Automatic adjustment method and system for hydraulic balance of central air-conditioning system

A hydraulic balance and centralized air-conditioning technology, which is applied in the field of air-conditioning adjustment, can solve the problems of uneven heating and cooling in public areas, hydraulic imbalance of the centralized air-conditioning water system, and large gap in design flow, so as to save labor costs and simplify cumbersome steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]A method for automatically adjusting the hydraulic balance of a centralized air-conditioning system, comprising a multi-level pipeline mechanism, each pipeline of each level of pipeline mechanism is connected to a plurality of parallel lower-level pipelines, and the adjustment method includes the following steps:

[0051] S1. In the upper-level pipeline mechanism, select the pipeline with the largest flow ratio, and select the lower-level pipeline mechanism connected to this pipeline;

[0052] S2. In the lower-level pipeline mechanism, repeat the step S1 until reaching the lowest-level lower-level pipeline mechanism;

[0053] S3. In the pipeline mechanism at this level, adjusting the flow ratio of each pipeline specifically includes the following steps:

[0054] S31. Select the pipeline with the smallest flow ratio among the multiple pipelines of the pipeline mechanism as the reference value;

[0055] S32. Select a pipeline other than the reference value, and adjust the...

Embodiment 2

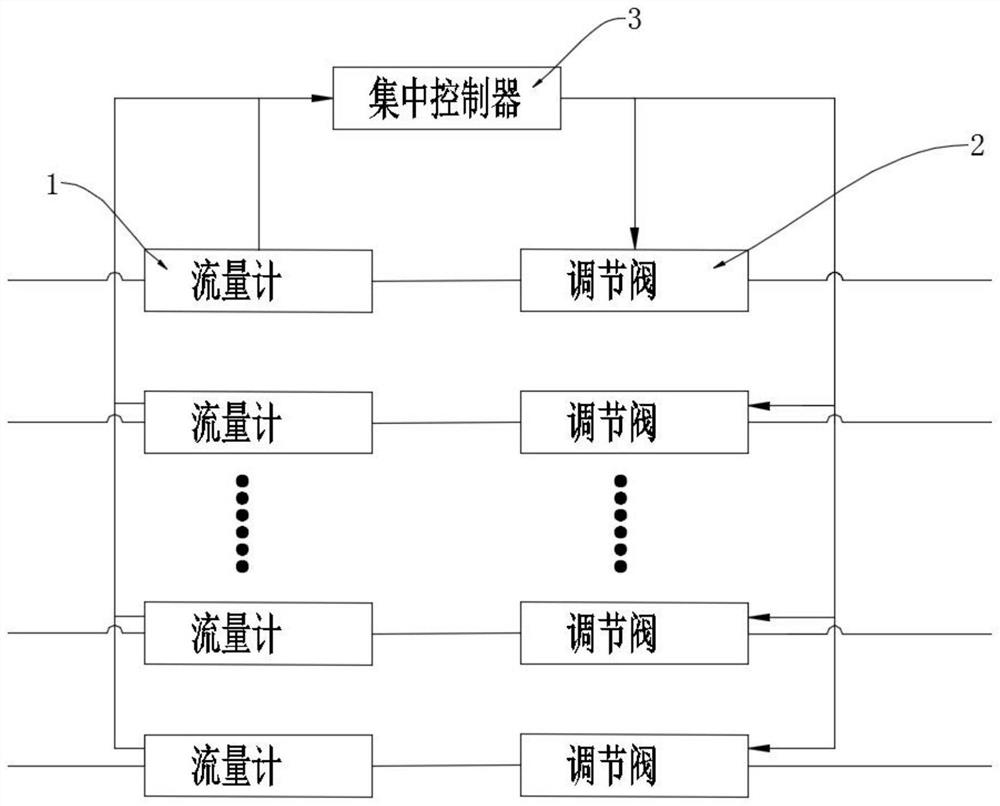

[0066] A centralized air conditioning system hydraulic balance automatic adjustment system, such as Figure 1-5 As shown, the system includes a multi-stage pipeline mechanism, each pipeline of the upper-level pipeline mechanism is connected to multiple parallel pipelines of the lower-level pipeline mechanism, and also includes a flow meter 1, a regulating valve 2 and a centralized controller 3 .

[0067] Both the flow meter 1 and the regulating valve 2 are installed on each pipeline of the multi-stage pipeline mechanism, and both are connected with the centralized controller 3 .

