A guiding mechanism and its cutting cable 3D printing device

A guiding mechanism and guiding technology, applied in manufacturing auxiliary devices, 3D object support structures, processing and manufacturing, etc., can solve the problems of stagnant cutting cable processing technology, insufficient cutting cable processing level, and inability to use special-shaped pipe processing methods, etc. Achieve the effect of fast filling, improving yield and continuous printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The cutting cable 3D printing process of the present embodiment comprises the following steps:

[0041] S1, the explosives are adjusted into fat. It is generally prepared by combining acetone, dimethyl sulfoxide and some mixed solvents with RDX. In this embodiment, the paraffin passivation of RDX can be adopted, and then the RDX can be dissolved with acetone and prepared into a viscous fat. At the same time, some kinetic agents can be added to adjust the detonation temperature. Generally, 1700A current short circuit is required to detonate the RDX after passivation by paraffin to detonate the sensitive agent, and then pass the sensitive agent to increase the temperature to detonate the RDX. Therefore, the detonation of RDX after paraffin passivation The temperature is at least several thousand degrees Celsius (the temperature of RDX is at least tens of thousands of degrees Celsius after detonation), and the temperature during 3D printing is controlled at about 200 degr...

Embodiment 2

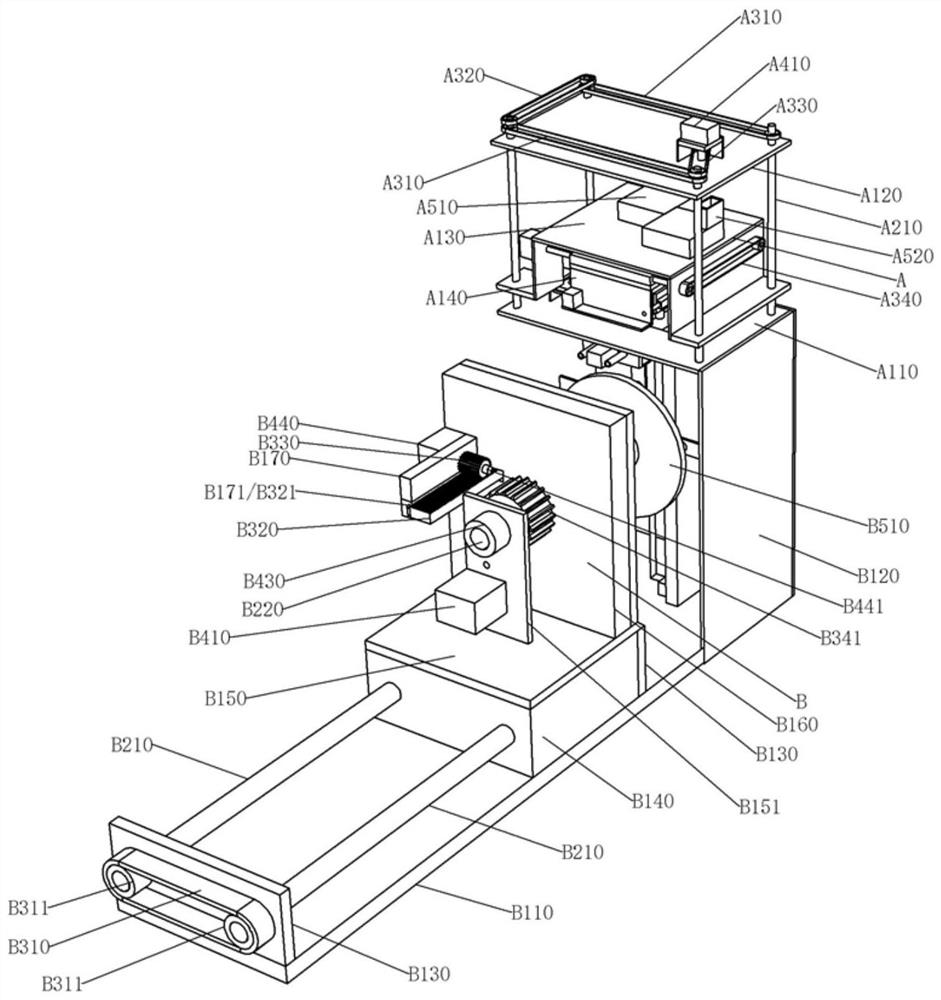

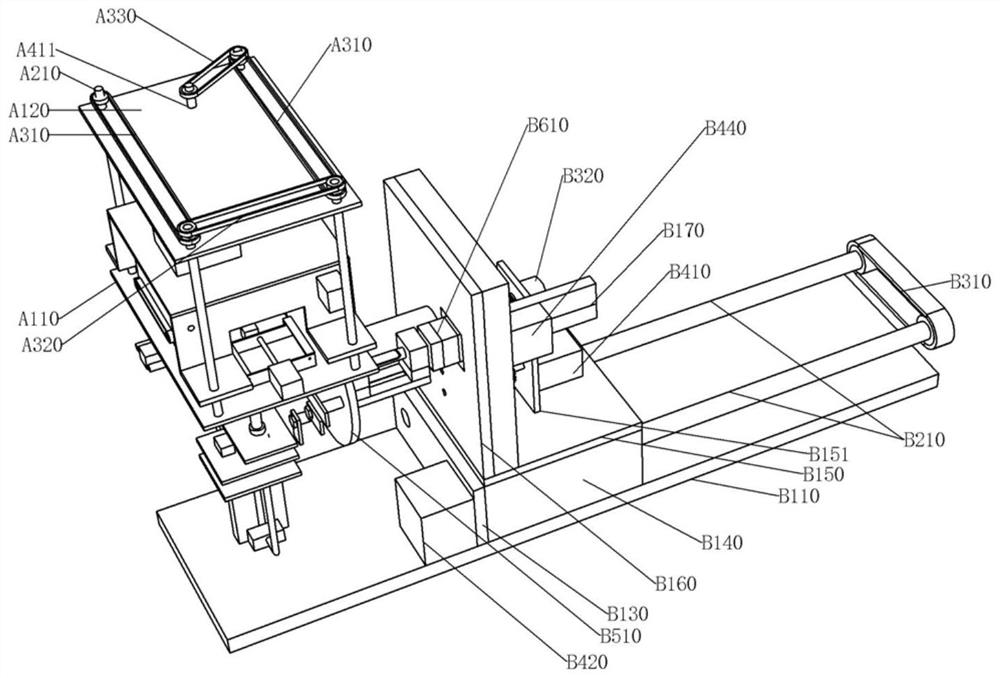

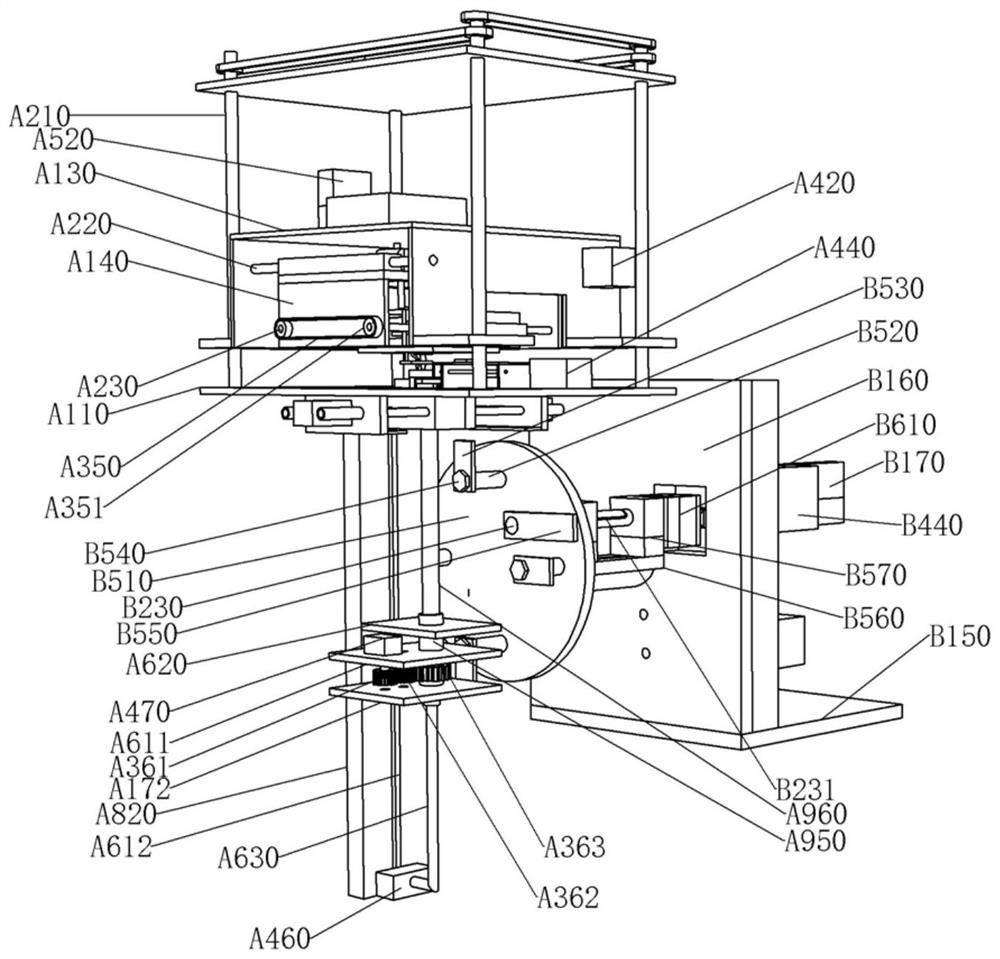

[0046] see Figure 1-Figure 27 , this embodiment is to realize the device for printing the inner tube in Embodiment 1, including:

[0047] The printing module A prints out the inner tube 100 with melted plastic as the raw material, and at the same time fills the inner cavity of the inner tube with a fat-like explosive 200;

[0048] The guide mechanism keeps the printed inner tube continuously extended in the axial direction to obtain a longer inner tube by continuously moving downwards, and at the same time ensures that the printing end of the inner tube and the printing module does not move to ensure printing accuracy.

[0049] The winding mechanism B is used for winding the printed inner tube 100, so as to realize the processing of a longer inner tube.

[0050] see Figure 1-Figure 13 , the printing module A includes a printing bottom plate A110 and a printing top plate A120, the printing bottom plate A110 and the printing top plate A120 are connected by at least four prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com