A method for controlling a magnetic suspension bearing system

A magnetic levitation bearing and control method technology, applied to magnetic bearings, bearings, shafts and bearings, etc., can solve difficult and impractical problems, and achieve the effects of avoiding calculation errors, improving precision, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below through specific embodiments.

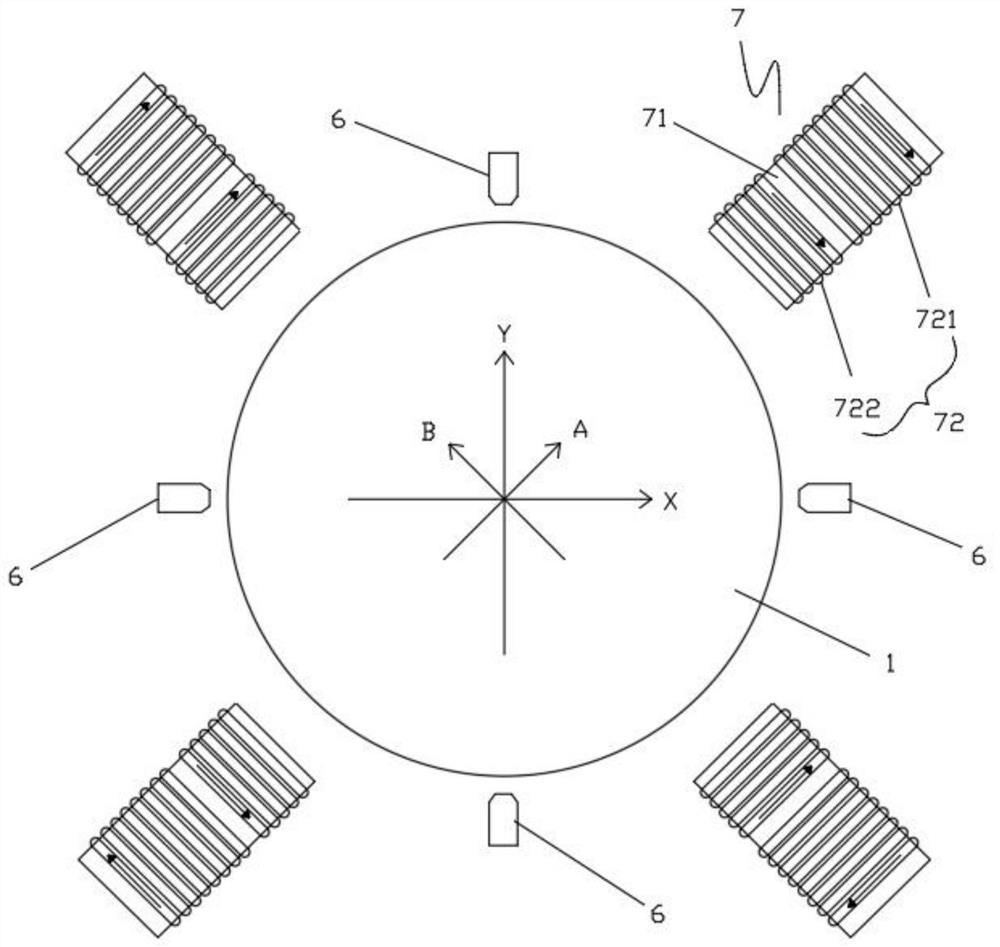

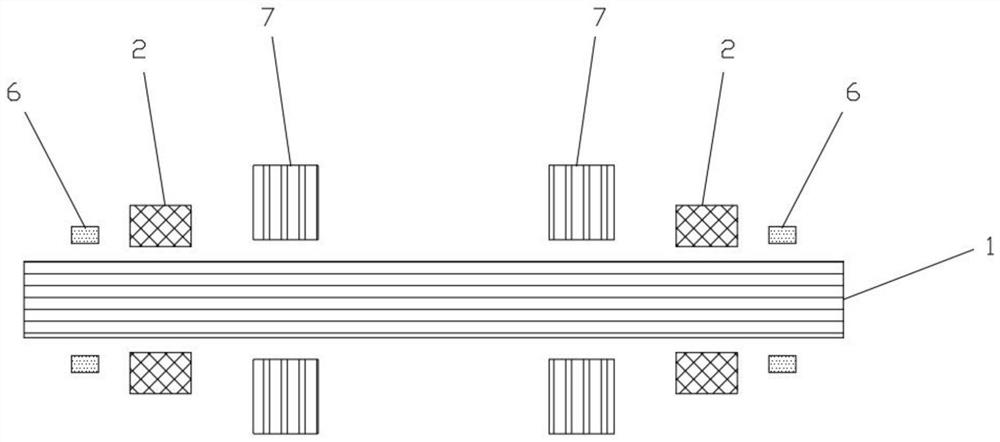

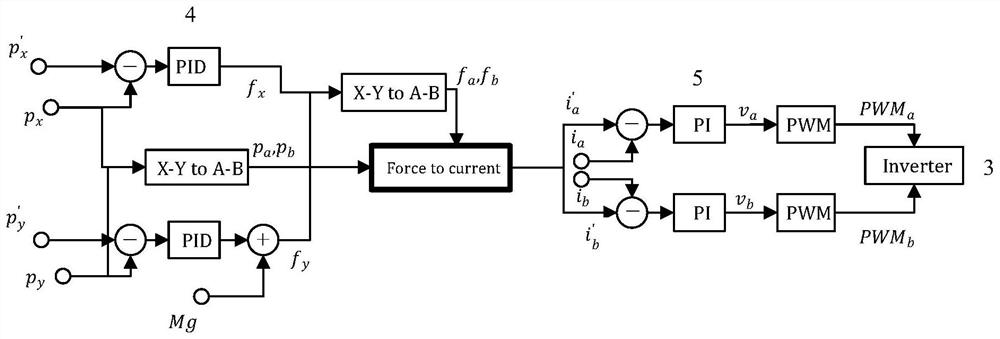

[0058] refer to Figure 1 to Figure 3 , a magnetic suspension bearing system of the present invention is assembled in a differential form, and includes a rotor 1, a ball bearing 2, a DSP controller, an inverter 3 communicating with the DSP controller, a two-position PID controller 4, and two PI The current controller 5, the IGBT is electrically connected between the PI current controller 5 and the inverter. On the radial plane of the rotor 1, take the center of the rotor as the origin, construct the X-Y coordinate system along the horizontal and vertical directions respectively, and rotate the X-Y coordinate system by 45° to construct the A-B coordinate system, and set symmetrically on the X and Y axes for measurement Two offset sensors 6 for the offset of the rotor 1 on the X and Y axes are respectively symmetrically provided with two electromagnets 7 on the A and B axes; the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com