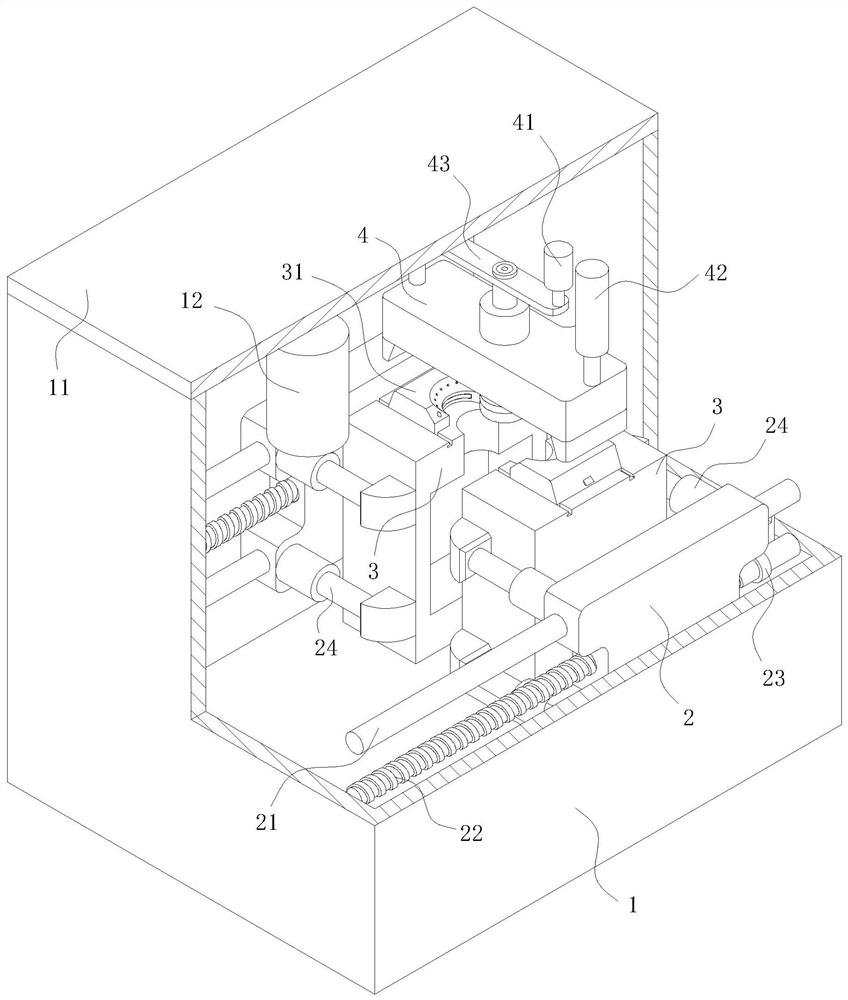

Blow molding process for children's slide components

A slide and component technology, which is applied in the field of children's slide parts blow molding process, can solve the problems of poor sealing between the blow pipe and the parison, and achieve the effects of uniform force, uniform side wall thickness, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

