PLC circuit board washing device and washing method

A technology of circuit boards and brushes, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problem of affecting the cleaning quality of PLC circuit boards, the impurity does not collect and guide, and the cleaning process of the impurity recovery box Slow etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

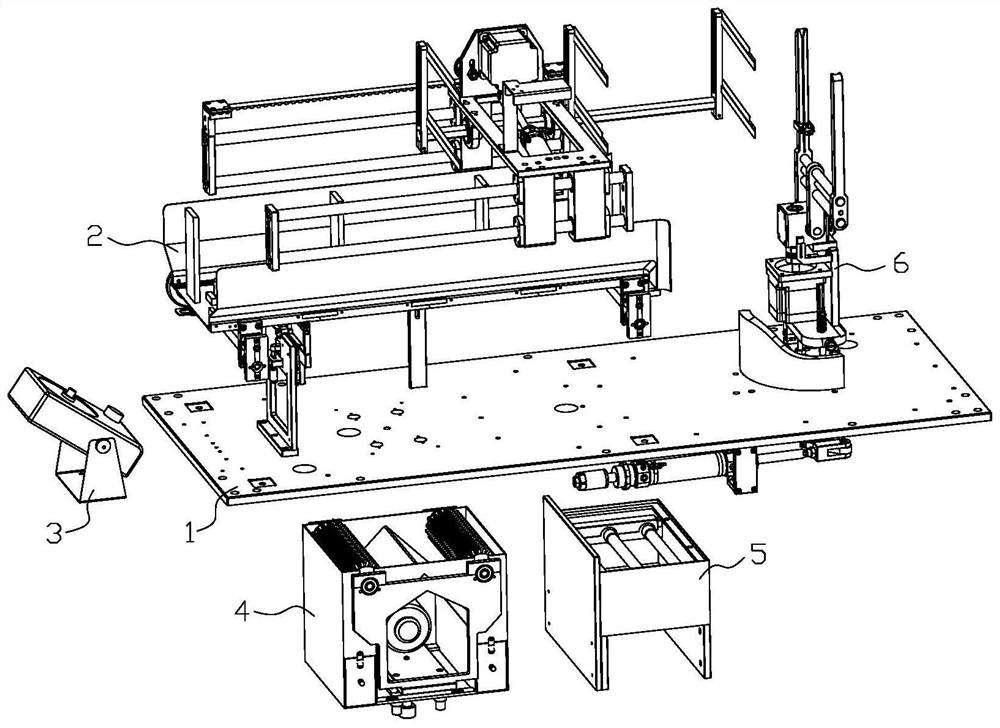

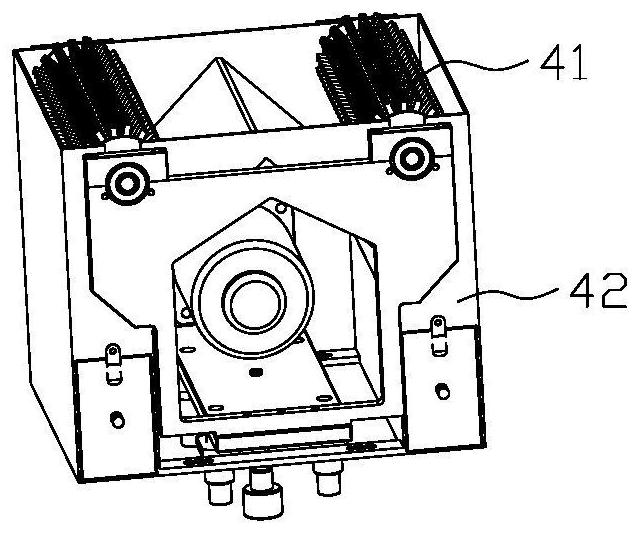

[0032] Such as figure 1 A PLC circuit board cleaning device is shown, which includes a workbench 1 and a circuit board conveying device 2 fixed on the workbench 1, a static elimination device 3, a circuit board scrubbing device 4, a circuit board drying device 5 and a circuit board Overturn air-drying device 6; circuit board conveying device 2 is respectively connected with static electricity removing device 3, circuit board scrubbing device 4, circuit board drying device 5 and circuit board overturning air-drying device 6; circuit board conveying device 2 is used for conveying PLC circuit boards ; Static removal device 3 is used to carry out electrostatic treatment to PLC circuit board; Circuit board scrubbing device 4 is used to wash away impurities on PLC circuit board; Circuit board drying device 5 is used to dry the PLC circuit board after washing; The circuit board overturning air-drying device 6 is used for rotary air-drying of PLC circuit boards.

[0033] The product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com