Tail gas sulfur-containing substance concentration real-time prediction method based on stack type auto-encoder

A stack-type auto-encoder and auto-encoder technology is applied in the field of real-time prediction of the concentration of sulfur-containing substances in exhaust gas based on the stack-type auto-encoder, which can solve the problems of information loss, unsupervised, and lost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

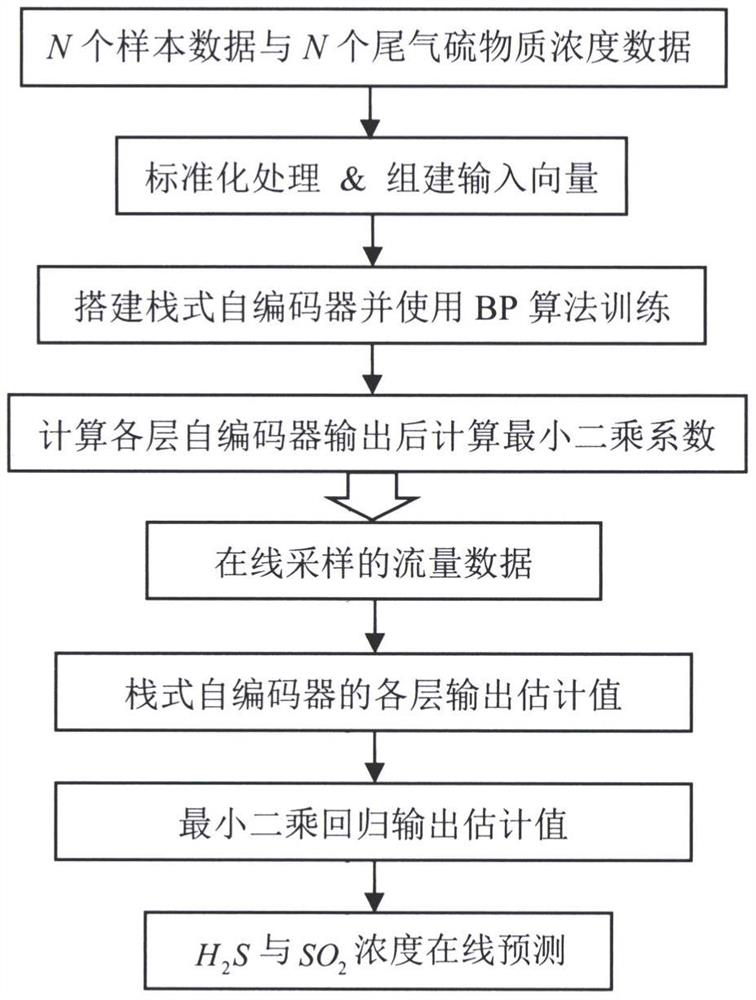

[0048] Such as figure 1 As shown, the present invention discloses a method for real-time prediction of the concentration of sulfur-containing substances in tail gas based on a stacked autoencoder. The specific implementation of the method of the present invention will be described below in conjunction with a specific application example.

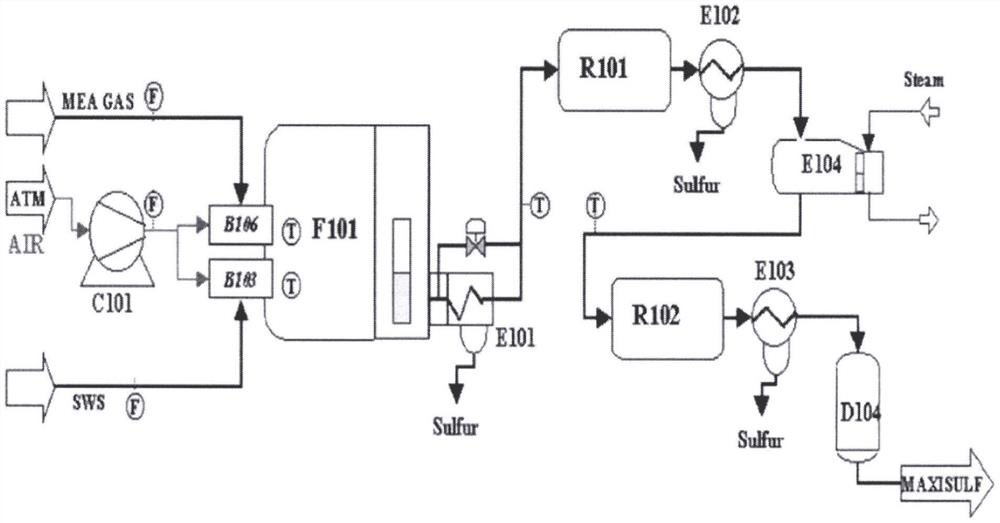

[0049] Such as figure 2 As shown, the industrial sulfur recovery unit recovers the sulfur in the industrial acid gas to produce by-products through the parallel operation of four subunits. The content of sulfur substances in the treated tail gas has been effectively reduced, so as to meet the environmental protection production requirements of petrochemical enterprises. The specific composition of the industrial sulfur recovery unit includes: a reaction furnace (F101) with two independent combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com