Preparation method and application of no-clean high-nickel single-crystal lithium nickel cobalt manganate positive electrode material

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the field of lithium-ion power batteries for new energy vehicles, can solve the problems of high residual alkali on the surface and affect the safety performance of batteries, and achieve the effect of avoiding unfriendly environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

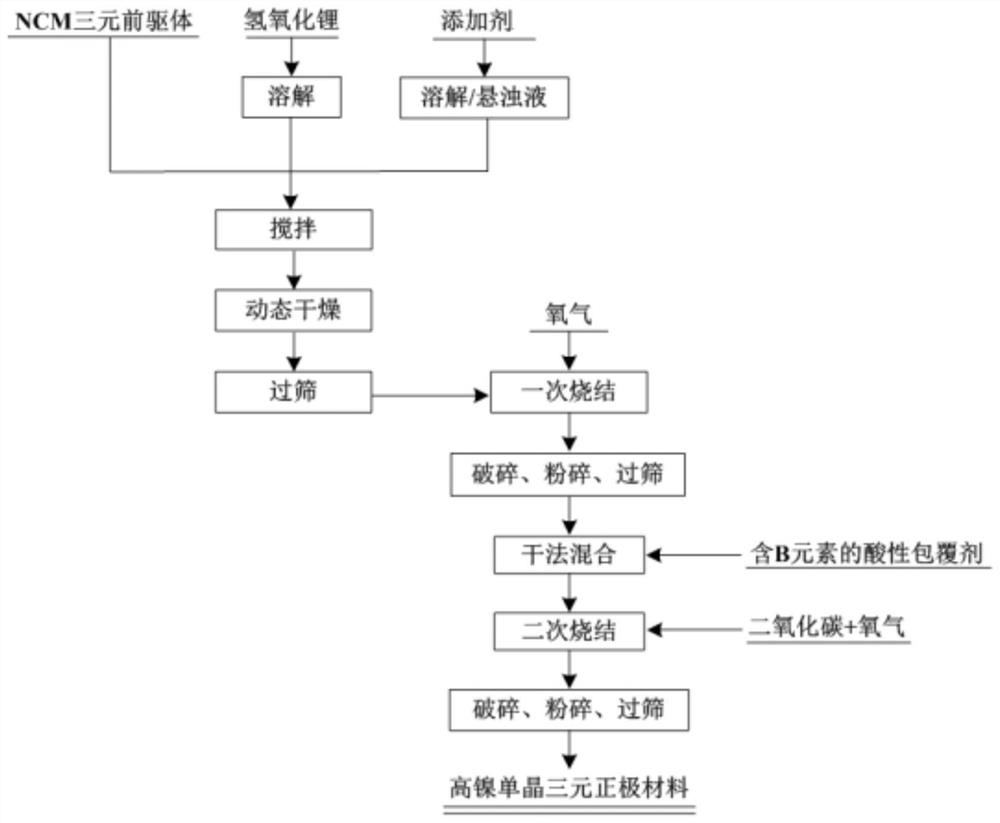

Method used

Image

Examples

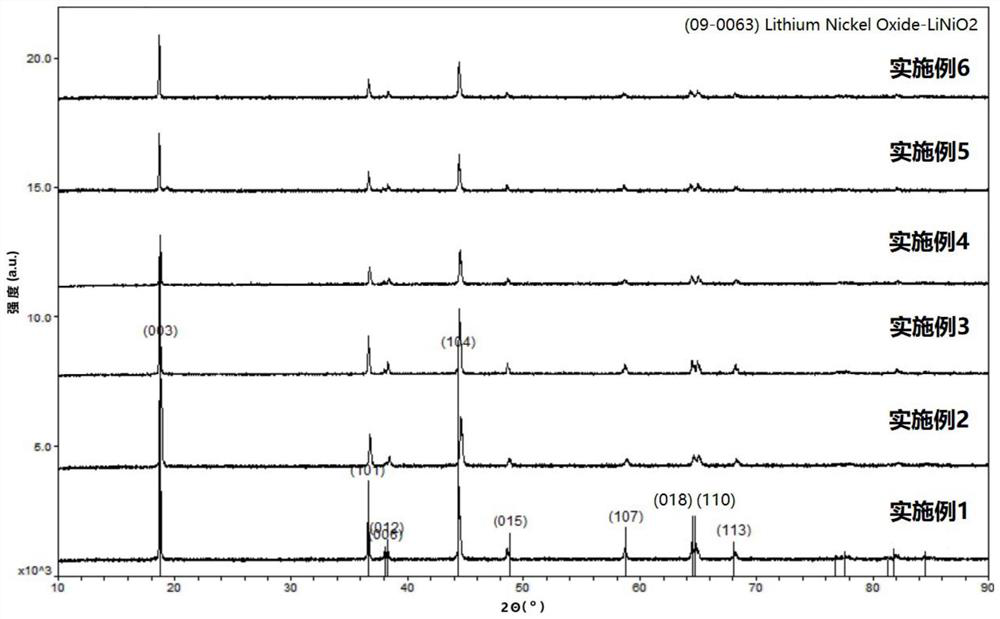

Embodiment 1

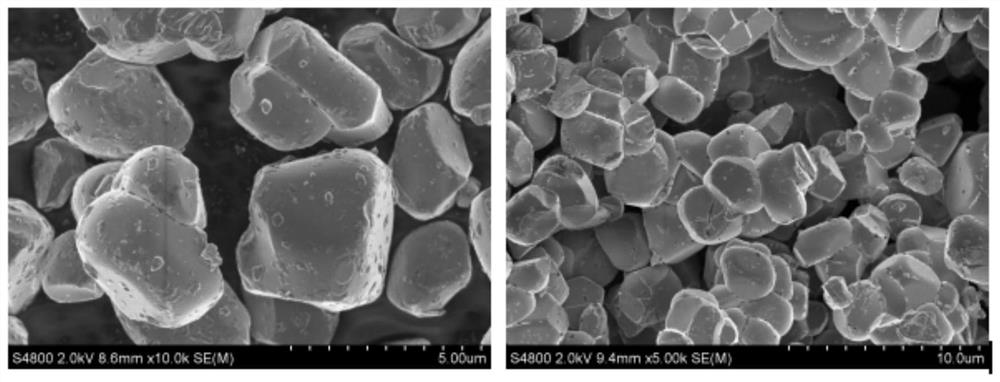

[0075] First, set D50 to 3.8 um and BET to 4.2 m 2 / g of small particle ternary precursor material Ni 0.8 co 0.1 mn 0.1 (OH) 2 (The NCM ternary precursor is prepared by a batch method, and the specific surface area BET is less than 5 m 2 / g; the cross-sectional morphology of the sphere is radially distributed, without obvious stratification, holes or cracks; the average grain size D50: 3.0-4.0 um), lithium hydroxide solution, and aluminum hydroxide suspension are placed in a ball mill tank, and the High-speed ball milling to mix evenly; wherein, the molar ratio of lithium element: precursor metal element is 1.04, and the mass fraction of aluminum element added in the total material is 2000 ppmw. After ball milling for 2 hours, put the slurry into the rotary spray drying equipment for rapid drying; then, the dried material is sintered once under the condition of high-purity oxygen at a temperature of 760°C, kept for 14 hours, and cooled ; Then go through jaw crushing, doub...

Embodiment 2

