Polyimide diaphragm and preparation method thereof

A technology of polyimide and polyamic acid is applied in the field of polyimide diaphragm and its preparation, which can solve the problems of high temperature resistance, deformation, and potential safety hazards of power lithium battery of the diaphragm, so as to achieve good rigidity, flexibility, simple process, The effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

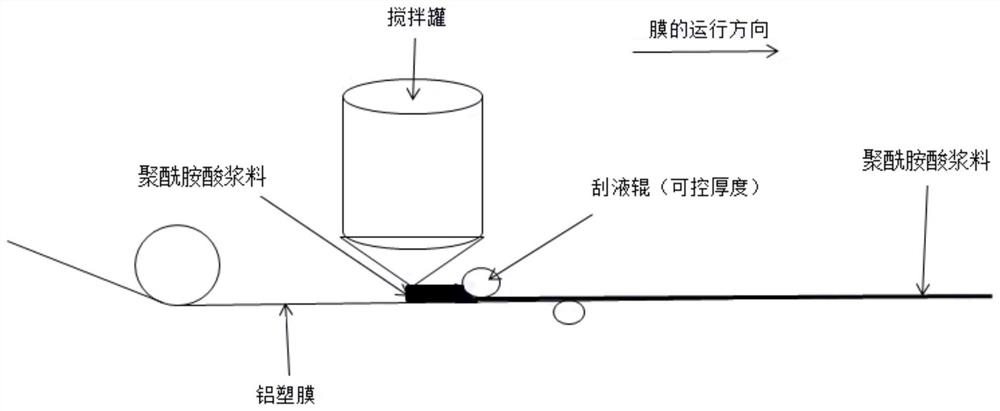

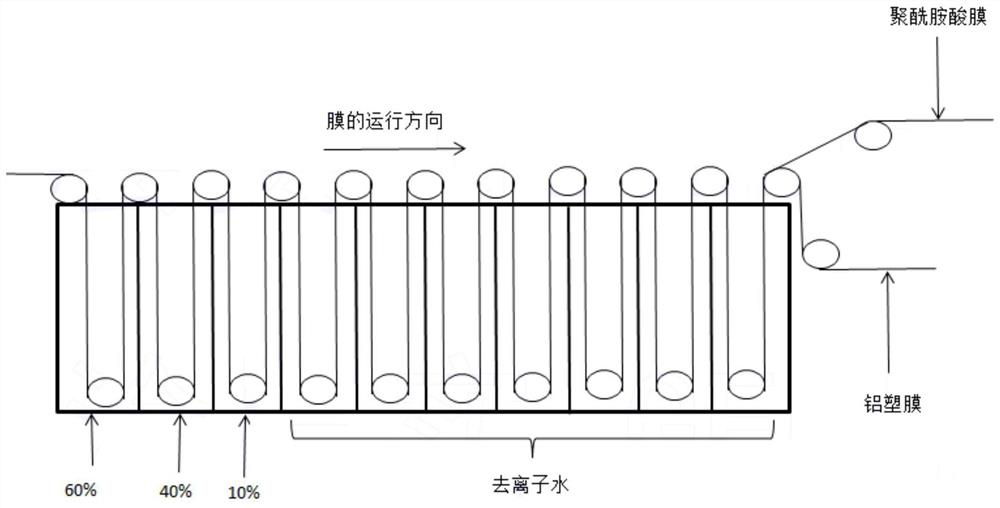

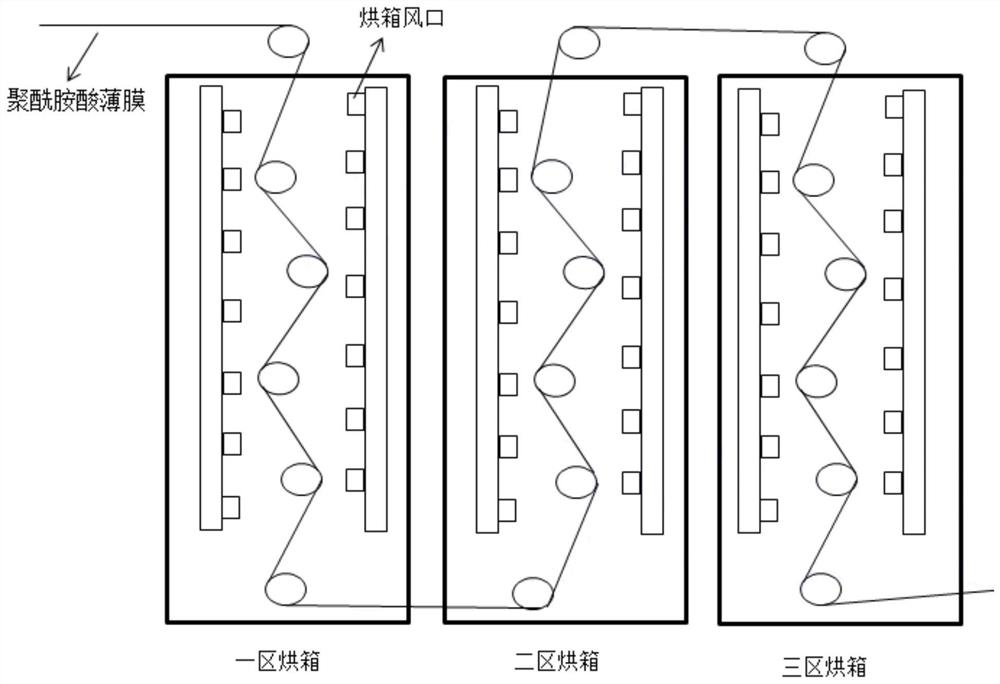

[0048] A kind of preparation method of polyimide diaphragm of the present invention, comprises the following steps:

[0049]Step 1: under the condition of nitrogen protection, add the N-methylpyrrolidone after dehydration into the reaction tank, then add p-phenylenediamine into the reaction tank, stir at 30r / min for 15min to fully dissolve the p-phenylenediamine, and obtain The first mixed solution; feed chilled water into the jacket of the reaction tank, after cooling the first mixed solution in the reaction tank to 7°C, add pyromellitic dianhydride to the first mixed solution to obtain For the second mixed solution, the temperature of the second mixed solution is gradually raised to 15° C. and maintained at this temperature, and stirred at 30 r / min for 20 minutes to fully carry out the reaction in the second mixed solution to obtain a polyamic acid solution; wherein, in the In the second mixed solution, the mass fraction of N-methylpyrrolidone is 95wt%, the total mass fracti...

Embodiment 2

[0061] A kind of preparation method of polyimide diaphragm of the present invention, comprises the following steps:

