Processing method for reducing energy consumption of catalytic device

A processing method and technology for a catalytic device, which are applied in the petroleum industry, distillation control/regulation of hydrocarbon oil, corrosion/fouling inhibition of processing equipment, etc. problems, to achieve the effect of reasonable heat extraction efficiency, convenient operation and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

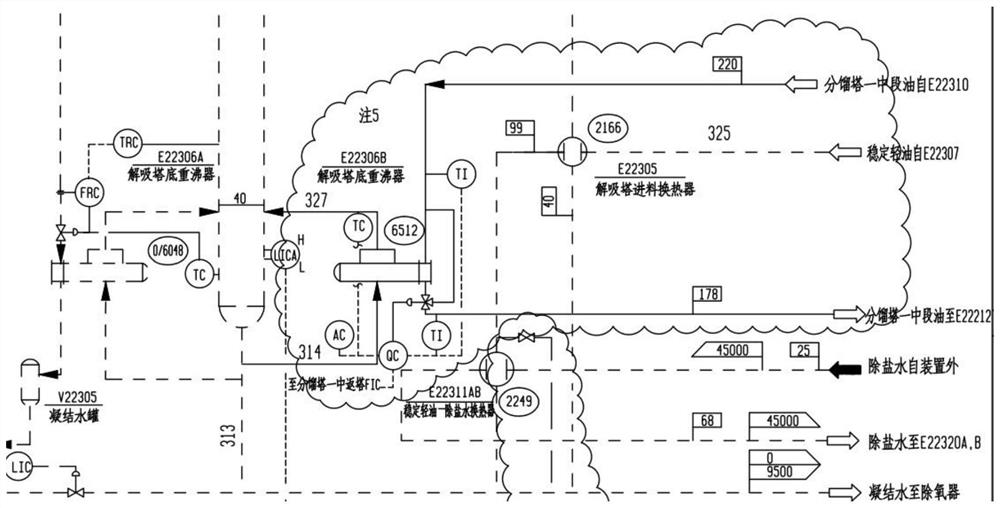

[0012] Such as figure 1 Shown, a kind of processing method that reduces the energy consumption of catalytic device, comprises the steps:

[0013] a. Equip a CNPC-super-heavy aromatics heat exchanger on the outside of the fractionation tower, and an analytical tower bottom material heat exchanger on the outside of the desorption tower. A CNPC-super-heavy aromatics heat exchanger is connected to the fractionation tower and the desorption tower The bottom material heat exchanger is connected to the desorption tower through pipelines;

[0014] b. After the circulating superheavy aromatics come out of the pump, they first pass through a medium oil-superheavy aromatics heat exchanger to exchange heat with a medium oil, and take out the high-level heat energy of the superheavy aromatics;

[0015] c. According to the original technological process, the heated Yizhong oil first exchanges heat with the material in the material heat exchanger at the bottom of the desorption tower before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com