Instant wet tissue manufacturing device and method

A production device and production method technology, which are applied to liquid/gas/vapor processing transmission devices, textile material processing equipment configuration, textile material carrier processing and other directions, can solve problems such as deterioration and unusability, deterioration and failure of wet wipes, drying and other problems, Achieve good elasticity and strength, ensure the effect of use, and ensure the effect of immediacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

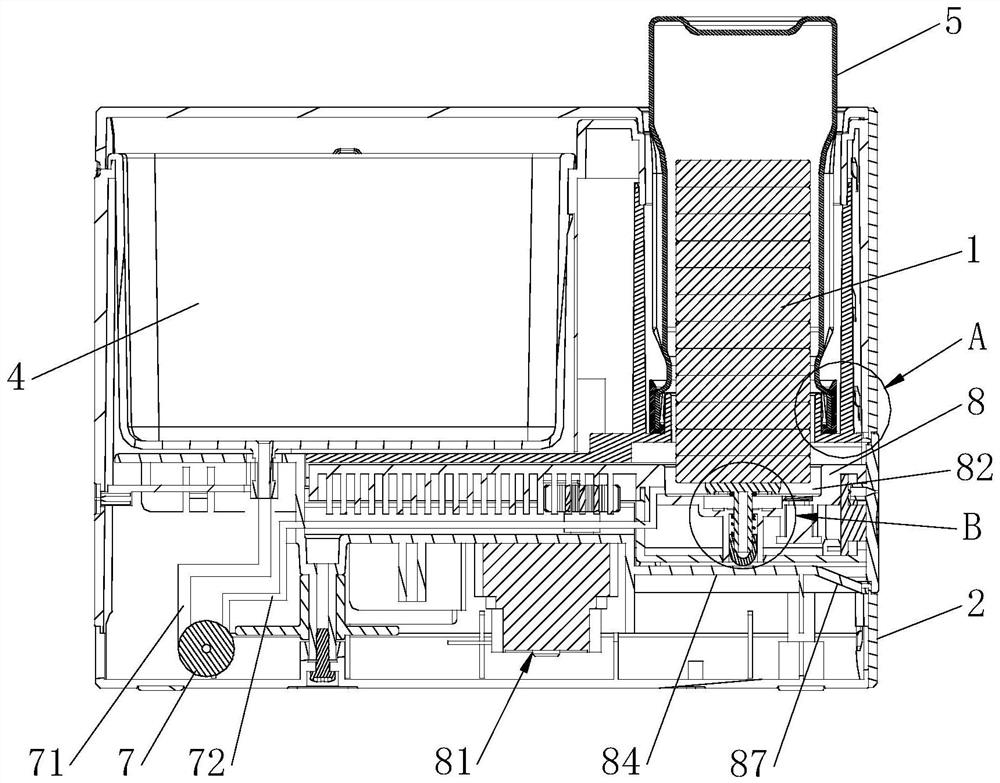

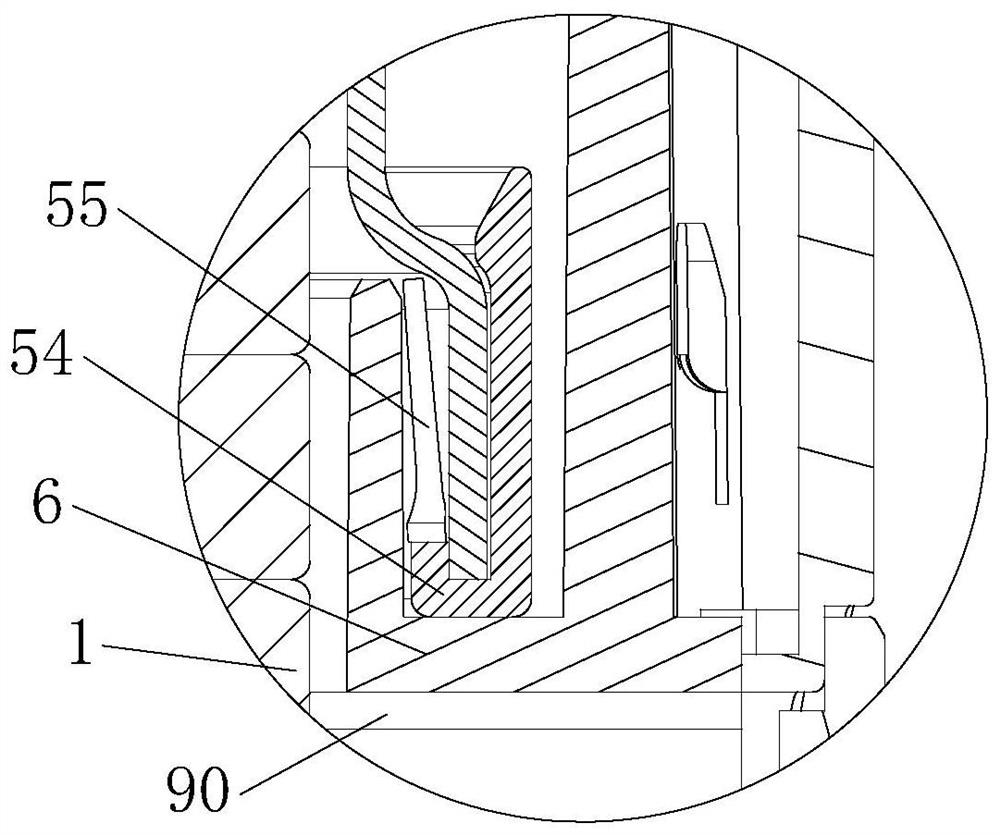

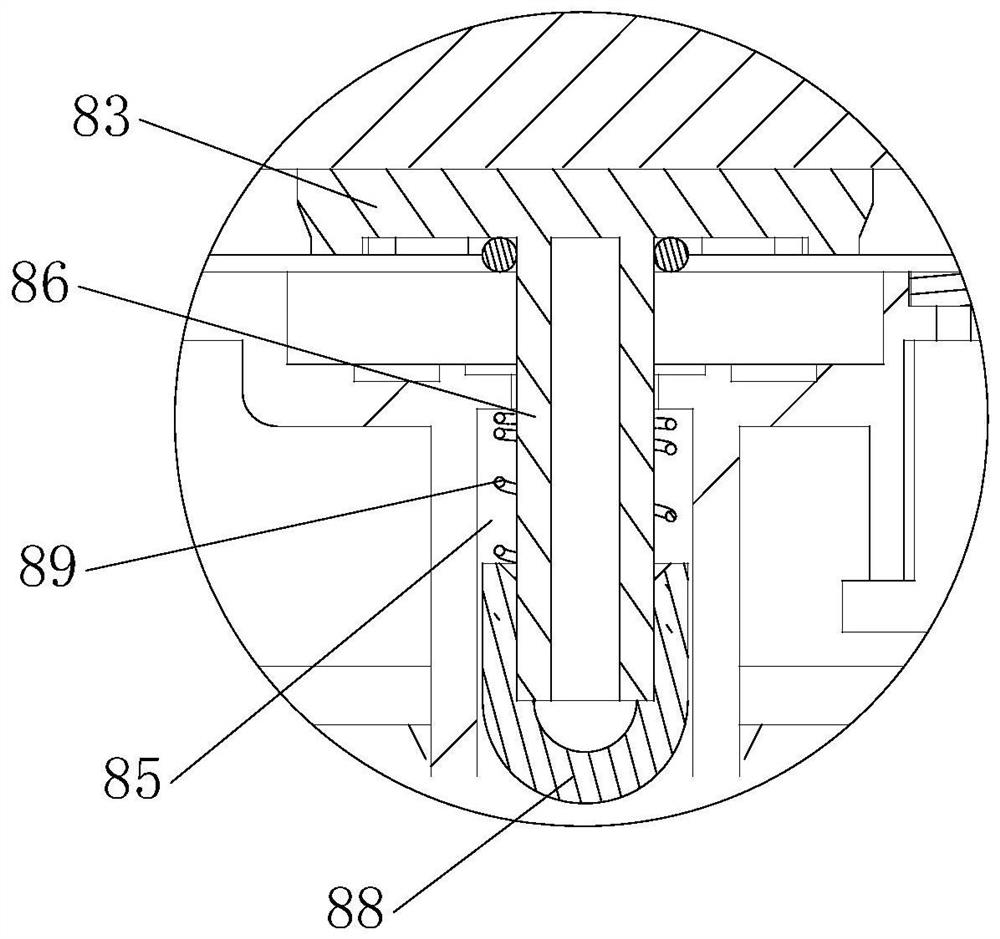

[0052] Example 1, as Figure 1-7 As shown, a device for making instant wet wipes includes a chassis 2, a control module 3, a material storage module for storing the compressed towel block 1 to be soaked, and a liquid storage module for storing the liquid soaked in the compressed towel block 1 group, the wetting area 82 for compressing the towel block 1 to be soaked, the liquid feeding module for transporting the soaking liquid in the liquid storage module to the soaking area 82, the compressed towel block 1 and the soaking liquid Separate storage, the liquid storage module in this embodiment is the liquid storage tank 4; the compressed towel block 1 is located in the chassis 2, and the chassis 2 is provided with a compressed towel block 1 to be soaked or semi-soaked compressed towel block 1 Or the compressed towel block 1 has been soaked and sent to the towel-discharging mechanism outside the chassis 2; the compressed towel block 1 of the present invention is stored separately...

Embodiment 2

[0087] Example 2, as Figure 13As shown, the difference between this embodiment and Embodiment 1 is that the instant wet wipes making device of this embodiment does not have a towel ejecting mechanism, the material storage module may not be arranged on the chassis 2, and the material storage module can be used for Any item for storing the compressed towel block 1, such as a packaging bag, a packing box, etc. for storing the compressed towel block 1, the compressed towel block 1 is arranged outside the cabinet 2, and the soaking area 82 is located outside the cabinet 2; The compressed towel block 1 is placed in the soaking area 82, and the soaking liquid in the liquid storage module is transported to the soaking area 82 through the liquid feeding module. After the compressed towel block 1 is soaked, the soaking liquid can be directly soaked. The compressed towel block 1 is taken out from the soaking area 82 without the need for the towel delivery mechanism. The remaining parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com