[0078] First, set D50 to 3.8 um and BET to 4.2 m 2 / g of small particle ternary precursor material Ni 0.8 co 0.1 mn 0.1 (OH) 2 , lithium hydroxide solution, and zirconium sulfate solution are placed in a ball mill tank, and are mixed uniformly by high-speed ball milling; wherein, the molar ratio of lithium: precursor metal element is 1.04, and the mass fraction of zirconium element added to the total material is 2000 ppmw. After ball milling for 2 hours, put the slurry into the rotary spray drying equipment for rapid drying; then, the dried material is sintered once under the condition of high-purity oxygen at a temperature of 760°C, kept for 14 hours, and cooled ; Then, go through jaw crushing, double rollers, crushing and sieving respectively; the conditions of jaw crushing, double rollers, crushing and sieving are as follows: inlet pressure: 0.8 MPa; gap between jaw crushing and double rollers: 0.2 mm; airflow crushing frequency : 150 Hz; grading frequency: 50 Hz, sievi...

Embodiment 3

[0081] First, set D50 to 3.8 um and BET to 4.2 m 2 / g of small particle ternary precursor material Ni 0.80 co 0.10 mn 0.10 (OH) 2 , lithium hydroxide solution, and magnesium chloride solution are placed in a ball mill tank, and are mixed uniformly by high-speed ball milling; wherein, the molar ratio of lithium: precursor metal element is 1.04, and the mass fraction of the added amount of magnesium element in the total material is 2000 ppmw. After ball milling for 2 hours, put the slurry into the rotary spray drying equipment for rapid drying; then, the dried material is sintered once under the condition of high-purity oxygen at a temperature of 760°C, kept for 14 hours, and cooled ; Then, go through jaw crushing, double rollers, crushing and sieving respectively; the conditions of jaw crushing, double rollers, crushing and sieving are as follows: inlet pressure: 0.8 MPa; gap between jaw crushing and double rollers: 0.2 mm; airflow crushing frequency : 150 Hz; grading frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com