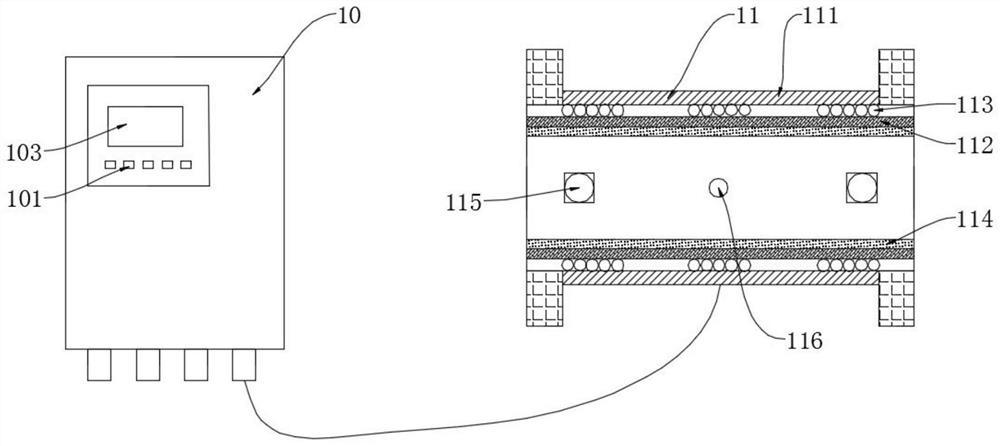

[0068] The flowmeter 1 includes: a button module 101, which is used to input the design flow of the pipeline; a processor 102, connected to the button module 101, receives the actual flow signal of the pipeline, calculates the ratio of the actual flow to the design flow, and transmits the ratio to the centralized control Device 3; a display module 103, connected to the processor 102, displays the rat...

Embodiment 3

[0086] In this embodiment, the method for automatically adjusting the hydraulic balance of the central air-conditioning system will be described in detail in combination with Embodiment 1 and Embodiment 2.

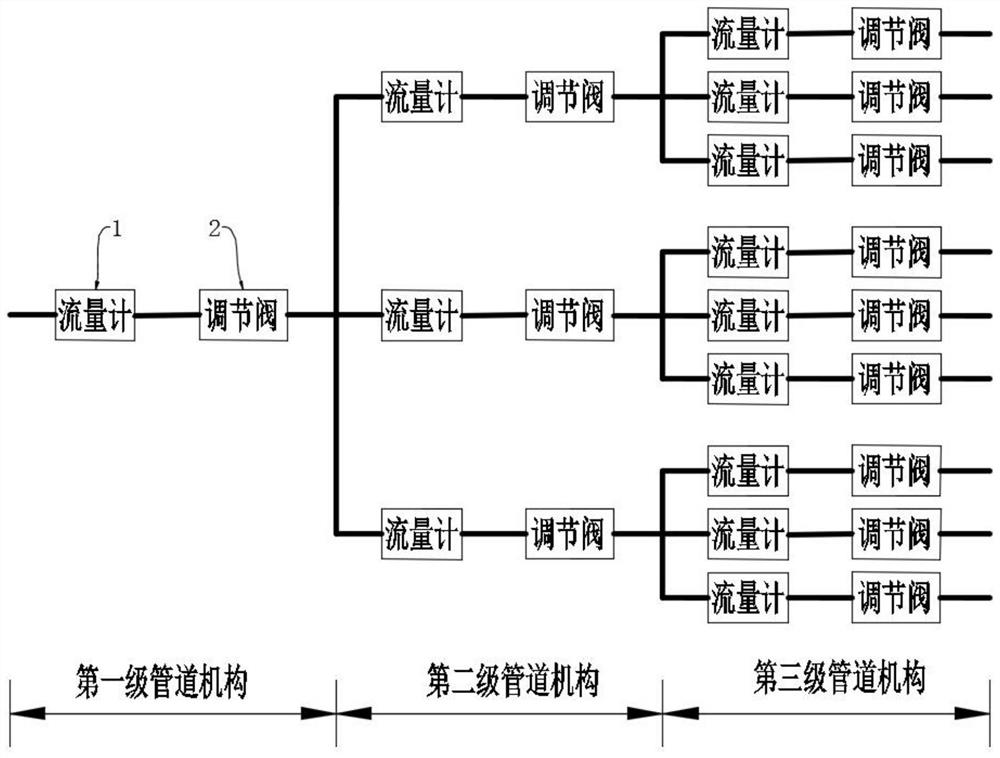

[0087] In this embodiment, the adjustment method is adapted to the three-level pipeline mechanism. The first-level pipeline mechanism is a first pipeline directly connected to the air-conditioning system, that is, the main water outlet pipe, and the second-level pipeline mechanism is three branches of the first pipeline. The second pipe, the third pipe mechanism are three third pipes branched from each second pipe, a total of nine pipes, such as figure 2 shown. On each pipeline, a flowmeter 1 and a regulating valve 2 are installed, and both the flowmeter 1 and the regulating valve 2 are connected to the centralized controller 3, and the centralized controller 3 receives the uploaded information of the flowmeter 1 and controls the flow of the regulating valve 2 run.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com