Continuous preparation and transfer method for meter-scale single-walled carbon nanotube film and special device

A technology of single-wall carbon nanotubes and transfer devices, applied in the direction of single-wall carbon nanotubes, nanotechnology, nanotechnology, etc., can solve the problems of discontinuous preparation process and small size of single-wall carbon nanotube films, and achieve continuous transfer , The effect of large film forming area and small film forming area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

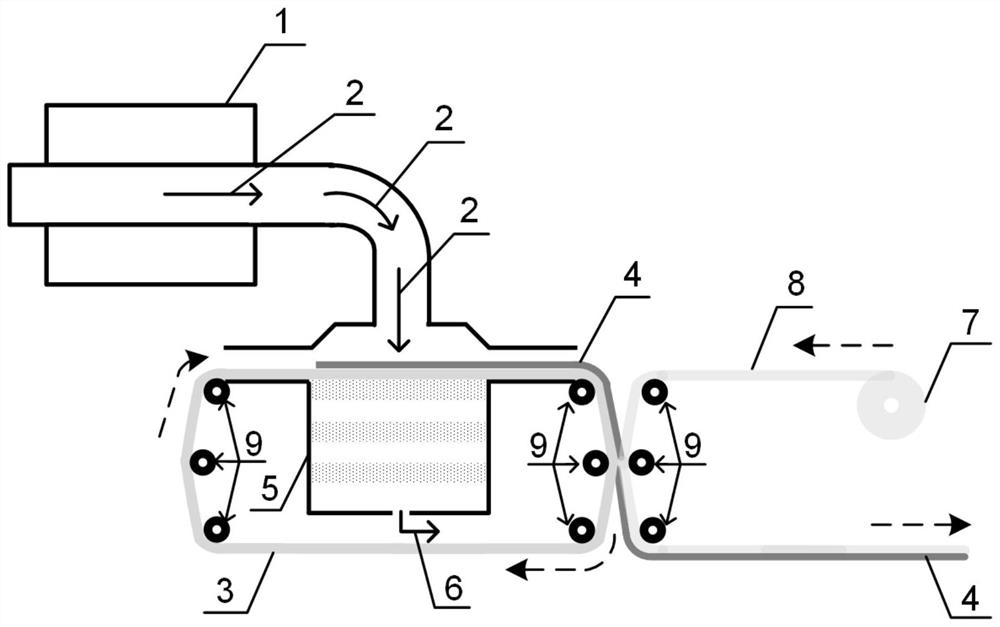

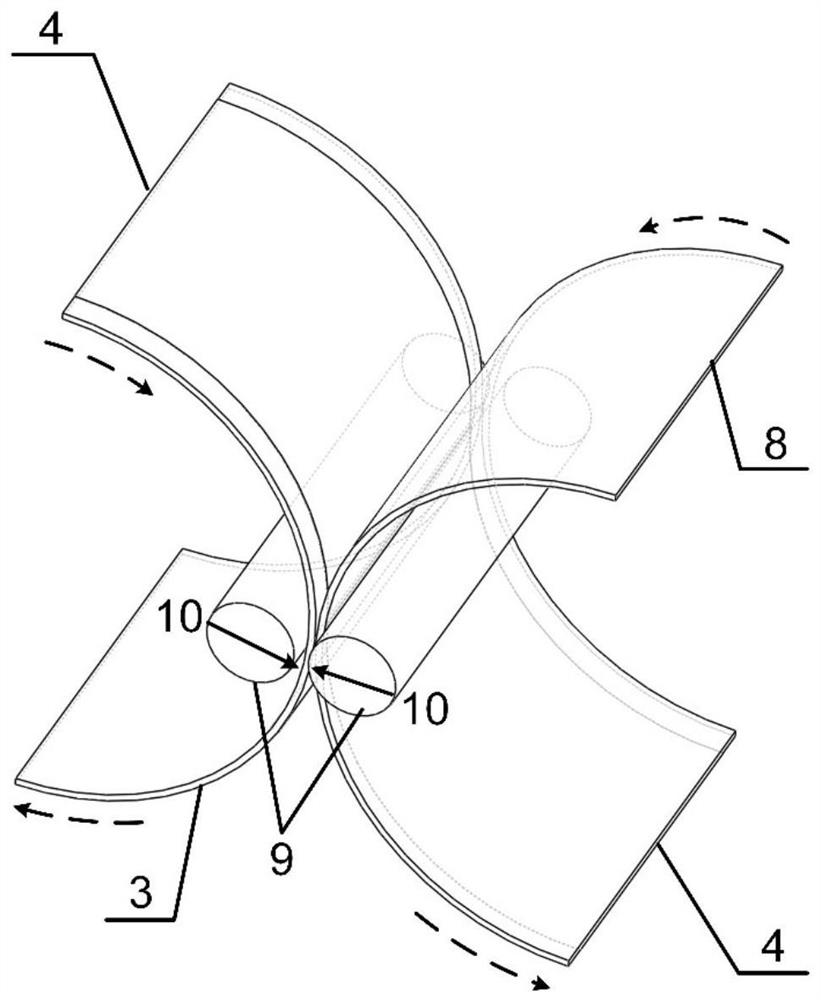

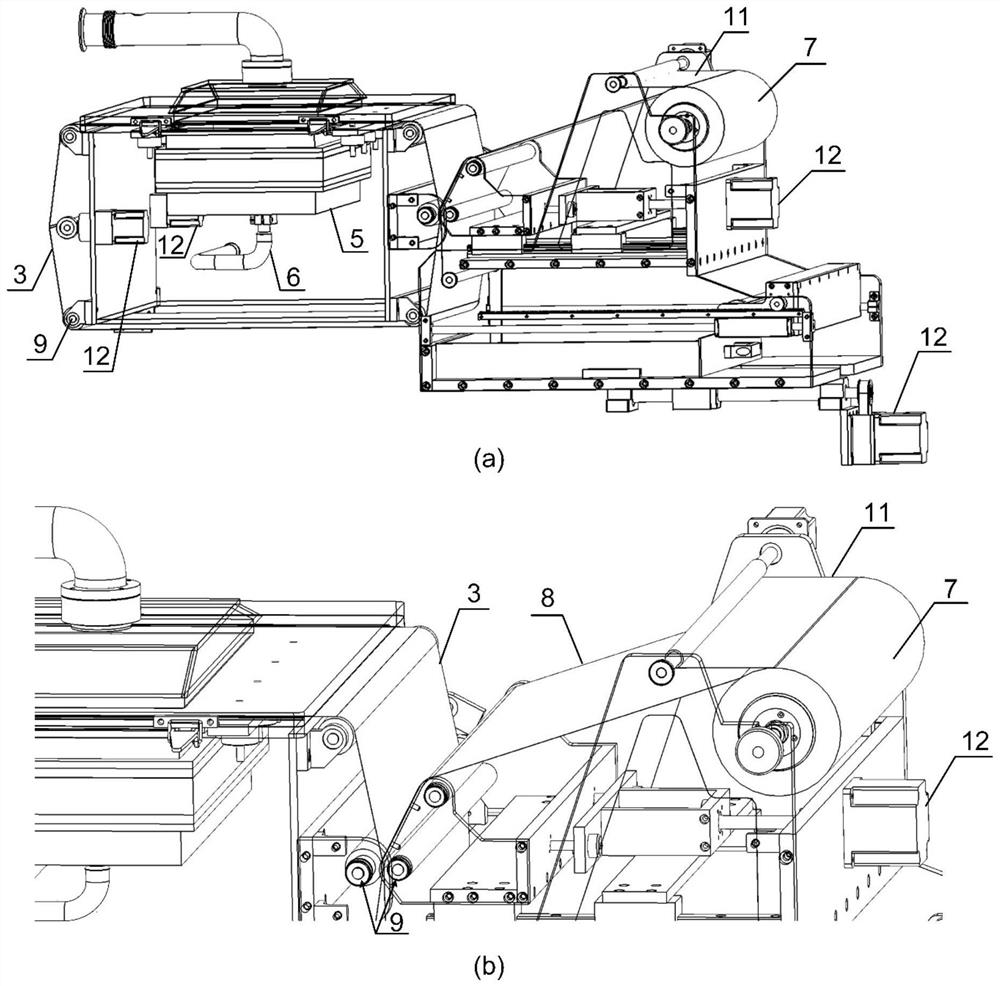

[0045] In this example, the continuous preparation and transfer process of single-walled carbon nanotube film is shown in figure 1 . Single-walled carbon nanotubes were prepared by floating catalyst chemical vapor deposition. The chemical vapor deposition reaction temperature was 1100 °C. Ferrocene, thiophene and toluene were prepared as a catalyst solution at a mass ratio of 6.7:1:222. The rate was 4 μL / min. The catalyst solution was injected into the tube furnace, and 8000 sccm hydrogen and 11 sccm ethylene were fed into the tube furnace at the same time, and the hydrogen and ethylene carried the catalyst into the constant temperature reaction zone of the tube furnace to synthesize single-walled carbon nanotubes. The synthesized single-wall carbon nanotubes flow into the gas-phase suction filter device from the end of the tube furnace with the carrier gas, and adjust the airflow rate at the gas-phase suction port so that all the about 8011sccm airflow flowing into the gas-ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com