Special test device and method for hydrogen fuel cell system fuel cell stack offline

A fuel cell system and testing equipment technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., to achieve high uniformity, improve detection speed, and small system volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

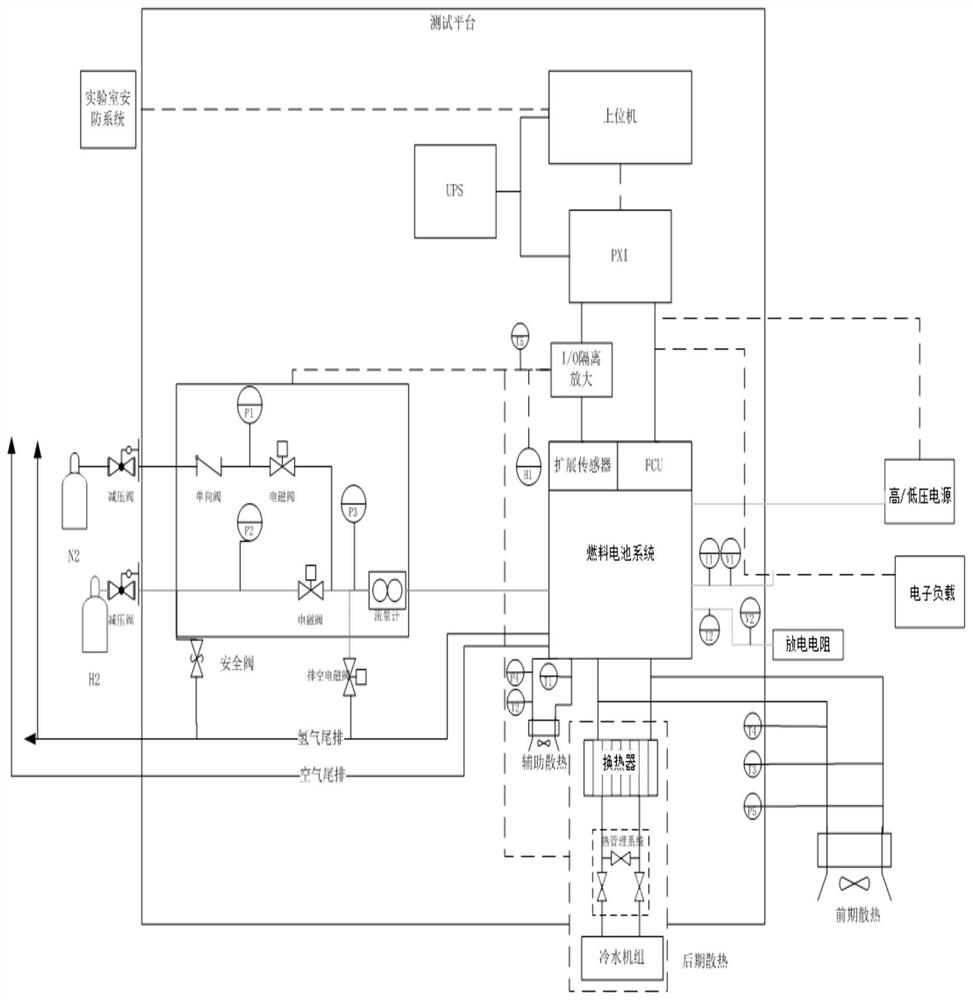

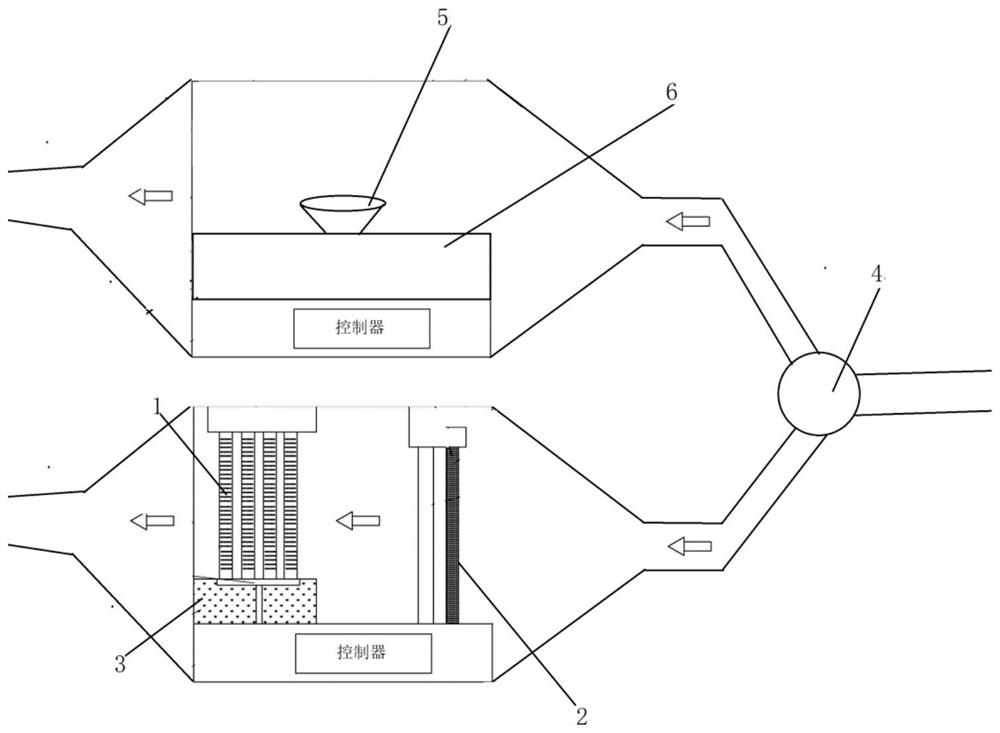

[0031] Such as figure 1 As shown, the platform mainly includes air supply and exhaust auxiliary system, main heat dissipation system, auxiliary heat dissipation system, high voltage power supply, low voltage power supply, electronic load, PXI control system and host computer, etc. A hydrogen fuel cell system stack off-line special test equipment, including air supply and exhaust auxiliary system, heat dissipation system, power supply, electronic load, PXI control system and host computer, the air supply and exhaust auxiliary system consists of humidity sensor, humidity Control device, filter, pressure reducer, hydrogen mass flow meter, air guide pipe and mechanical safety valve, the humidity control device is externally connected to the air guide pipe through a three-way valve, the humidity control device is composed of air inlet, condensation device, evaporating device, and air outlet, the air inlet is connected to the air guide pipe through a three-way valve, the air inlet i...

Embodiment 2

[0047] The composition of the test bench of the present invention mainly includes six subsystems: first, the gas supply, which mainly solves the gas supply of hydrogen, nitrogen and air, flow control, and flow, temperature, pressure and other measurement processing. The second subsystem is temperature control, because after the chemical reaction of hydrogen and oxygen in the fuel cell system of the object under test, a large amount of heat will be generated, and it is necessary to take the heat outside through such a form of heat exchange. The third is that during the reaction process, a large amount of water, a small amount of unreacted hydrogen and excess air will also be produced, which are further separated through such a tail row subsystem, and then discharged to the outside. The fourth is the electrical subsystem, which mainly solves the control of power electronics, high and low voltage DC power supply, signal collection, data forwarding, fault alarm and processing, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com