[0062] Step 1: Under the condition of nitrogen protection, add the dehydrated N-methylpyrrolidone into the reaction tank, then add 4,4-diaminodimethyl ether into the reaction tank, stir at 35r / min for 18min to make 4,4 -Diaminodimethyl ether is fully dissolved to obtain the first mixed solution; into the jacket of the reaction tank, chilled water is passed, and after the first mixed solution in the reaction tank is cooled to 10°C, the first mixed solution is added to the first mixed solution Pyromellitic dianhydride was added to obtain the second mixed solution, and the second mixed solution was gradually warmed up to 18°C and kept at this temperature, stirred at 35r / min for 20min to fully proceed the reaction in the second mixed solution, and obtained Polyamic acid solution; wherein, in the second mixed solution, the mass fraction of N-methylpyrrolidone is 9...

Embodiment 3

[0074] A kind of preparation method of polyimide diaphragm of the present invention, comprises the following steps:

[0075] Step 1: Under the condition of nitrogen protection, add the N-methylpyrrolidone after dehydration into the reaction tank, then add p-phenylenediamine into the reaction tank, stir at 40r / min for 20min to fully dissolve the p-phenylenediamine, and obtain The first mixed solution; into the jacket of the reaction tank, chilled water is passed, and after the first mixed solution in the reaction tank is cooled to 12°C, 3,3,4,4- Biphenyltetracarboxylic dianhydride to obtain the second mixed solution, gradually warming the second mixed solution to 20°C and maintaining the temperature, stirring at 40r / min for 20min to fully proceed the reaction in the second mixed solution to obtain polyamide acid solution; wherein, in the second mixed solution, the mass fraction of N-methylpyrrolidone is 95wt%, and the total mass fraction of p-phenylenediamine and 3,3,4,4-biphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com