A kind of gold leaf paint batch painting equipment for golden eggs

A painting equipment and gold leaf technology, applied in the direction of spraying devices, etc., can solve the problems of slow speed, frequent workers' operations, waste of gold leaf paint, etc., and achieve the effect of improving work efficiency and reducing manual actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

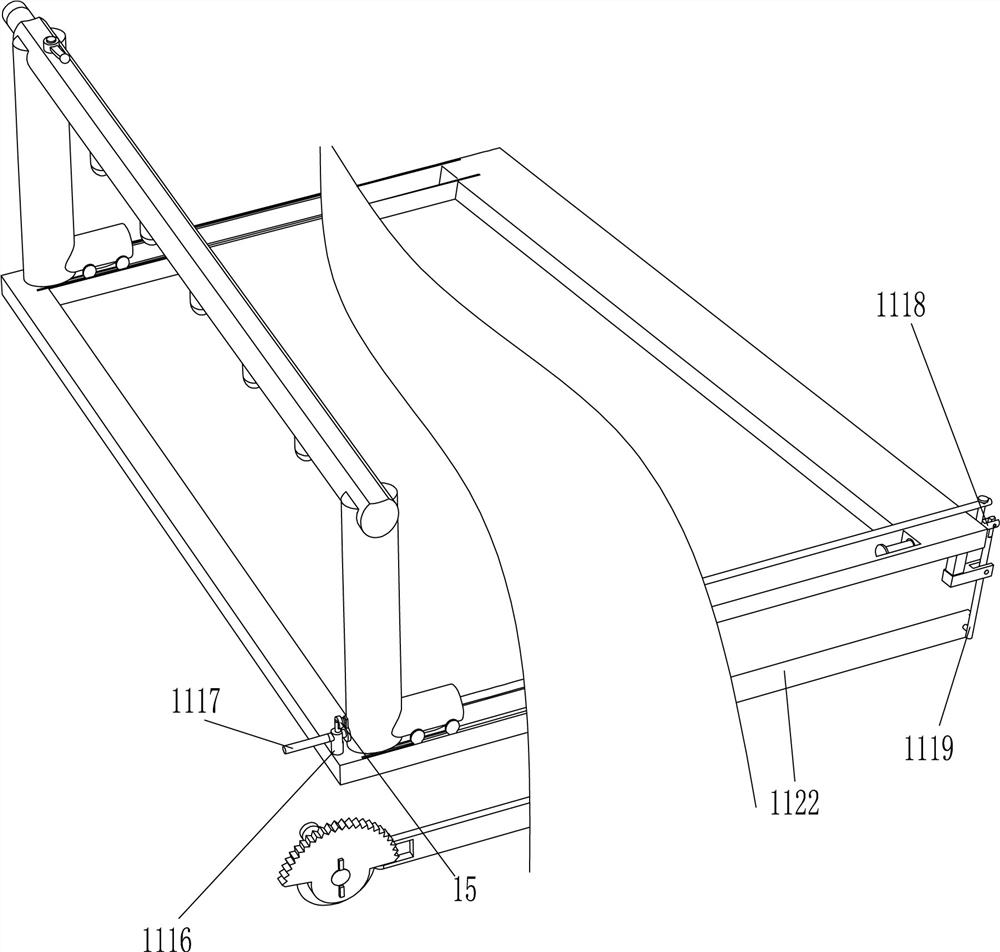

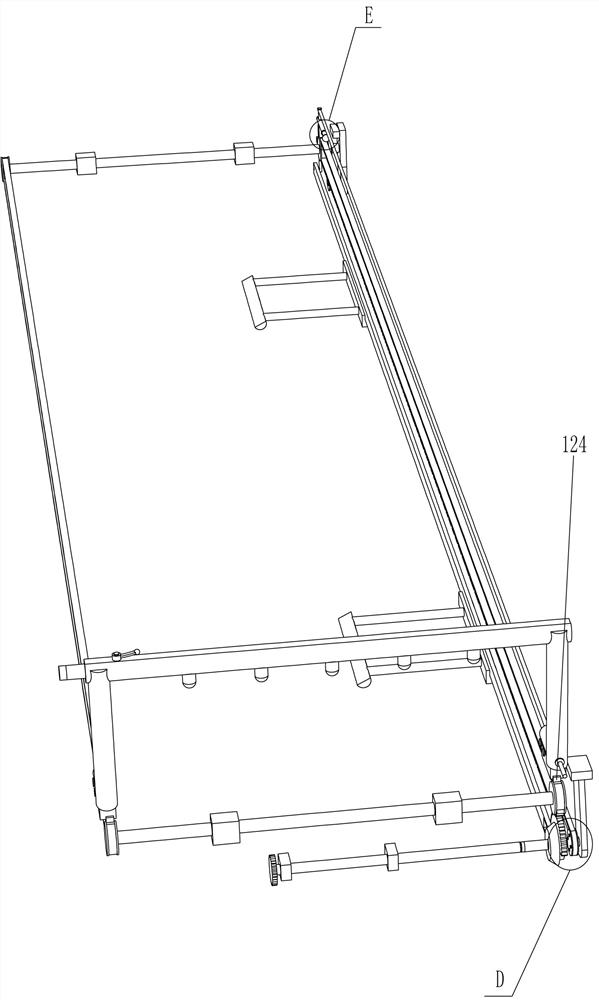

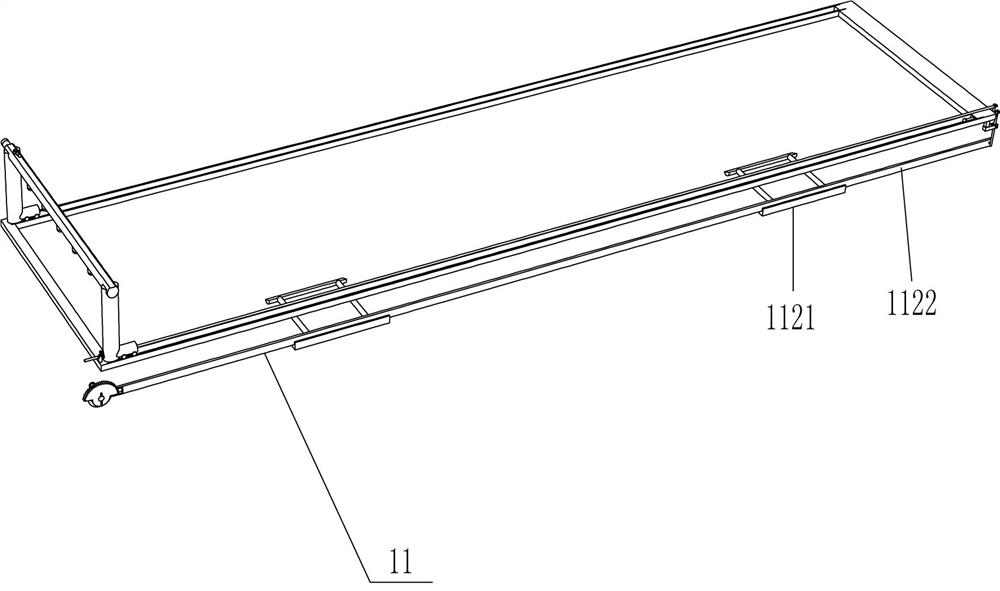

[0027] A kind of gold leaf paint batch painting equipment for golden eggs, such as Figure 1-12 As shown, it includes a housing 1, a base 2 and a placement plate 3, the bottom of the housing 1 is provided with a base 2, a placement board 3 is installed on the housing 1, and a support rod 4, a slider 6, and a storage tube 7 are also included. , nozzle 8, valve 9, guide wheel 10, driving device 11 and transmission mechanism 12, both sides of housing 1 are provided with chute 5, and slide block 6 is provided in the slide type of chute 5, and slide block 6 is connected There are support rods 4, storage pipes 7 are connected between the front and rear support rods 4, nozzles 8 are evenly spaced at the bottom of the storage pipes 7, valves 9 are installed on the top of the storage pipes 7, and the rear side of the storage pipes 7 is connected to There are external pipes, two guide wheels 10 are provided on the front and rear sides of the lower part of the pole 4, guide grooves are f...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 and 12 As shown, it also includes a conflict rod 13, a filter frame 14 and a switch 15. The conflict rod 13 is installed on the upper right rear side of the housing 1, and the conflict rod 13 is connected with the housing 1 through bolt connection, and the top of the sliding seat 1116 is installed There is a switch 15, the right side of the housing 1 is provided with an opening for flowing out the gold leaf paint, and a filter frame 14 is installed under the opening of the housing 1.

[0033] When the material storage pipe 7 moves to the right and is about to finish painting, the valve 9 contacts with the interference rod 13 to close the valve 9, and the gold leaf paint flowing from the prop egg during the painting process will flow out through the slope at the bottom of the housing 1, and the outflowing gold leaf paint will It will be filtered through the filter frame 14, so that the outflowing gold leaf paint can be reused ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com