Top coal caving operation control device and method based on ultrasonic intensity test

A technology for strength testing and control devices, applied in mining devices, earth-moving mining, mine roof supports, etc., can solve problems such as failure, waste of coal resources, and influence on the quality of coal production, achieving good universality and avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

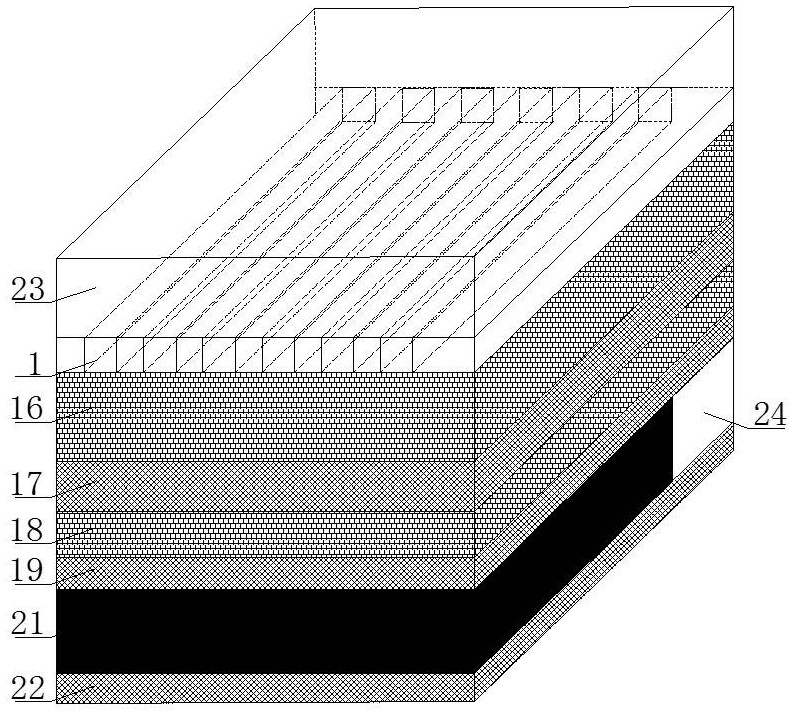

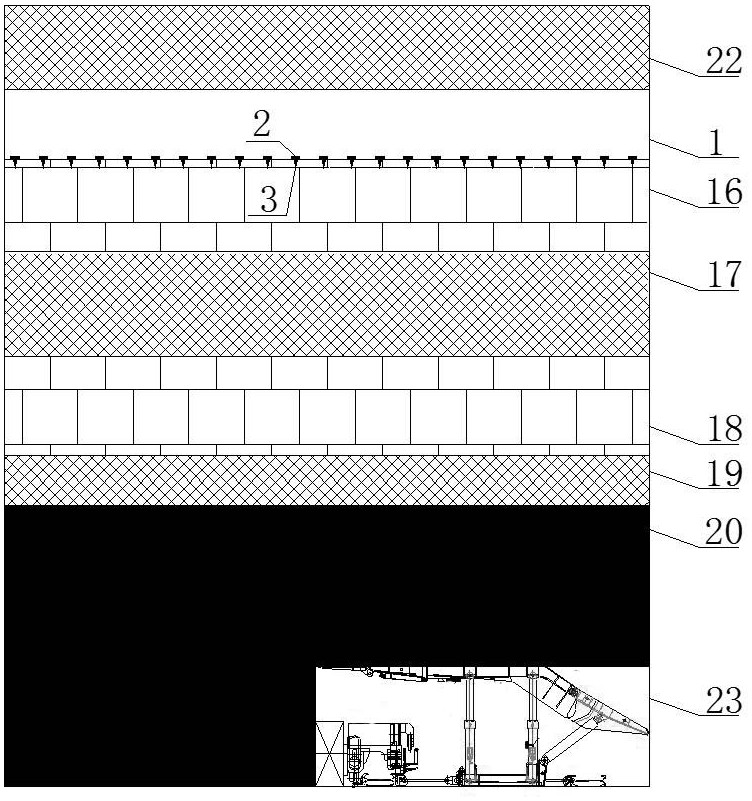

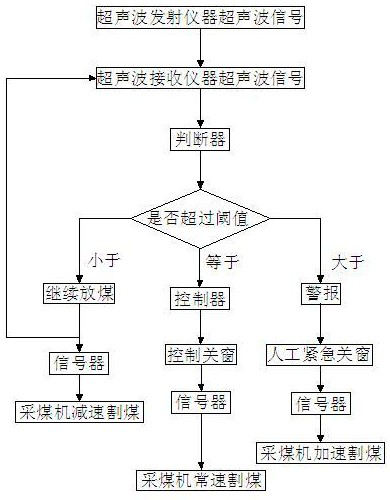

[0028] Refer to attached figure 2 A device for controlling top-coal caving operation based on ultrasonic intensity testing, including an ultrasonic transmitting system, an ultrasonic receiving and judging system, and a signal emitting system. The ultrasonic emission system includes a high-level ultrasonic layout lane 1, an ultrasonic transmitter 2 with its own power supply, and a fixing nail 3, wherein the fixing nail 3 is welded to the ultrasonic transmitter 2 with its own power supply, and fixed to the bottom plate of the high-level ultrasonic layout lane 1; The receiving result analysis system includes an ultrasonic receiver 4, a signal judger 5, and a signal transmitter 6, wherein the ultrasonic receiver 4, the signal judger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com