composite material layup is as follows: figure 2 shown. The cantilever beam is subjected to three typical distributed load cases, and the unit and node numbers of the model are as follows: image 3 As shown, the loading conditions are as Figure 4 shown.

[0093] The composite material is made of carbon fiber fabric, and its material parameters are shown in Table 1.

[0094] Table 1 Composite material properties

[0095]

[0096] The established finite element model is solved for each order mode, and the strain mode shapes of each order are obtained. Then establish the following optimization model to optimize the strain sensor measuring points:

[0097]

[0098] In the formula Represents a sensor scheme, i represents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com