Efficient sedimentation tank used under mine

A high-efficiency sedimentation tank and underground mine technology, applied in sedimentation treatment, flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problems of high operating cost, large floor area, long process flow, etc., and achieve oxygen utilization The effect of high efficiency, reduced floor area and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

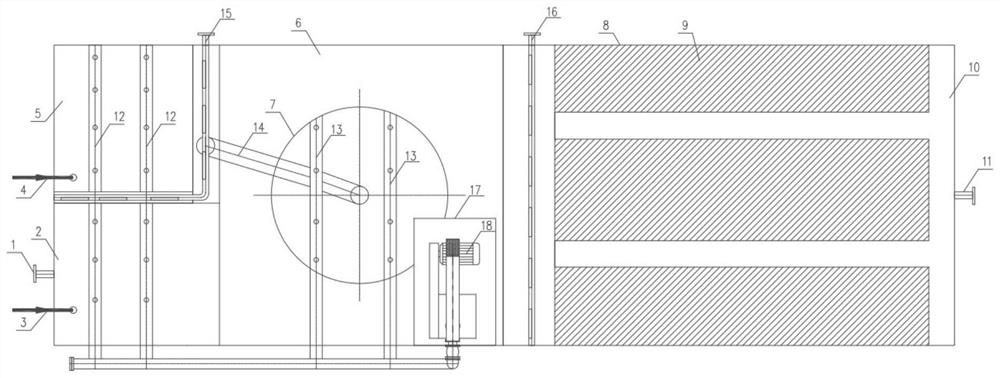

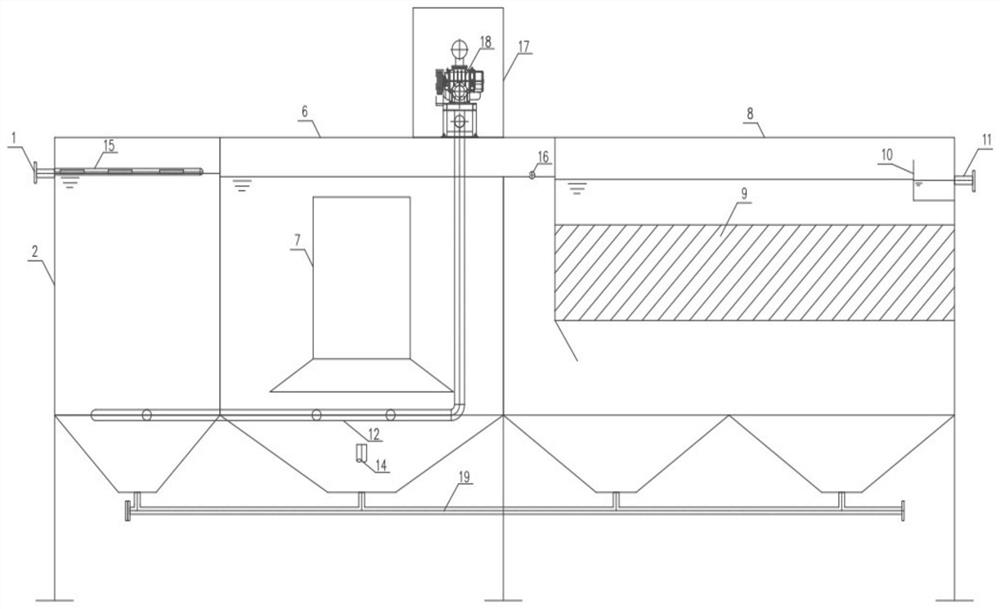

[0026] In order to illustrate the present invention more clearly, the following will briefly introduce the drawings used in the implementation cases or the description of the existing invention.

[0027] see figure 1 , is a preferred embodiment of a high-efficiency sedimentation tank for mines, which can treat iron-containing, turbid, and oil-containing wastewater in mines, including mixing area 2, reaction area 5, flocculation area 6, sedimentation area 8, and the second An aeration pipe 12 , a second aeration pipe 13 , an aeration fan 18 , a first oil slick collection pipe 15 , and a second oil slick collection pipe 16 . The details are as follows:

[0028] The mixing zone 2 mainly includes the water inlet 1, the coagulant dosing pipe 3, and the bottom sludge discharge pipe 19, which is mainly used for coagulant dosing and mixing, and the bottom sludge discharge pipe 19 can remove the sludge generated in the mixing zone.

[0029] The reaction zone 5 mainly includes a polya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com