Sheet type buffer device for new energy automobile battery

A technology of new energy vehicles and buffer devices, applied in battery/fuel cell control devices, electric vehicles, secondary batteries, etc., can solve the problems of buffer structure occupying space, no longer suitable for battery pack buffer, single buffer function of buffer structure, etc. , to achieve the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

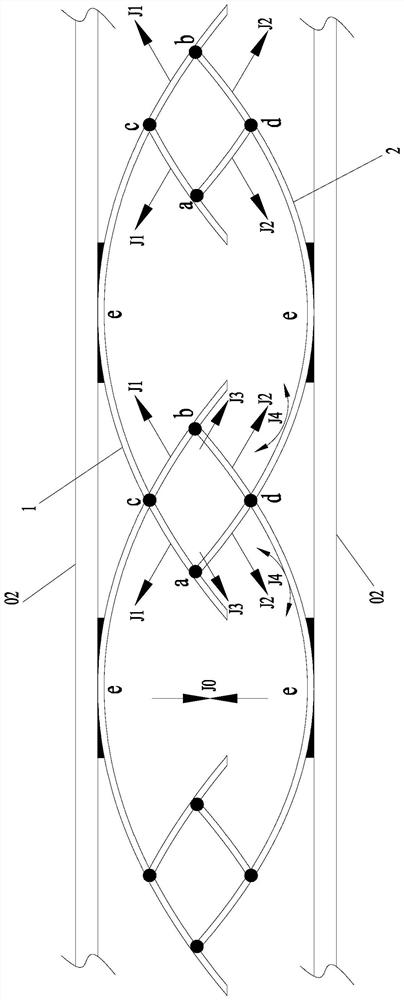

[0037] Such as figure 1 As shown, the present invention provides a sheet-type buffer device for a new energy vehicle battery, which includes two parallel substrates 02, and several buffer bodies 01 are arranged between the two substrates 02, that is, the buffer body 01 is covered by two substrates. 02 clamping;

[0038] Wherein, the buffer body 01 includes a first elastic body 1 and a second elastic body 2 that are joined together. The first elastic body 1 and the second elastic body 2 are both arc-shaped plates. Specifically, the first elastic body 1 and the second elastic body The arc corresponding to the two elastic bodies 2 is a part of a parabola, a hyperbola or an ellipse, because the ellipse is a closed figure, so when it is an elliptical structure, it needs to be a part of the ellipse; in the present embodiment, the elastic body adopts a parabola structure, while a plurality of buffer bodies 01 located between two substrates 02 are distributed in a linear array, and t...

Embodiment 2

[0049] In this embodiment, on the basis of Embodiment 1, the arrangement form of the buffer body 01 is changed, that is, as image 3 As shown, two adjacent buffer bodies 01 are rotationally symmetrical, and there is a gap between two adjacent first elastic bodies 1 or between two adjacent second elastic bodies 2, the gap is set to avoid deformation When , two adjacent buffer bodies 01 come into contact; it is equivalent to figure 1 On the basis of , rotate the two buffer bodies 01 separated by 180 degrees;

[0050] This distribution method can still form overlapping spaces and enclosed spaces. Compared with Example 1, due to this arrangement, the upper layer is not all the first elastic body 1, and the lower layer is not all the second elastic body 2. In the upper and lower layers, the first elastic body 1 and the second elastic body 2 are alternately distributed, and because the opening of the first elastic body 1 covers the opening of the second elastic body 2, this distrib...

Embodiment 3

[0053] On the basis of Example 1, the angles formed between the opening end and the tip of the first elastic body 1 and the second elastic body 2 are all acute angles, that is, as Figure 5 As shown in P;

[0054] Such as Figure 5 As shown, the overlapping space at this time is still surrounded by two floating ends a and b and two fixed ends c and d. For the two adjacent buffer bodies 01 and two substrates 02 The enclosed space is still enclosed by two e and d or two e and c, and shares the fixed ends c and d with the overlapping space.

[0055] Such as Figure 6 As shown, when two substrates 02 generate relative motion, that is Figure 6 When moving in the direction of J0, the buffer body 01 will deform at this time. Taking one of the overlapping spaces and the enclosed space as an example, because the included angle P has changed, the corresponding deformation has also changed, as follows:

[0056] For the overlapping space, there are still two fixed ends c, d and two f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com