Zinc alloy slagging robot and working method

A zinc alloy and robot technology, used in metal processing equipment, manipulators, mechanical cleaning and other directions, can solve the problems of poor working environment, high labor intensity, and difficulty in improving the quality of artificial products, to ensure stability, improve the quality of slag removal, The effect of reducing cost and controlling difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

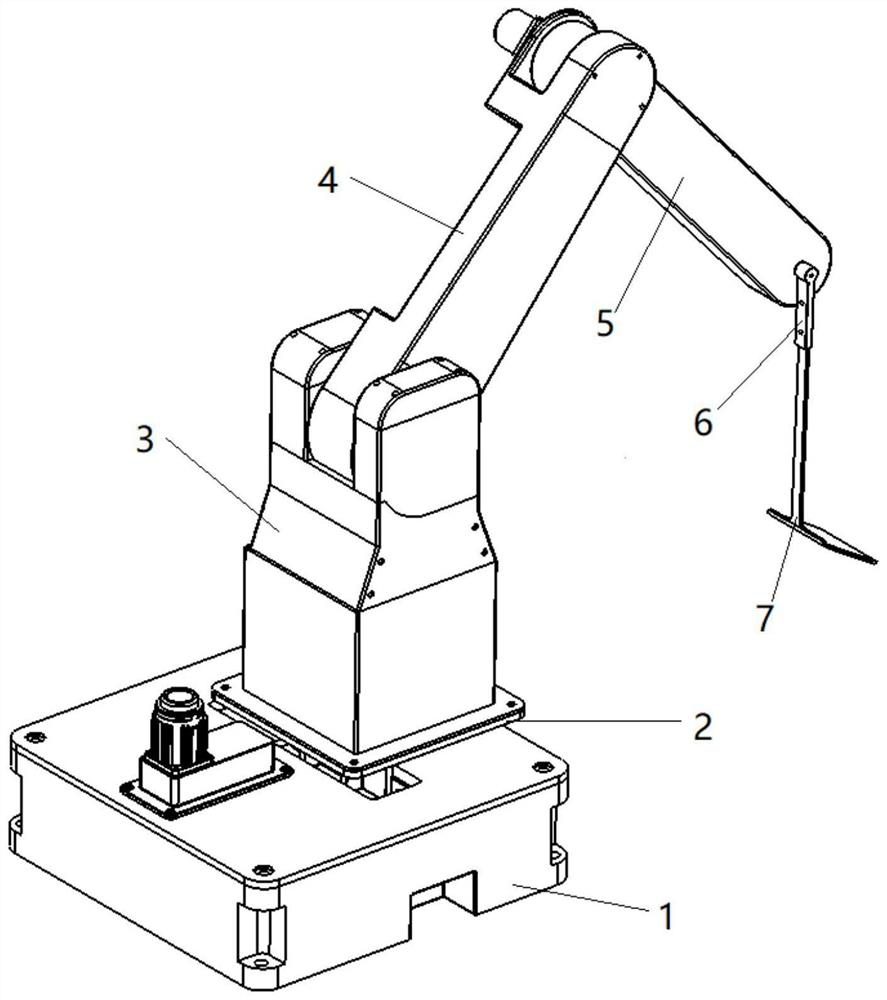

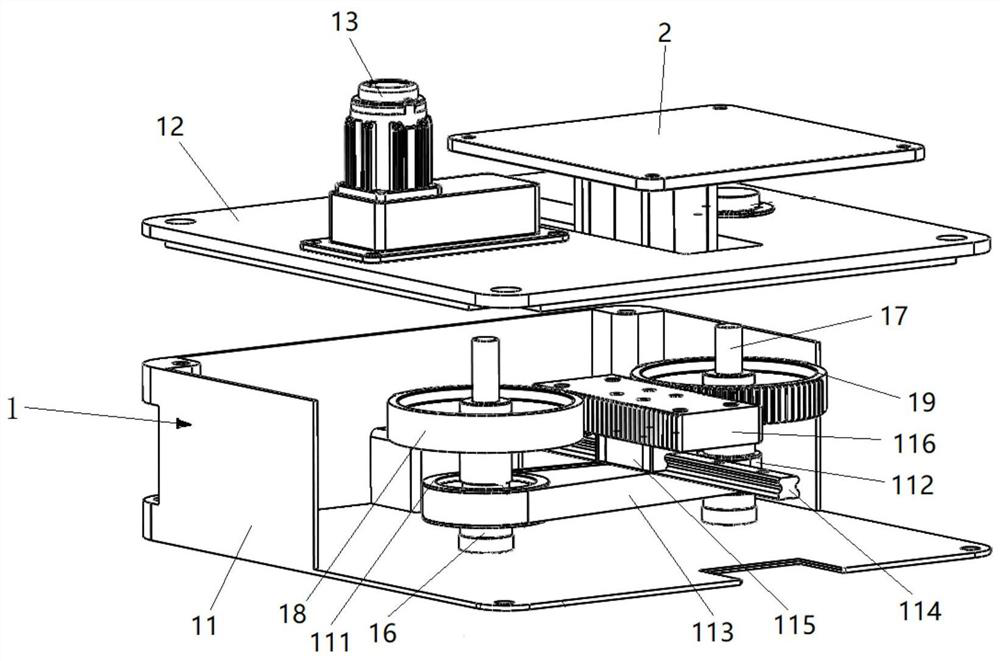

[0025] Embodiment: a kind of zinc alloy slag removal robot, such as Figure 1-7 As shown, the synchronous mobile device 1 is included, the top of the synchronous mobile device 1 is connected with the mechanical arm base 3 through the mechanical arm bracket 2, the mechanical arm arm device 4 is installed on the mechanical arm base 3, and the upper arm device 4 of the mechanical arm The top is connected with the mechanical arm forearm device 5, and the top of the mechanical arm forearm device 5 is equipped with the mechanical arm wrist 6, and the front end of the mechanical arm wrist 6 is provided with a slag removal plate 7. In the present invention, through the cooperation of the synchronous moving device 1, the base of the mechanical arm 3, the large arm device 4 of the mechanical arm, the small arm device 5 of the mechanical arm and the wrist part 6 of the mechanical arm, the slag removal work can be automatically completed on the zinc alloy pouring production line without ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com