Single-stage reciprocating piston compressor for mixed refrigerant

A mixed refrigerant and reciprocating technology, applied in the field of compressors, can solve the problems of reducing compressor efficiency and reliability, and achieve the effects of reducing friction work, improving motor efficiency, and small clearance volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

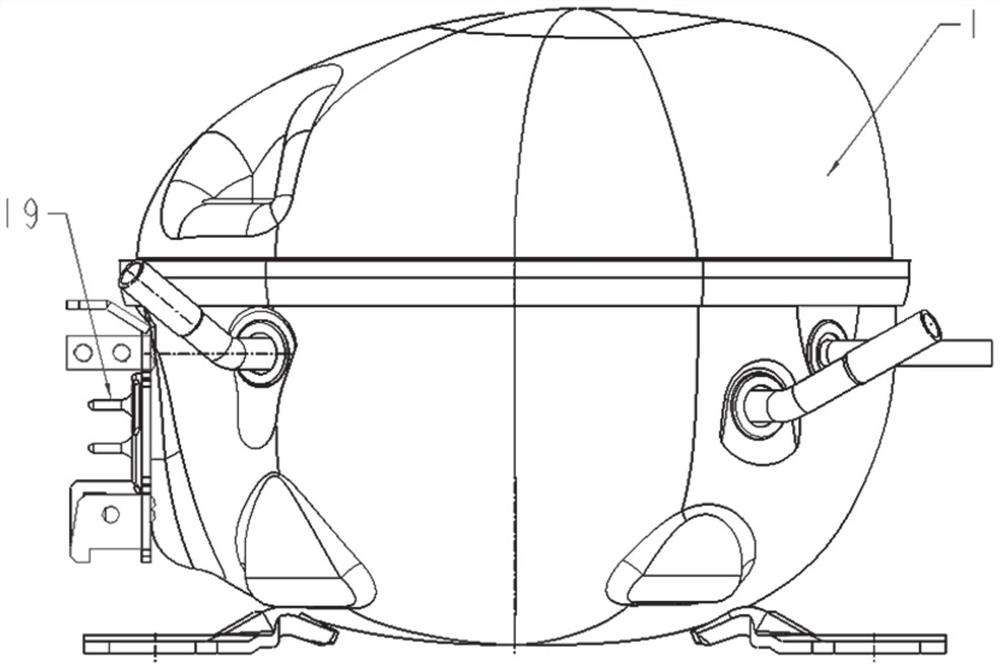

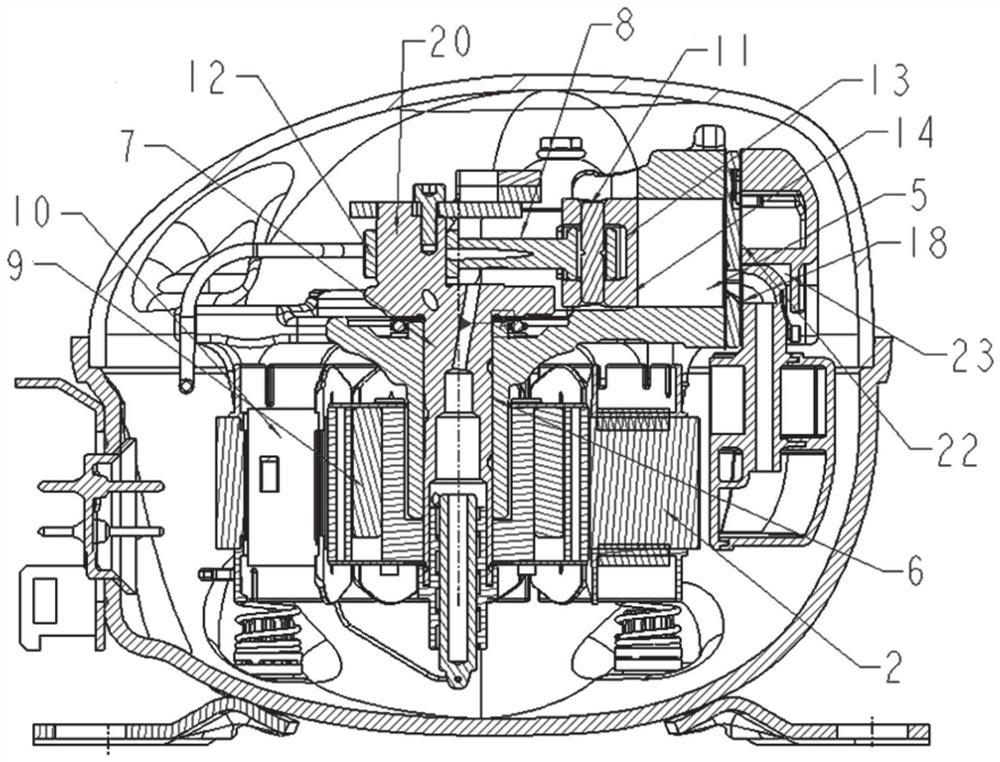

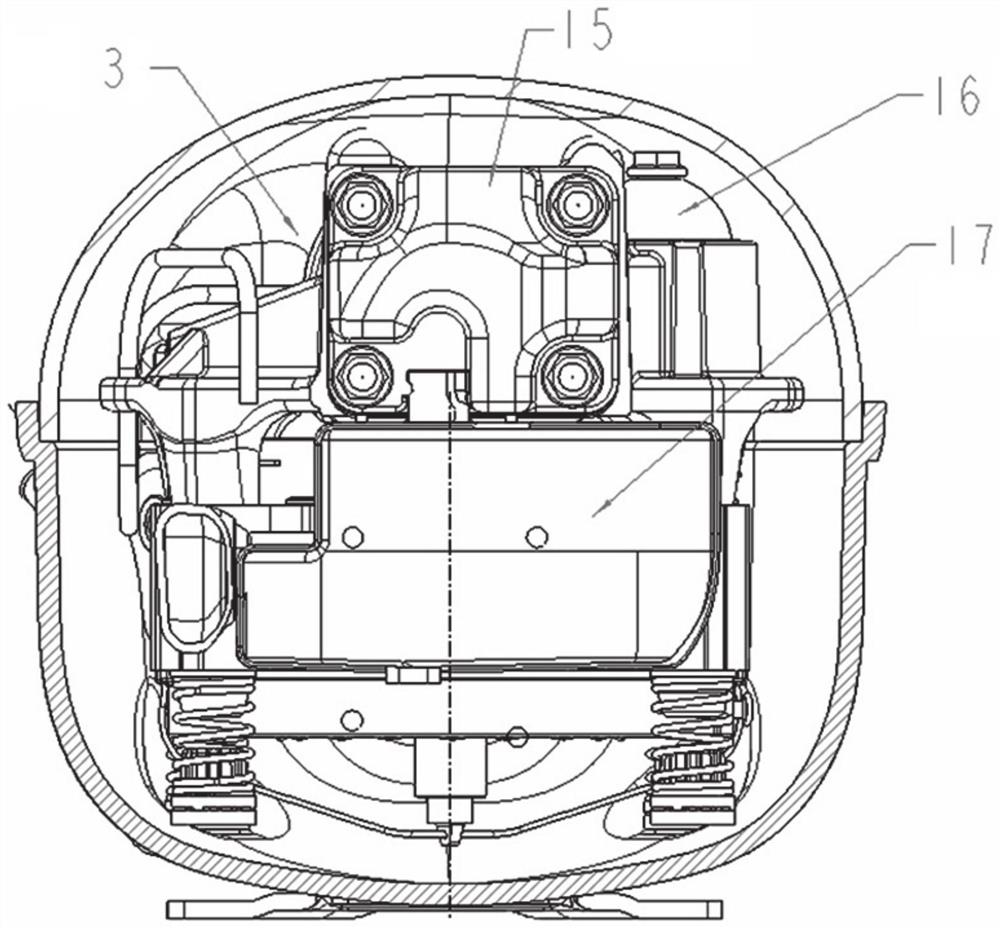

[0029] In a typical embodiment of the present invention, such as Figure 1 ~ Figure 4 As shown, in this embodiment, a single-stage reciprocating piston 14 compressor for mixed refrigerants is disclosed, which is suitable for small refrigeration systems such as refrigerators and freezers, and can meet the requirements of evaporation temperature ≤ -40°C, including the shell 1. Motor 2, pump body 3 and frequency conversion controller 4, housing 1, motor 2 and pump body 3 form a sealed body; motor 2 is connected to pump body 3 to drive pump body 3, and motor 2 is connected to frequency conversion controller 4.

[0030] The motor 2 includes a stator and a rotor 9 .

[0031] There is an inner chamber 5 in the pump body 3, which is named as a compression chamber in this embodiment because its function is compression. There is also a crankcase 6 in the pump body 3, and a crankshaft 7 and a connecting rod 8 are arranged inside the crankcase 6. , the crankcase 6 is connected with the r...

Embodiment 2

[0059] In a typical implementation of the present invention, embodiment 2 speeds up a refrigeration unit, including a single-stage reciprocating piston 14 compressor for mixed refrigerant as described in embodiment 1; also includes an evaporator and The condenser, evaporator and condenser are all communicated with the single-stage reciprocating piston 14 compressor for mixed refrigerant.

[0060] The refrigeration cycle principle of the refrigeration unit is that the compressor sucks low-temperature and low-pressure refrigerant gas from the suction pipe, and the compressor drives the piston 14 of the pump body 3 to compress the gas through the operation of the motor 2, and then discharges high-temperature and high-pressure refrigerant gas to the exhaust pipe. The refrigerant gas that powers the refrigeration cycle. In this process, the refrigerant itself circulates continuously in the refrigeration unit, and then realizes refrigeration through its own state change. The refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com