Quantitative evaluation method for analyzing concrete workability based on bottom resistance

A quantitative evaluation and concrete technology, applied in the direction of analyzing materials, measuring devices, flow characteristics, etc., can solve the problems of lack of accuracy, inability to quantitatively standardize, expensive price, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The quantitative evaluation method based on bottom resistance analysis concrete workability of the present invention, comprises the following steps:

[0031] (1) Carry out the bottom resistance test of freshly mixed concrete:

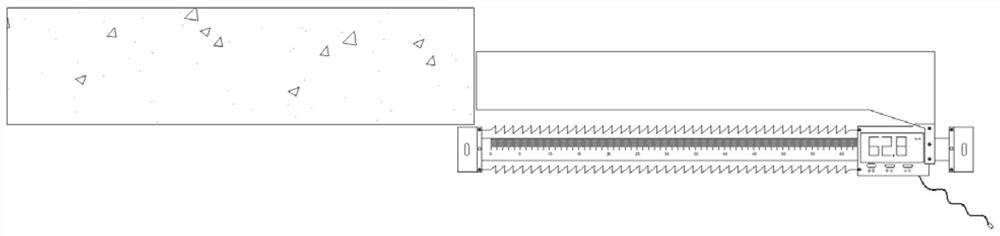

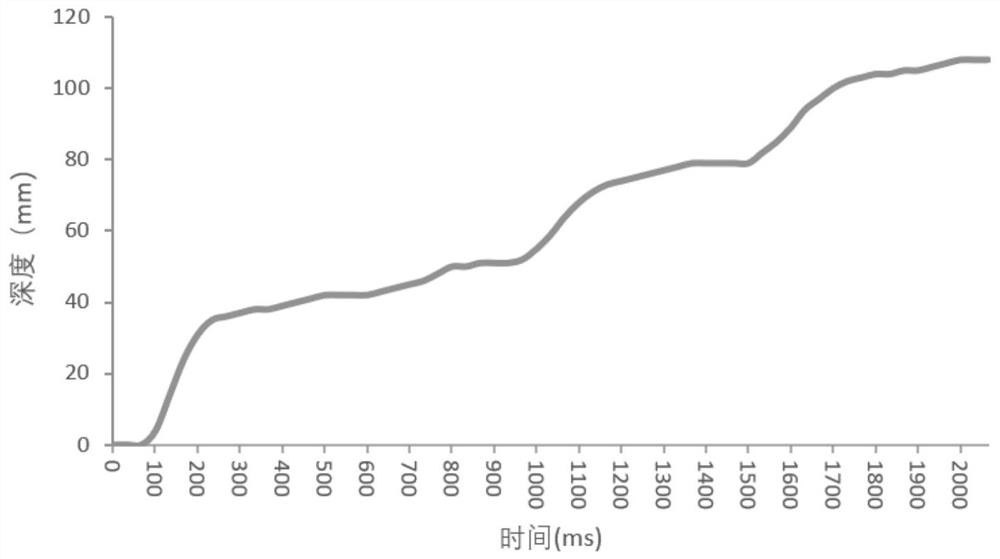

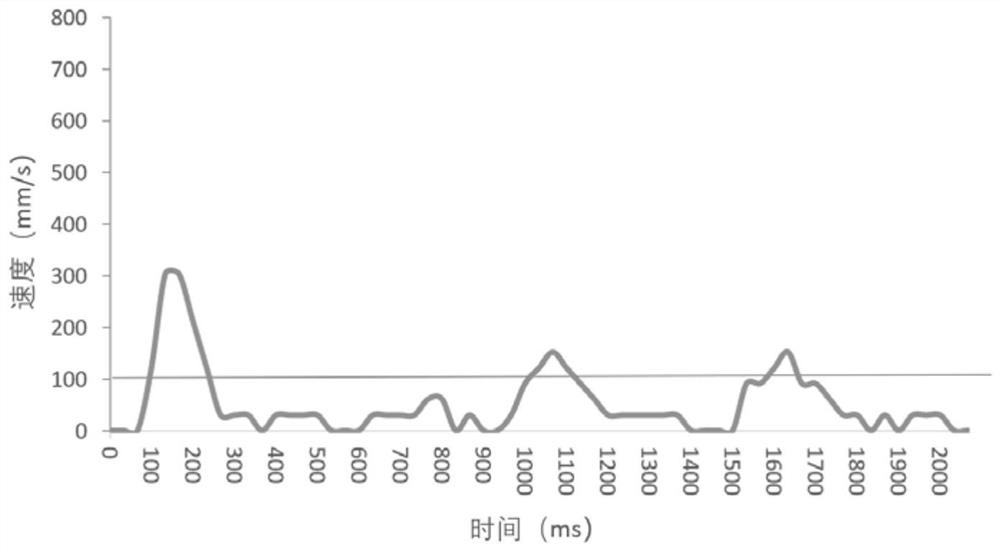

[0032] Mix water, cement, sand, gravel and water reducing agent in proportion to prepare fresh concrete for use. The mass ratio of water: cement: sand: gravel is 1:2.22:3.65:4.65. Add 0.44% water-reducing agent with the quality of cementitious material, and the concrete has serious segregation and bleeding at this time. Fill the concrete container with fresh concrete, and wipe the surface of the concrete container after full vibration. Fix the steel sheet and spring on the digital display scale with screws, and use the spring to provide insertion force, such as figure 1 shown. Pull the cursor of the scale to the bottom, so that the spring is in a stressed state, release the cursor, the steel ruler on the cursor is inserted into the bottom of t...

Embodiment 2

[0038] This embodiment is a quantitative evaluation method based on bottom resistance analysis of concrete workability, comprising the following steps:

[0039] (1) Carry out the bottom resistance test of freshly mixed concrete:

[0040] Mix water, cement, sand, gravel and water reducing agent in proportion to prepare fresh concrete for use. The mass ratio of water: cement: sand: gravel is 1:2.01:4.57:5.90. Add 0.44% water-reducing agent with the quality of cementitious material. At this time, the fluidity of the concrete is good, and there is no segregation and bleeding of the concrete by visual inspection. Fill the concrete container with fresh concrete, and wipe the surface of the concrete container after full vibration. Fix the steel sheet and spring on the digital display scale with screws, and use the spring to provide insertion force, such as figure 1 shown. Pull the cursor of the scale to the bottom, so that the spring is in a stressed state, release the cursor, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com