Finish machining auxiliary device suitable for concave-convex lens and uniform in cutting component force

An auxiliary device and convex lens technology, which is applied in the field of finishing parts, can solve the problems of lens deformation, deformation is difficult to control, and high defective rate, so as to improve the precision of finishing and reduce deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] All features disclosed in this specification, or steps in all methods or processes disclosed, can be combined in any way, except for mutually exclusive features and or steps.

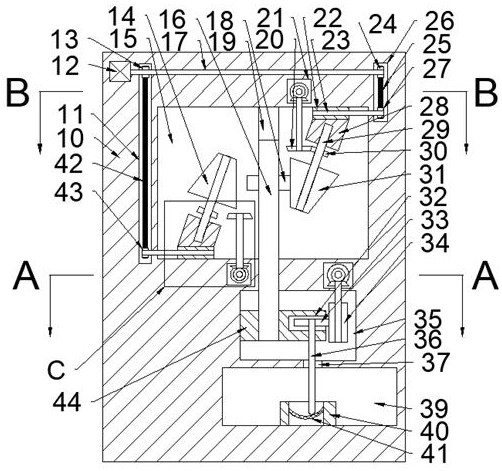

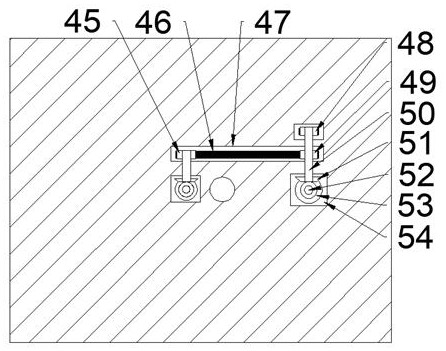

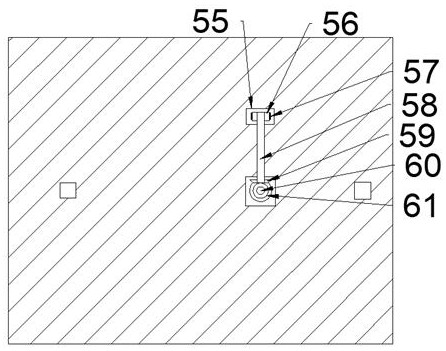

[0017] Combine below Figure 1-4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0018] Such as Figure 1-4 As shown, a finishing auxiliary device suitable for concave-convex lenses and uniform cutting force of the device of the present invention includes a main box body 10, a speed change chamber 15 is arranged in the main case body 10, and a speed change chamber 15 is arranged on the right side. There is a right belt chamber 26 extending upwards, and a right screw rod 23 extending rightward into the right belt chamber 26 and leftward into the transmission chamber 15 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com