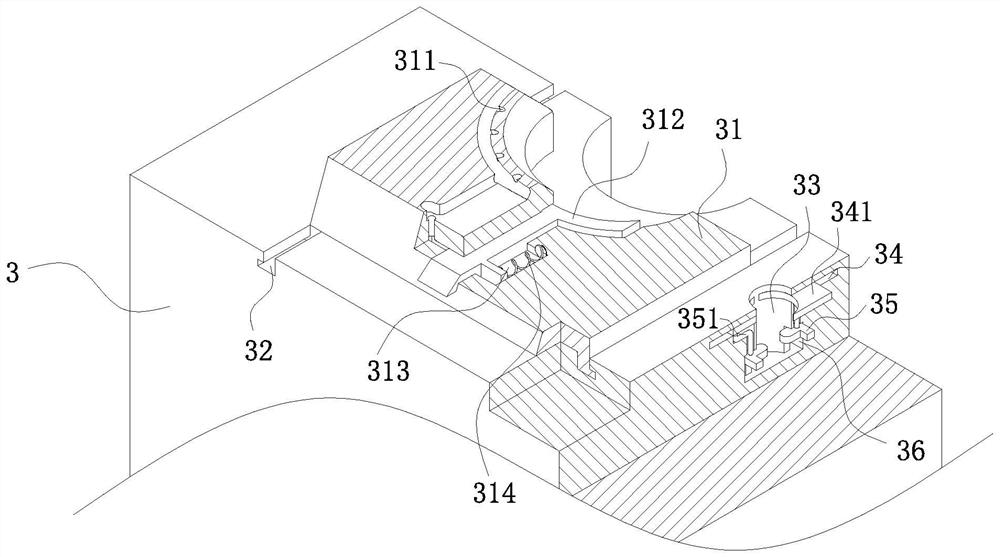

Examples

Embodiment approach

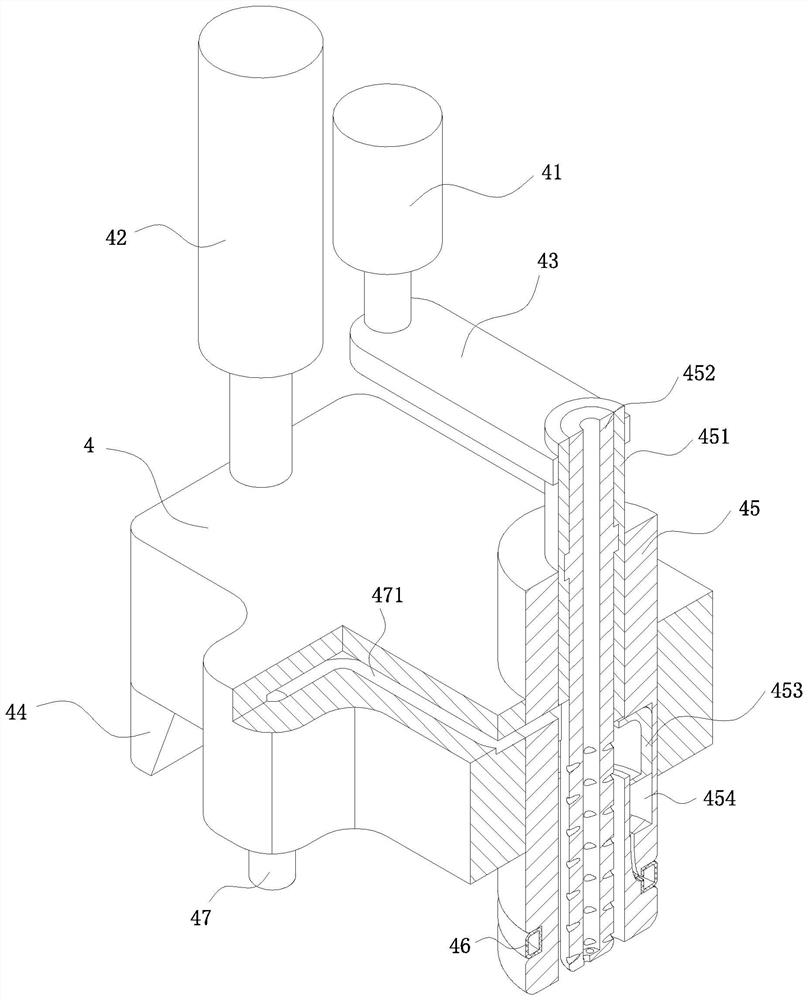

[0041] As an embodiment of the present invention, a rotating tube 452 is installed in the inner tube 451; the rotating tube 452 and the inner tube 451 can rotate mutually; the rotating tube 452 and the inner tube 451 Displacement cannot occur in the length direction; the side wall of the rotating tube 452 is provided with jet holes along the tangential direction;

[0042]When working, after the blowing pipe 45 is inserted into the mold 3, the controller controls the start of the cylinder 2 41 to insert the inner pipe 451 into the middle of the parison. The gas enters into the inside of the parison through the air injection holes on the rotating tube 452. Since the air injection holes are distributed along the tangential direction, when the air injection holes are spraying, the rotating tube 452 is subjected to the reaction force in the tangential direction, so that the rotating tube 452 rotates, and the gas entering the parison The high-pressure gas in the parison evenly acts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com