Catalytic luminescence reactor, and detection device and detection method of butanone peroxide

A technology of butanone peroxide and a detection device, applied in the field of detection, can solve the problems of butanone peroxide explosion, safety hazards of people's life and property, etc., and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] The preparation method of the nanometer yttrium oxide that the present invention adopts comprises the steps:

[0090] Mix the ethanol solution of yttrium salt with sodium citrate, add sodium hydroxide solution under stirring conditions, and continue stirring for 10-20 minutes to obtain a suspension;

[0091] The suspension is subjected to solid-liquid separation, and the solid is collected for washing and drying;

[0092] Calcining the dried solid; the temperature of the calcination is 600±20° C., and the calcination time is 2-3 hours.

[0093] In a specific embodiment of the invention, the yttrium salt comprises yttrium nitrate.

[0094] The nano-yttrium oxide prepared by the above method has a certain particle size, shape, crystal form, etc., which further ensures the effectiveness of catalytic luminescence detection.

[0095] The preparation method of the nanometer yttrium oxide that adopts in following specific embodiment can comprise the steps: the In(NO of 0.766...

Embodiment 1

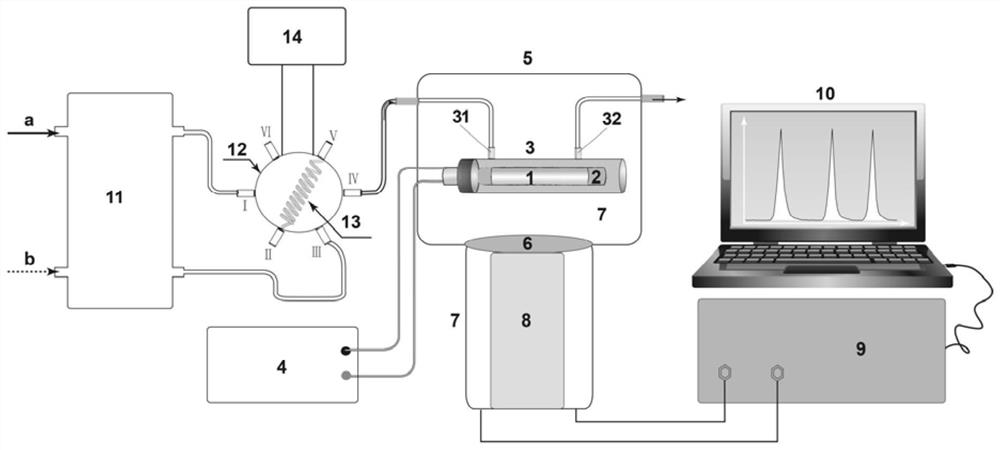

[0109] This example provides the use of figure 1 The detection device of shown butanone peroxide carries out the detection method of butanone peroxide, comprises the steps:

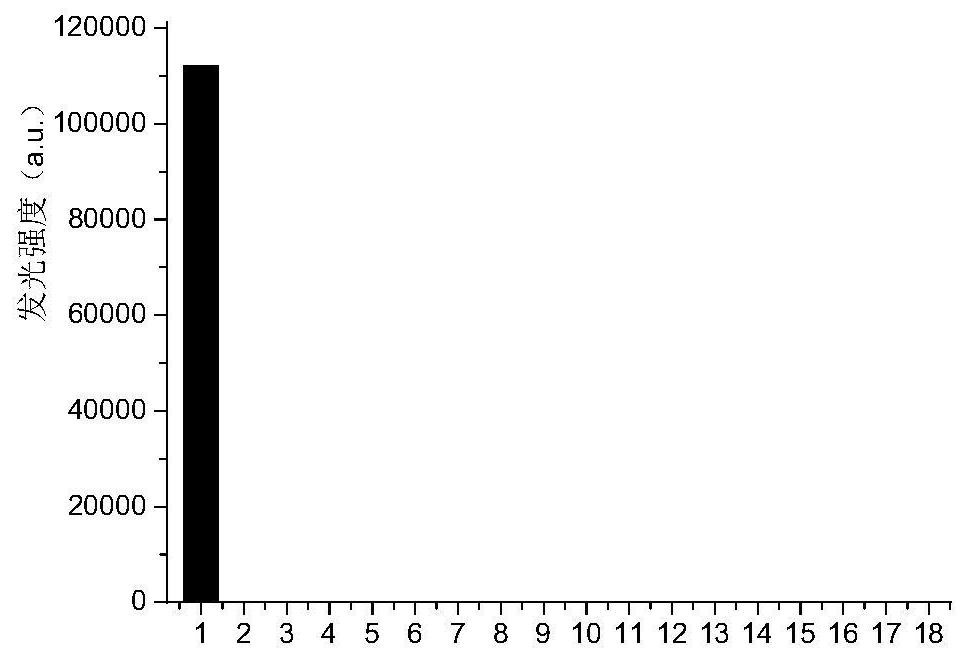

[0110] (1) adopt headspace gas distribution method preparation concentration to be the butanone peroxide gas of 200ppbv, as gas to be measured;

[0111] (2) Control the sampling valve to be in the energized state through the relay, start the sampling pump 11, and the gas to be tested is sent into the quantitative loop through the first channel a through the first valve port I and the second valve port II of the sampling valve, so that the gas to be tested Fill the quantitative loop and complete the sampling; the dry and clean carrier gas is sent from the second channel b through the third valve port III and the fourth valve port IV of the sampling valve into the quartz chamber to remove other gas impurities in the chamber; the carrier gas The flow rate is 240mL / min;

[0112] (3) Start the voltage regula...

Embodiment 2

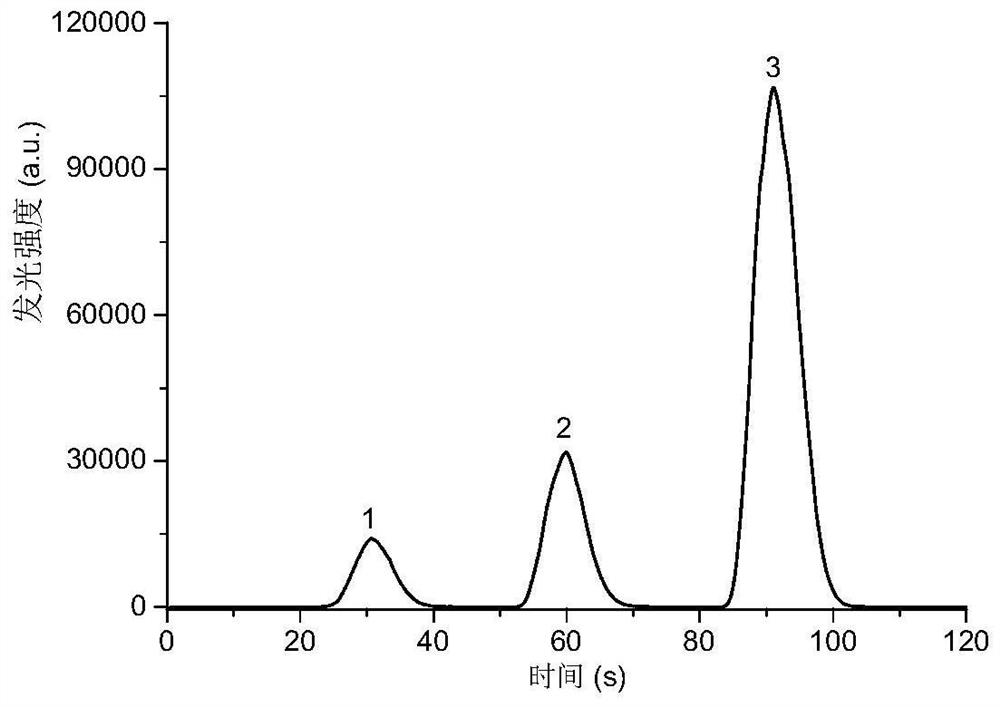

[0120] This embodiment refers to the detection method of Example 1, the difference is that: under the conditions of detection wavelength of 425nm, reaction temperature of 80°C, and carrier gas flow rate of 240mL / min, the peroxidation concentrations of 30ppbv, 60ppbv and 200ppbv were respectively measured successively. Butanone gas, the gas sampling time of three concentrations is 20s, 50s and 80s respectively, the kinetic response curve obtained is as follows image 3 shown.

[0121] image 3 Among them, 1, 2 and 3 on the curve represent the kinetic response curves of the methyl ethyl ketone peroxide gas whose concentration is 30ppbv, 60ppbv and 200ppbv respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com