Method for judging the conductivity type of a semiconductor material in non-contact manner

A non-contact, conductive type of technology, applied in the direction of semiconductor characterization, single semiconductor device testing, electrical measurement, etc., can solve the problems of complex process, slow speed, wrong conclusion, etc., and achieve the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

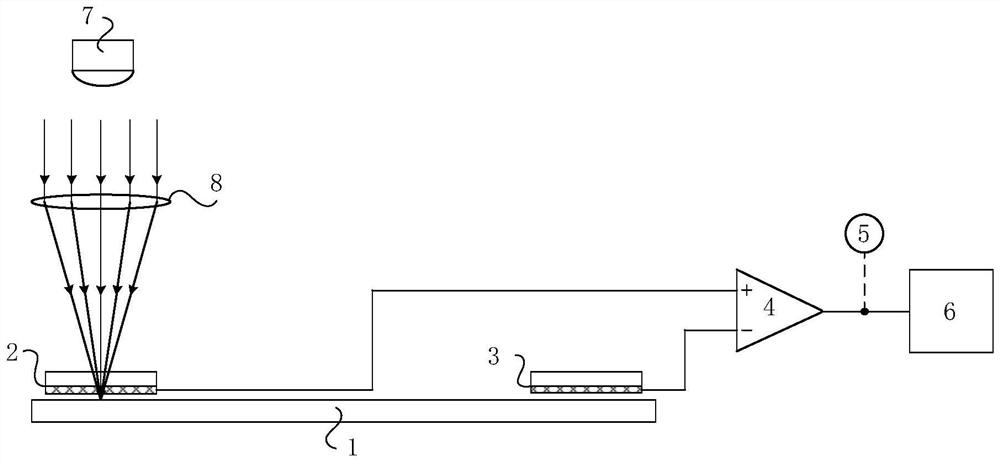

[0015] Such as figure 1 As shown, a non-contact method for judging the conductivity type of semiconductor materials, specifically:

[0016] A measurement electrode 2 and a reference electrode 3 are arranged above the surface of the semiconductor wafer 1 to be measured. The measuring electrode 2 and the reference electrode 3 are transparent conductive glass with the same size and shape. The orthographic projections of the measuring electrode 2 and the reference electrode 3 are within the scope of the semiconductor wafer 1 to be tested, and the mutual center distance between the two is greater than 3 times of the size of the electrodes themselves.

[0017] The measuring electrode 2 and the reference electrode 3 are close to the surface of the semiconductor wafer 1 to be measured, and its conductive surface faces downward, facing the surface of the semiconductor wafer 1 to be measured, and the distance between the measuring electrode 2 and the reference electrode 3 is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com