Preparation method of nonlinear CsPbX3 nanocrystalline glass

A nanocrystalline, nonlinear technology, applied in the field of nonlinear optics, can solve the problem of nonlinear refractive index to be improved, and achieve the effect of convenient synthesis method, strong stability, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Table 1: Raw material formula (mol%) of glass

[0056]

[0057] First, weigh according to the molar percentages of the raw materials shown in Table 1, mix them well, put them in a muffle furnace, raise them from room temperature to 1280°C in 150 minutes, and keep them warm for 30 minutes. The molten glass is then poured onto a 350°C grinder. Then put it into an annealing furnace at 360°C for 200 minutes to eliminate internal stress. After naturally cooling to room temperature, the slices were polished and then heat-treated at 470°C for 10 hours. After the temperature dropped to room temperature, the glass was cut into small circular pieces with a diameter of 1.5nm and a thickness of 0.8mm and polished on both sides, and then the obtained nanocrystalline glass was subjected to structural analysis related tests.

Embodiment 2

[0059] Referring to Example 1, the difference is that the heat treatment condition is: heat treatment at 500° C. for 10 h.

Embodiment 3

[0061] Referring to Example 1, the difference is that the heat treatment condition is: heat treatment at 530° C. for 10 h.

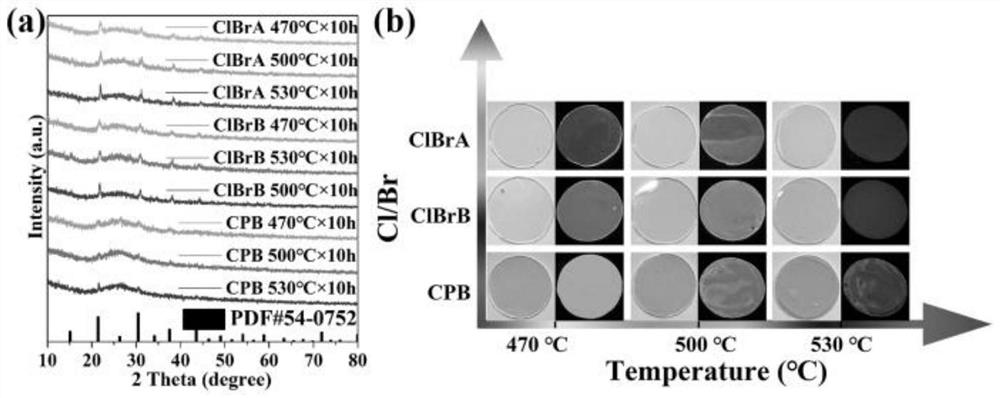

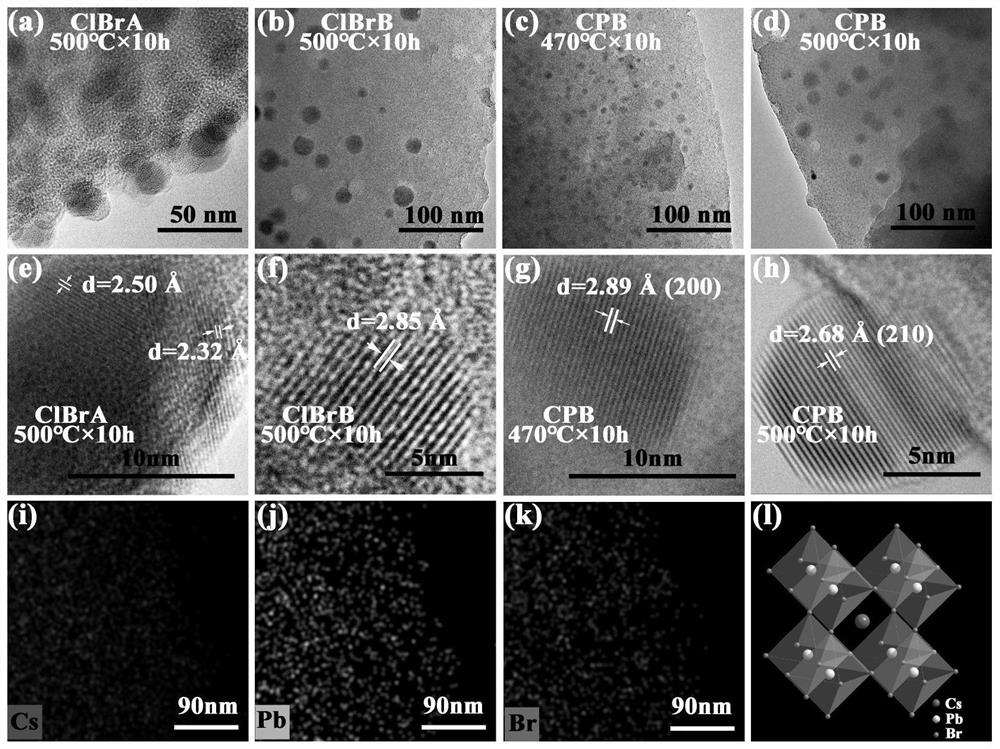

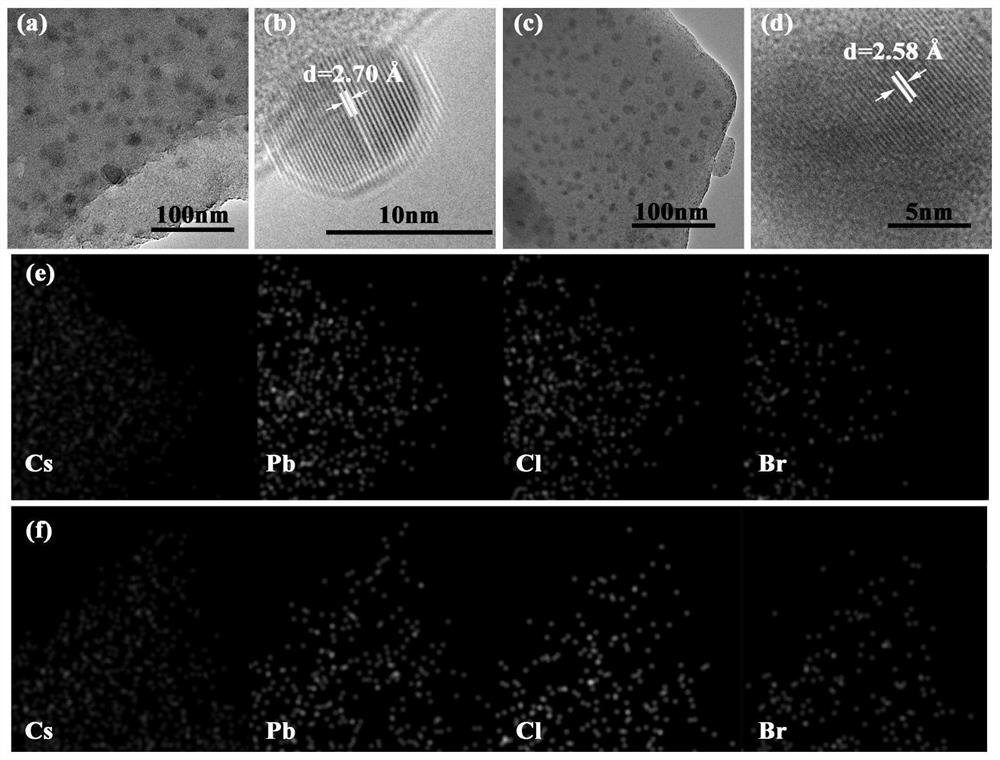

[0062] The ClBrA that embodiment 1-3 prepares, the X-ray diffraction pattern of ClBrB and CPB glass is as figure 1 (a) shown. By changing the ratio of Cl and Br, the corresponding diffraction peaks will slowly shift to higher angles following Vegard's law. Obviously, all the diffraction peaks of CPBNCs glass can be compared with CsPbBr 3 (PDF #54-0752), in addition, the diffraction peaks become clearer when the heat treatment temperature is gradually increased. The results show that increasing the heat treatment temperature leads to better crystallinity. However, too high heat treatment temperature will lead to concentration quenching, the photo of the corresponding sample is shown in figure 1 (b) shown. exist figure 2 (a)-(d) and image 3 In (a)–(c), transmission electron microscopy (TEM) analysis confirmed that the perovskite nanocrystals were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com