Underwater sound absorption metamaterial based on novel pore cavity

A technology of metamaterials and cavities, applied in the direction of sound-generating devices, instruments, synthetic resin layered products, etc., can solve the problems of acoustic performance degradation, easy deformation, etc., to enhance water pressure resistance, meet integration requirements, and designability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

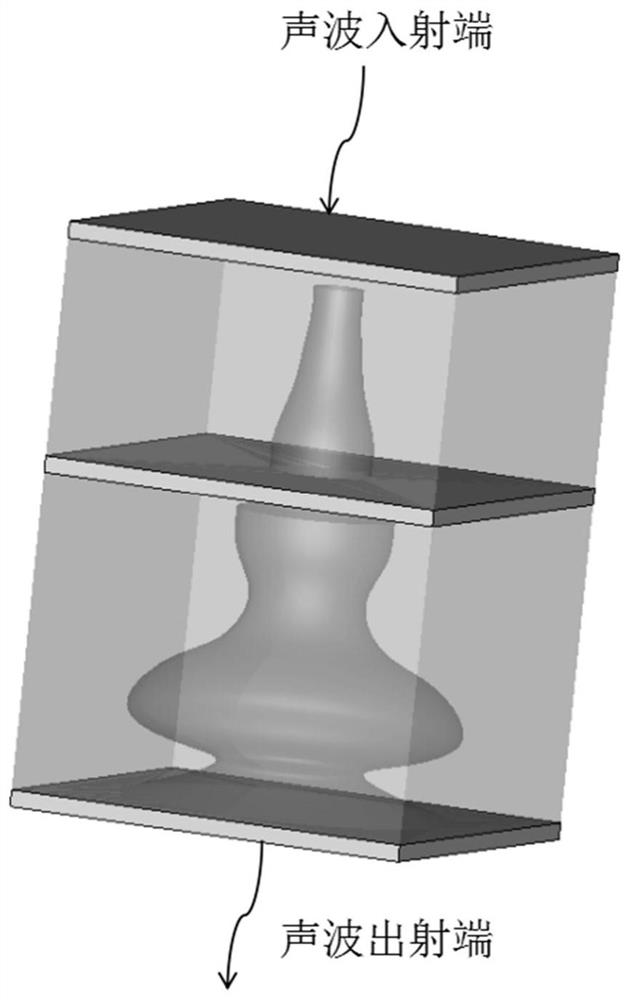

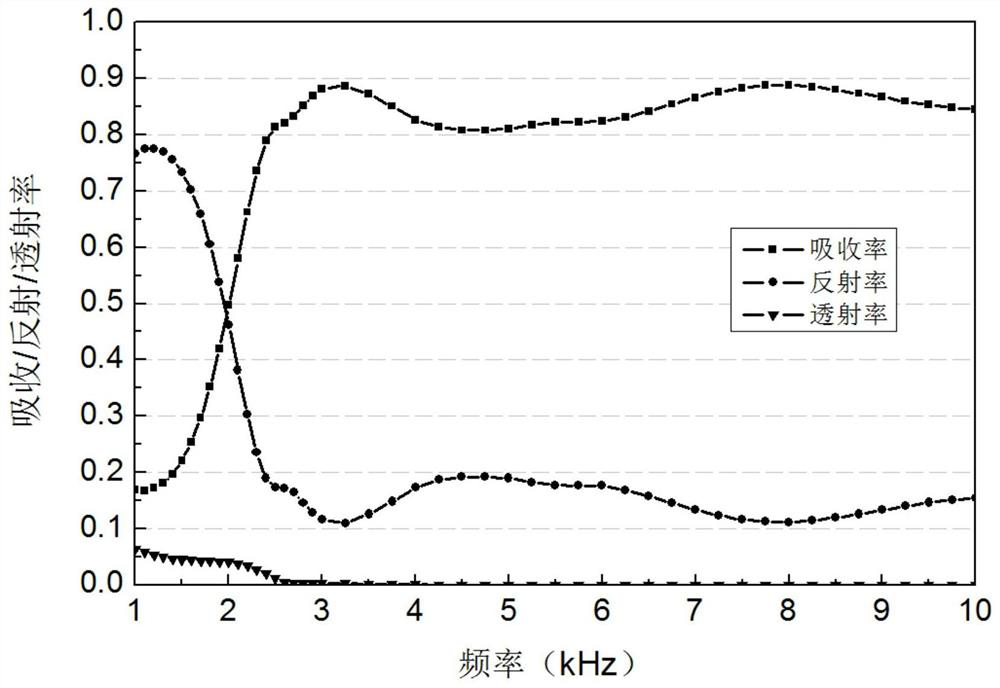

Embodiment 1

[0044] The cell side length is 50mm and the thickness is 70mm. The thickness of each layer of fiber reinforced resin panels is 2mm. The fiber reinforced resin panels are glass fiber reinforced resin materials with an elastic modulus of 18GPa, a Poisson's ratio of 0.15, and a density of 1700g / cm. 3 . The thickness of the upper and lower layers of viscoelastic polymer is 26mm and 38mm respectively, and the viscoelastic polymer is modified polyurethane with a density of 960kg / m 3 , the Young's modulus is 30MPa, the Poisson's ratio is 0.49, and the equivalent isotropic loss factor is 0.5. In the combined cavity, the bottom cavity of the upper cavity has a radius of 6mm and a height of 22mm, and the cavity radius varies between 2 and 6mm with the height; the lower cavity has a radius of 20mm and a height of 32mm, and the cavity radius changes with the height. Change between 8 and 20mm. The characteristic density of water is 1000kg / m 3 , the speed of sound is 1500m / s. The prepar...

Embodiment 2

[0047] The side length of the cell is 48mm and the thickness is 68mm. The thickness of each layer of fiber reinforced resin panels is 2mm. The fiber reinforced resin panels are carbon fiber reinforced resin materials with an elastic modulus of 80GPa, a Poisson's ratio of 0.15, and a density of 1200g / cm. 3 . The thickness of the upper and lower layers of viscoelastic polymer is 24mm and 38mm respectively, the viscoelastic polymer adopts modified polyurethane, and the density is 1100kg / m 3 , the Young's modulus is 35MPa, the Poisson's ratio is 0.49, and the equivalent isotropic loss factor is 0.45. In the combined cavity, the bottom cavity of the upper cavity has a radius of 7 mm and a height of 20 mm, and the cavity radius varies from 1 to 7 mm with the height; the lower cavity has a radius of 22 mm and a height of 30 mm. Change between 7 ~ 22mm. The characteristic density of water is 1000kg / m 3 , the speed of sound is 1500m / s. In the preparation process of underwater sound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com