Carton full-bottom printing device, and printing method

A printing device and carton technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of inconvenient carton flattening, cooling, inconvenient carton drying, etc., to improve the flattening effect and increase friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

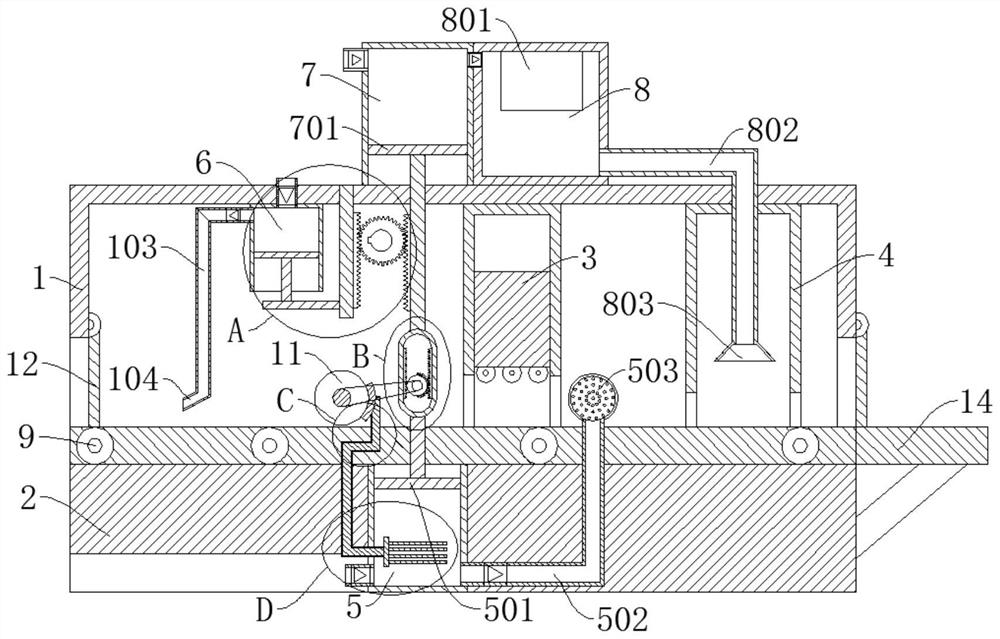

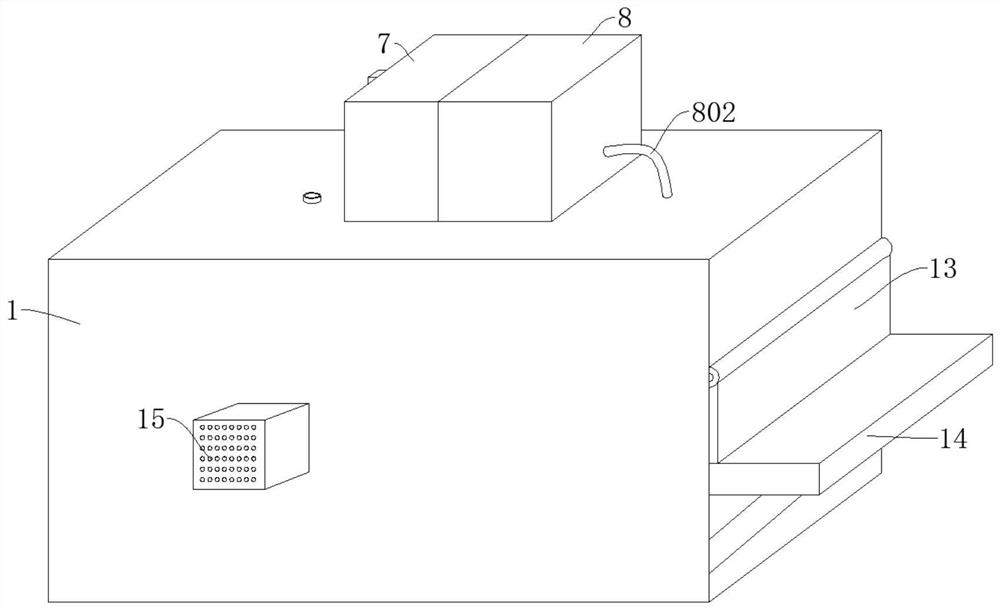

[0036] refer to Figure 1-6, a carton full-bottom printing device and printing method, including a box body 1, a base 2, and a printing room 3, the printing room 3 is located in the box body 1, the base 2 is fixed at the lower end of the box body 1, and the base 2 is provided with a conveyor belt 9 The side wall of the box body 1 is respectively provided with a feed port and a discharge port, and the side wall of the box body 1 close to the feed port is rotatably connected with a rolling roller 11, and the side wall of the box body 1 is provided with a drive motor 15, and the drive motor The output end of 15 is fixedly connected with the rolling roller 11, and the half-toothed rotating shaft 111 is connected in rotation in the box body 1, and a transmission belt is connected between the half-toothed rotating shaft 111 and the rolling roller 11, and a rack ring 112 is arranged in the box body 1. The rack ring 112 is meshed with the half-tooth shaft 111, the upper end of the rac...

Embodiment 2

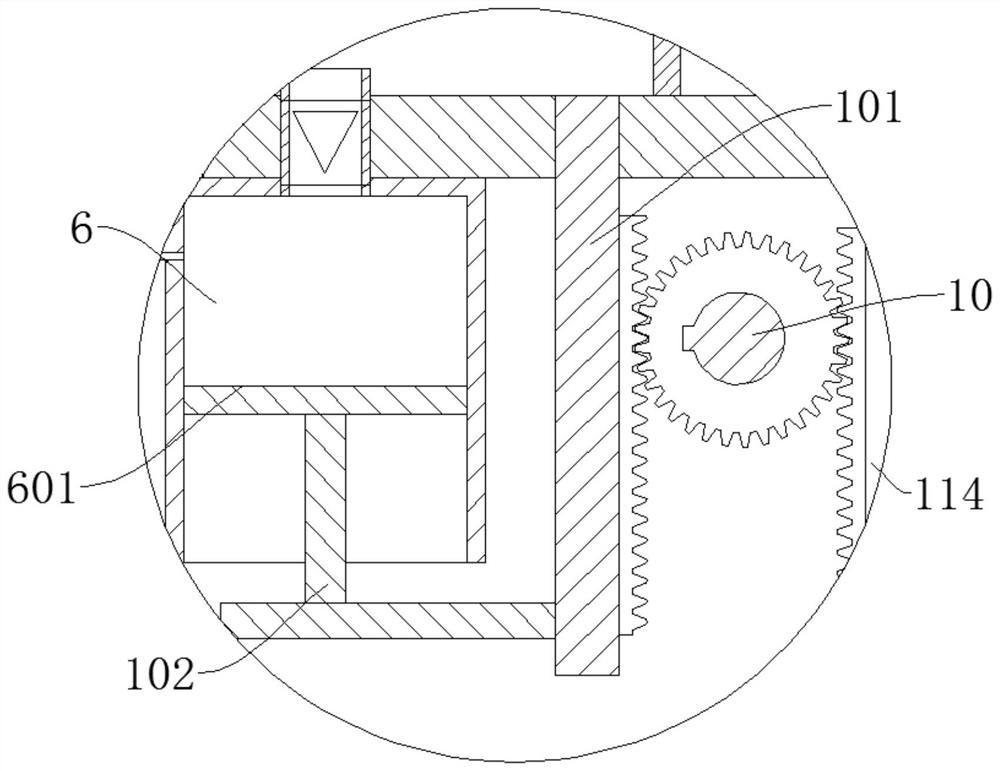

[0039] refer to Figure 1-6 , a carton full-bottom printing device and printing method are basically the same as in Embodiment 1, furthermore, a sliding rod 101 is slidably connected to the casing 1, and a gear 10 is connected to the casing 1 for rotation, and the second connecting rod 114 and the sliding rod 101 are meshed with the gear 10, the box body 1 is provided with a third cylinder 6, the third cylinder 6 is slidingly connected with a third piston 601, the lower end of the third piston 601 is fixedly connected with a push rod 102, and the push rod 102 is away from One end of the third piston 601 is fixedly connected with the slide rod 101, the third air cylinder 6 is provided with a third conduit 103, the third air cylinder 6 is provided with an air inlet, and the rack ring 112 drives the slide rod 101 to reciprocate up and down through the gear 10 , and then push the push rod 102 to push the third piston 601 to reciprocate up and down to pump and exhaust the third air...

Embodiment 3

[0041] refer to Figure 1-6 , a kind of carton full-bottom printing device and printing method are basically the same as embodiment 1, and further, the first nozzle 503, the second nozzle 803, and the third nozzle 104 are all aimed at the conveyor belt 9, and the drying, drying and printing methods are added respectively. Efficiency and effectiveness of cooling and cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com