Forward construction method for oblique crossing bias tunnel

A construction method and tunnel technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as landform damage, inability to construct, and changes in tunnel entry conditions, and achieve small excavation works, strong integrity, and vertical Simple effect of slope support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A construction method for forward progress of an oblique bias tunnel, comprising the following steps:

[0033] ⑴Measuring and setting out to determine the relationship between the tunnel body and the upward slope:

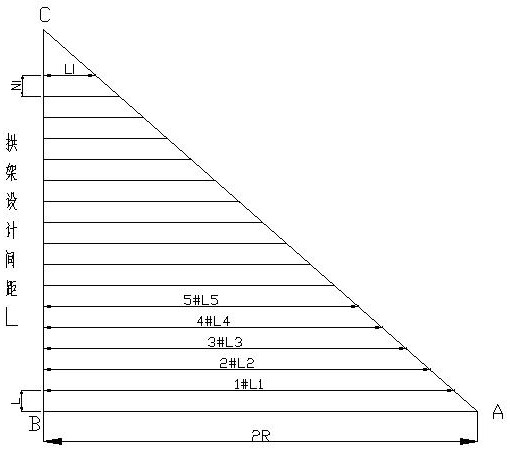

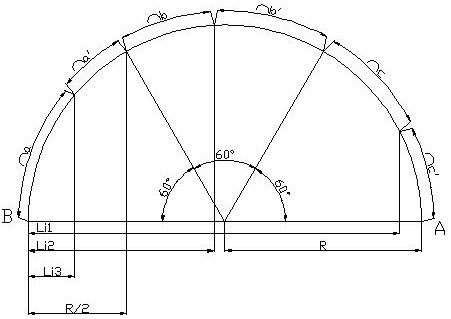

[0034] The point A on one side of the light-dark junction of the tunnel design is close to the upward slope, and the other point B is far away from the upward slope. This point B extends along the tunnel axis and intersects the upward slope at point C. The horizontal projection forms △ABC ,Such as figure 1 shown. Among them, BC is the horizontal projection of the arch foot in the direction of the tunnel entrance, AC is the horizontal projection of the oblique upward slope, and △ABC is the horizontal projection of the oblique section where the designed dark tunnel body is located outside the upward slope.

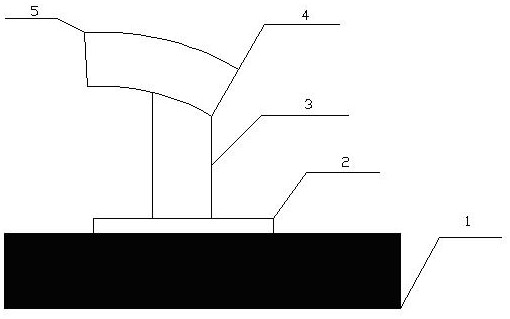

[0035] ⑵According to the AC height of the oblique upward slope, on the basis of ensuring the stability of the upward slope, the upward slope is protecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com