360-degree plane 3D detection system and detection method based on X-RAY

A detection system and detection method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that affect the accuracy of product internal defect recognition, many gray scales, and poor image simulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

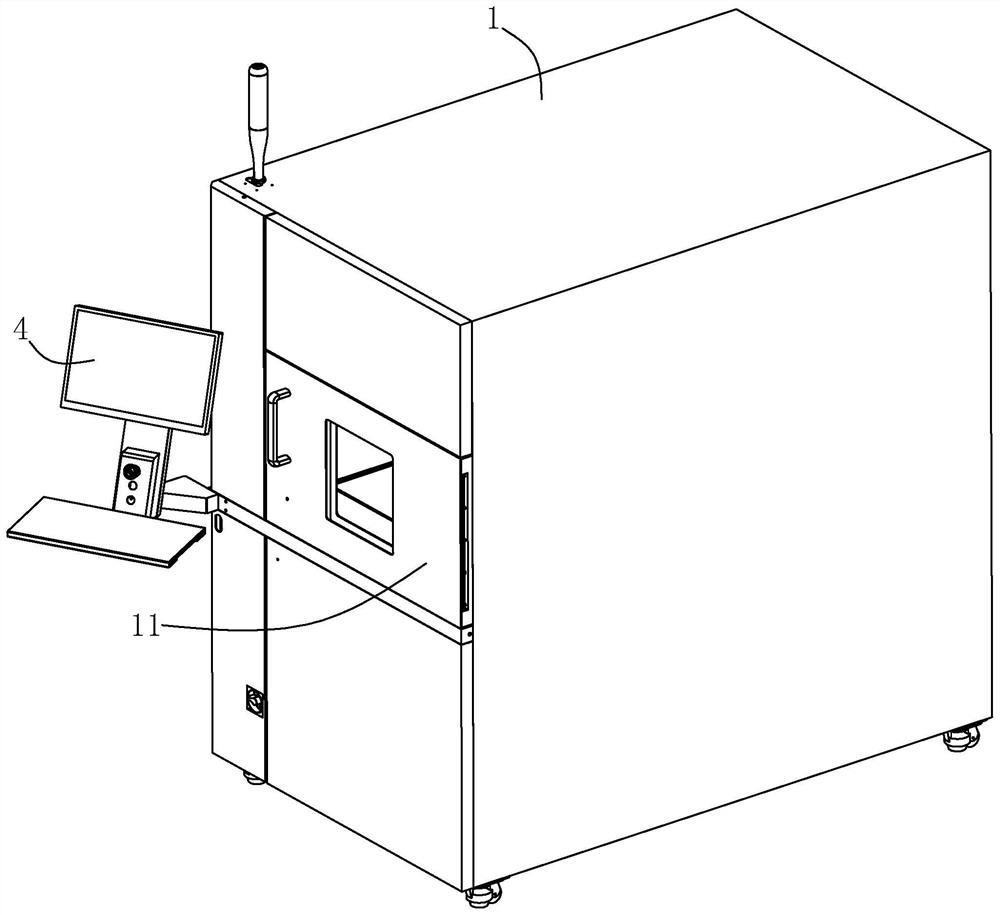

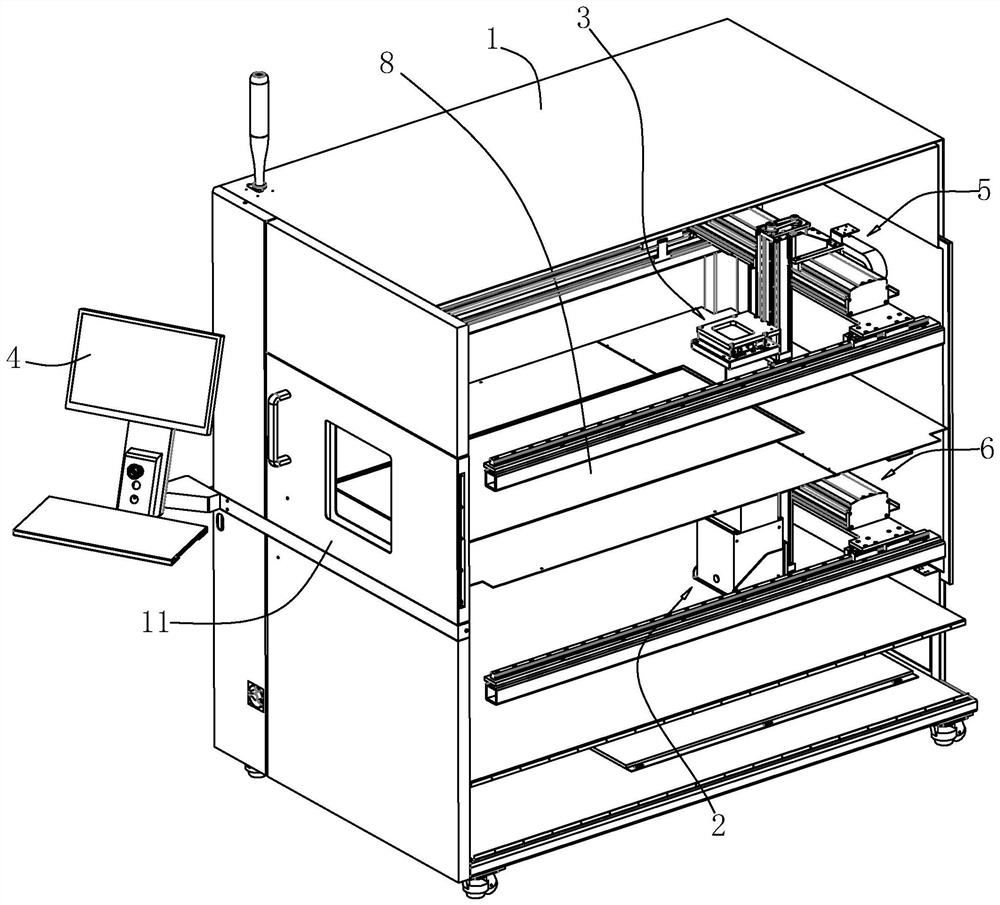

[0036] The application will be described in further detail below in conjunction with the accompanying drawings.

[0037] The embodiment of the present application discloses an X-RAY-based 360-degree plane 3D inspection method, which can improve the accuracy of identifying internal defects of products.

[0038] A 360-degree plane 3D detection method based on X-RAY comprises the following steps:

[0039] S1. Place the product between the X-ray emitting device 2 and the image receiving device 3, and align the positions of the X-ray emitting device 2 and the image receiving device 3 with the detection area of the product.

[0040] S2. Send X-rays to the detection area of the product through the X-ray emitting device 2, and the image receiving device 3 rotates around the projection point of the emission center of the X-ray emitting device 2 with a fixed radius, so as to receive the X-rays on the same plane at different angles to the product scanned images; specifically, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com