Flavoured chicken feet and processing technology thereof

A processing technology and technology for chicken feet, applied in the field of flavored chicken feet and its processing technology, can solve problems such as affecting the health of consumers, low nutritional value of chicken feet, and inability to precipitate nutrients, so as to retain nutrients and reduce nutrients. The loss of ingredients and the effect of convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

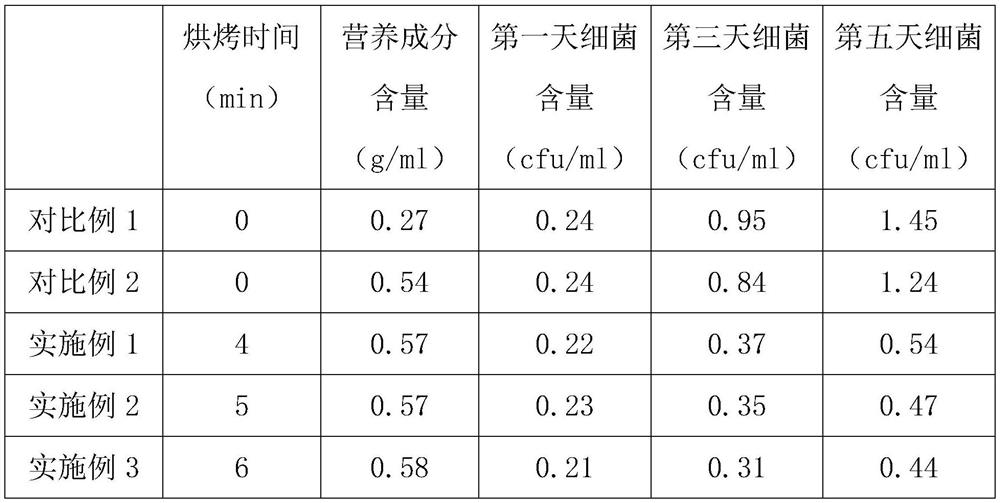

Examples

Embodiment 1

[0051] A flavored chicken feet, made of the following components in parts by weight: 550 parts of chicken feet, 23 parts of carrots, 3 parts of ginger, 23 parts of mature vinegar, 14 parts of edible salt, 53 parts of rice wine, 40 parts of wild pepper, 38 parts of red oil 5 parts of rock sugar, 3 parts of cinnamon, 32 parts of yam, 20 parts of peach kernel, 7 parts of angelica, 23 parts of parasitic, 74 parts of milk powder.

[0052] refer to figure 1 Shown, a kind of processing technology of local flavor chicken feet, the concrete steps of this processing technology are as follows:

[0053] Step 1: Clean the raw materials first, then put the rice wine, mature vinegar and milk powder into the container, and stir with a glass rod to obtain the soaking liquid. The mixing of the rice wine, mature vinegar and milk powder includes the following steps:

[0054] (1) Put milk powder and water first, the ratio of water to milk powder is 1:3, then stir for 5 minutes, pour mature vinega...

Embodiment 2

[0064] A flavored chicken feet, made of the following components in parts by weight: 550 parts of chicken feet, 23 parts of carrots, 3 parts of ginger, 23 parts of mature vinegar, 14 parts of edible salt, 53 parts of rice wine, 40 parts of wild pepper, 38 parts of red oil 5 parts of rock sugar, 3 parts of cinnamon, 32 parts of yam, 20 parts of peach kernel, 7 parts of angelica, 23 parts of parasitic, 74 parts of milk powder.

[0065] refer to figure 1 Shown, a kind of processing technology of local flavor chicken feet, the concrete steps of this processing technology are as follows:

[0066] Step 1: Clean the raw materials first, then put the rice wine, mature vinegar and milk powder into the container, and stir with a glass rod to obtain the soaking liquid. The mixing of the rice wine, mature vinegar and milk powder includes the following steps:

[0067] (1) Put milk powder and water first, the ratio of water to milk powder is 1:3, then stir for 5 minutes, pour mature vinega...

Embodiment 3

[0077] A flavored chicken feet, made of the following components in parts by weight: 550 parts of chicken feet, 23 parts of carrots, 3 parts of ginger, 23 parts of mature vinegar, 14 parts of edible salt, 53 parts of rice wine, 40 parts of wild pepper, 38 parts of red oil 5 parts of rock sugar, 3 parts of cinnamon, 32 parts of yam, 20 parts of peach kernel, 7 parts of angelica, 23 parts of parasitic, 74 parts of milk powder.

[0078] refer to figure 1 Shown, a kind of processing technology of local flavor chicken feet, the concrete steps of this processing technology are as follows:

[0079] Step 1: Clean the raw materials first, then put the rice wine, mature vinegar and milk powder into the container, and stir with a glass rod to obtain the soaking liquid. The mixing of the rice wine, mature vinegar and milk powder includes the following steps:

[0080] (1) Put milk powder and water first, the ratio of water to milk powder is 1:3, then stir for 5 minutes, pour mature vinega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com