White long-afterglow luminescent material and preparation method thereof

A long afterglow luminous, white technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of easy formation of other substrates, serious material agglomeration, and various impurities, etc., and achieve excellent afterglow performance stability and uniform size distribution , the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

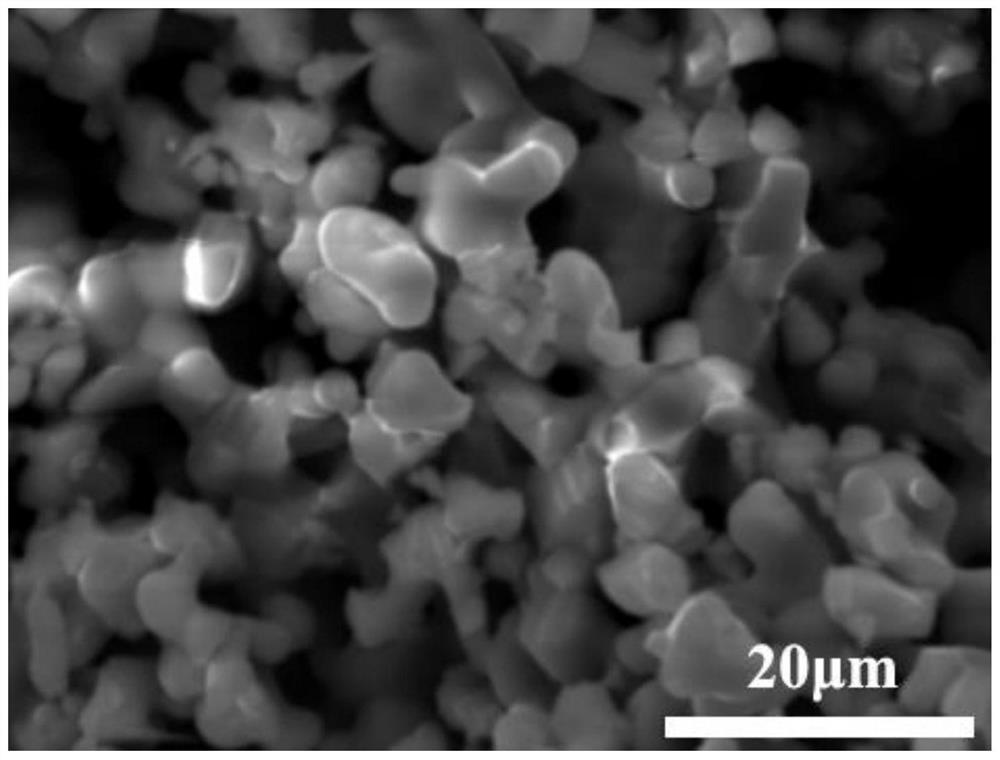

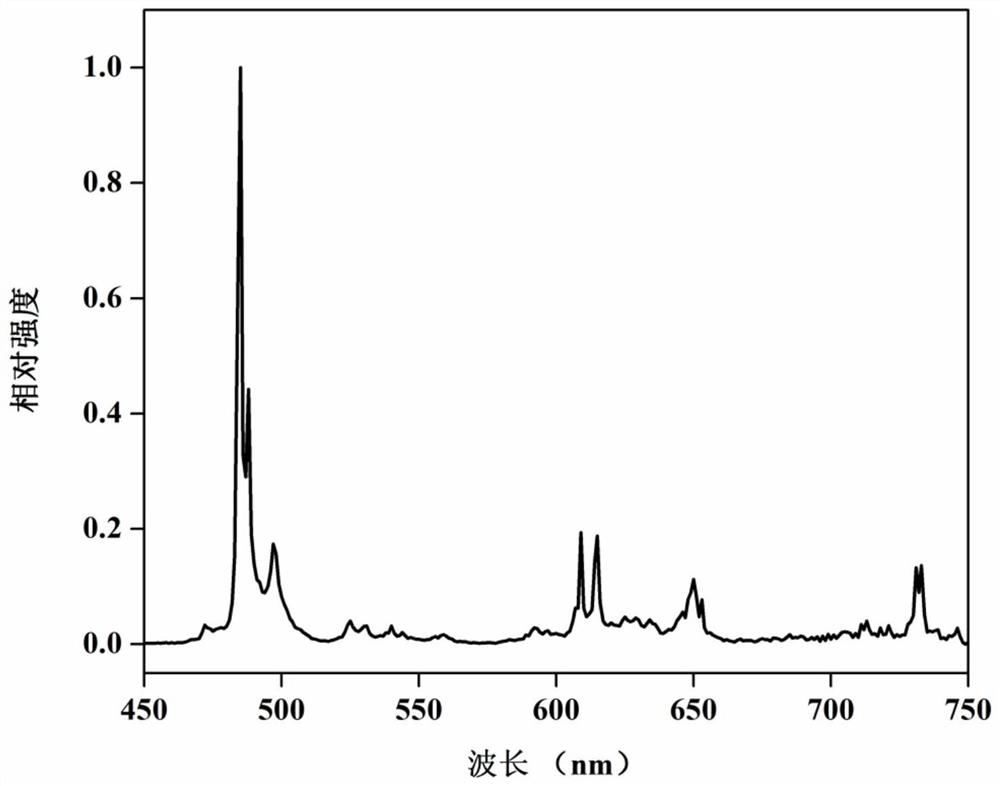

[0034] A white long-lasting luminescent material Ca 4.93 Ga 6 o 14 :Pr 0.07 3+ The preparation method is carried out as follows:

[0035] (1) Preparation of raw material powder

[0036] According to 0.5915gCaCO 3 , 0.6673gGa 2 o 3 and 0.0141g Pr 6 o 11 Mix as raw material, add absolute ethanol, the mass ratio of absolute ethanol to the total mass of raw materials is 1:1, grind at a temperature lower than 15°C, the grinding speed is 30 rpm, and the grinding time is 50 min. After grinding, put the powder in the Dry at 100°C for 2 hours;

[0037] (2) Composite calcination

[0038] Place the raw material powder prepared in step (1) in an air environment at 1250°C, sinter for 8 hours, cool to room temperature, and grind from inside to outside along the same direction. The grinding rate is 40 revolutions / min, and the grinding time is 25 minutes. Then in 10% by volume of H 2 and 90% by volume N 2 The composition is calcined for the second time in a reducing atmosphere a...

Embodiment 2

[0045] A white long-lasting luminescent material Ca 4.91 Ga 6 o 14 :Pr 0.09 3+ The preparation method is carried out as follows:

[0046] (1) Preparation of raw material powder

