Anti-deflection belt conveyor

A technology of belt conveyors and belts, which is applied in the direction of conveyor objects, transportation and packaging, rollers, etc., and can solve problems such as leaking belts, affecting normal production order, and belt deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

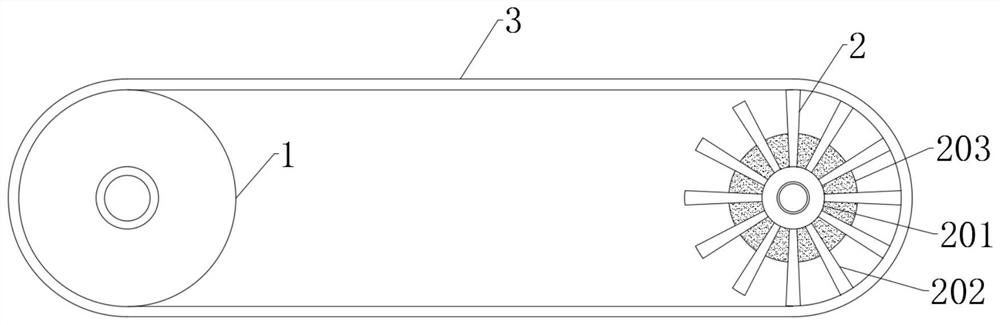

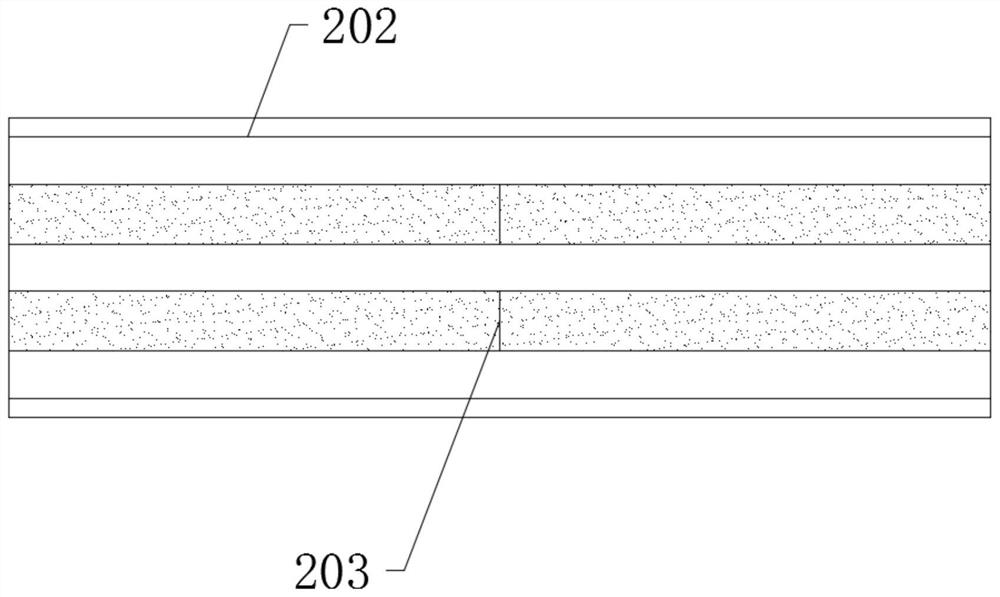

[0036] Such as Figure 1 to Figure 6 As shown, the present invention provides a kind of anti-deflection belt conveyor, comprising a driving drum 1, a rotating drum 2, and a transmission belt 3 arranged between the driving drum 1 and the rotating drum 2, characterized in that, from the rotating drum 2 to The transmission drum 1 transports the material, and the rotating drum 2 includes a rotating part 201 and a plurality of supporting parts 202 arranged in an annular array on the outer wall of the rotating part 201 for supporting the conveyor belt 3, and two adjacent supporting parts 202 are provided with wedge-shaped protrusion 203 .

[0037]When the present invention is in use, power is input at the driving drum 1 to drive the rotating drum 1 to rotate, and the static friction between the driving drum 1 and the transmission belt 3 drives the transmission belt 3 to rotate synchronously with the rotating drum.

[0038] The transmission belt 3 drives the rotating drum 2 to rotat...

Embodiment 2

[0072] Such as Figure 7 As shown, the present invention provides a method for adjusting the slack of an anti-deviation belt conveyor, comprising steps,

[0073] S100, a plurality of first detection rollers and a plurality of second detection rollers are alternately arranged between the conveying belts, and one of the first detecting rollers is arranged at the lowest point of the conveying belt;

[0074] S200, when the sensor on the first detection roller at the lowest point of sagging of the conveying belt touches the conveying belt, the control component receives the information from the sensor and adjusts all the telescopic devices of the first detecting roller to rise, and lifts up the conveying belt part;

[0075] S300. As the conveyor belt continues to run, when any of the second detection rollers detects the conveyor belt again, the control component regulates the tension adjustment mechanism to adjust the distance between the rotating drum and the driving drum.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com