Improved hollow glass

An improved, hollow technology, applied in the installation of window glass, parallel glass structure, window/door, etc., can solve the problems of troublesome disassembly and replacement, non-adjustable interlayer thickness, and high cost of complete replacement, so as to improve flexibility performance, reduce maintenance costs, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

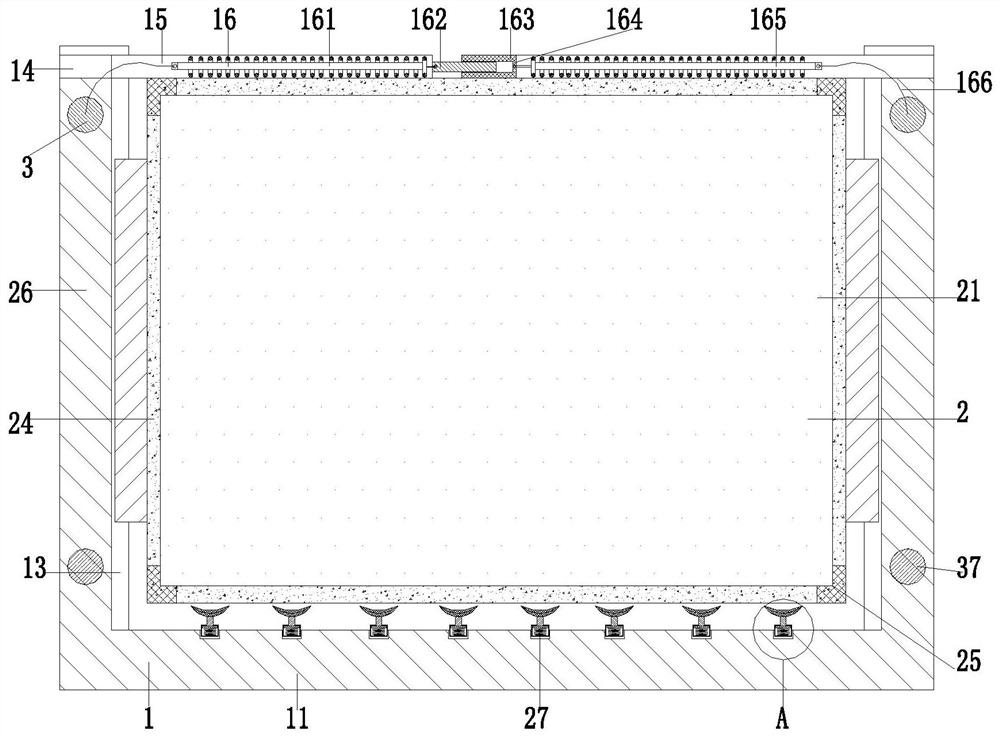

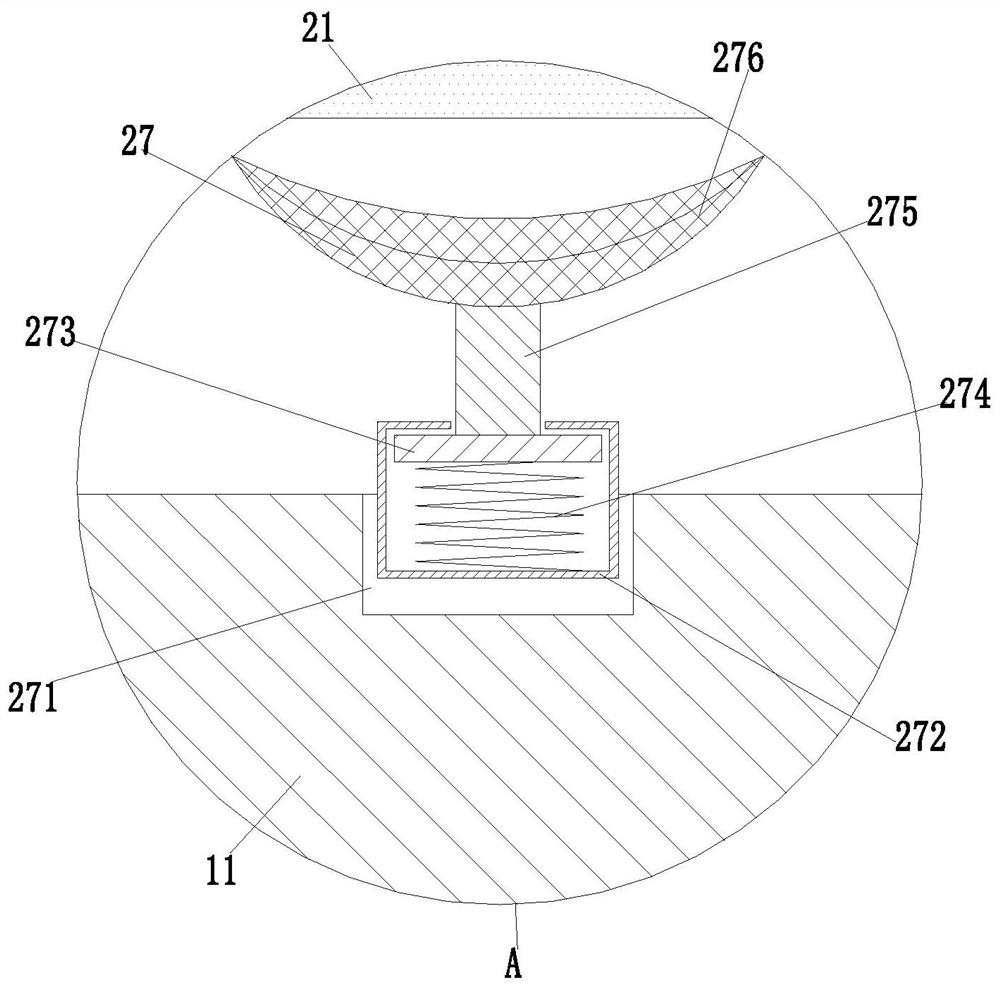

[0029] Such as Figure 1 to Figure 6 As shown, an improved insulating glass includes a window frame 1, an insulating glass 2 and an adjustment mechanism 3. The insulating glass 2 is installed in the window frame 1 through a sliding fit, and the left and right ends of the insulating glass 2 are symmetrically arranged. The adjustment mechanism 3 is installed on the left and right ends of the window frame 1 through screw fit.

[0030] The window frame 1 includes a front frame 11, a rear frame 12, a chute 13, a limit groove 14, a limit plate 15 and an opening and closing branch chain 16, and the front frame 11 and the rear frame 12 are provided with The U-shaped structure of the opening, and the front frame 11 and the rear frame 12 are symmetrical abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com