[0047] Weigh 0.5891gCaCO 3 , 0.6673gGa 2 o 3 and 0.0182g Pr 6 o 11 As a raw material, add absolute ethanol, the ratio of the mass of absolute ethanol to the total mass of raw materials is 1.1:1, grind at 10°C, the grinding rate is 30 rpm, and the grinding time is 45min. After grinding, put the powder at 100°C Dry for 2 hours;

[0048] (2) Composite calcination

[0049] The first calcination is to place the raw material powder in an air environment at 1280°C, sinter for 6 hours, and after cooling to room temperature, grind from the inside to the outside along the same direction, the grinding rate is 40 rpm, and the grinding time is 30 minutes. From 10% by volume H 2 and 90% by volume N 2 Calcined for the second time under the reducing atmosphere of the composition, the temperature is 950 ...

Embodiment 3

[0052] A white long-lasting luminescent material Ca 4.995 Ga 6 o 14 :Pr 0.005 3+ The preparation method is carried out as follows:

[0053] (1) Preparation of raw material powder

[0054] Weigh 0.5992gCaCO 3 , 0.6673gGa 2 o 3 and 0.001g Pr 6 o 11 As a raw material, add absolute ethanol, the ratio of the mass of absolute ethanol to the total mass of raw materials is 1.2:1, grind at 20°C, the grinding rate is 30 rpm, and dry the powder at 100°C for 2 hours after grinding;

[0055] (2) Composite calcination

[0056] The first calcination is to place the raw material powder in an air environment at 1210°C, sinter for 7 hours, and after cooling to room temperature, grind from the inside to the outside along the same direction, the grinding rate is 40 rpm, and the grinding time is 15 minutes. From 10% by volume H 2 and 90% by volume N 2 Calcined for the second time under the reducing atmosphere of the composition, the temperature is 900 ℃, sintered for 4h, cooled to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com